Manufacturing method for single ZnO micron wire homojunction light emitting diode

A technology of light-emitting diodes and micro-wires, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of not having a single ZnO micro-wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

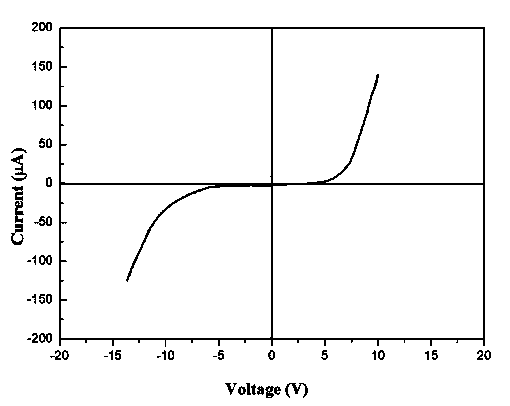

Image

Examples

Embodiment 1

[0020] a. Fully mix ZnO powder and C powder with a purity greater than 99% according to the mass ratio of 2:1 to make the reaction source material, put the reaction source material into the quartz boat, and then put the quartz boat into the growth chamber of the chemical vapor deposition system The high temperature heating zone, the silicon substrate is located 20cm below the reaction source material;

[0021] The substrate can be zinc oxide, gallium nitride, sapphire, silicon carbide, silicon, gallium arsenide, indium phosphide, calcium fluoride, quartz, glass and metal, or it can be directly lined with the inner wall of the quartz tube of the chemical vapor deposition system end;

[0022] b. Introduce high-purity argon as the carrier gas, the flow rate of argon gas is 50ml / min, when the temperature is heated to 1000°C, inject oxygen, the flow rate of oxygen is 25ml / min, start the growth of n-type ZnO micron wires, the growth time 15 minutes;

[0023] c. Turn off the oxygen...

Embodiment 2

[0030] The method is basically the same as in Example 1, except that the two growth temperatures are both 950°C. The scanning electron micrographs of the obtained samples are as follows: image 3 shown. From image 3 It can be seen that some micron wires are formed on the surface of the sample, but the length of the micron wires is relatively short (5mm), and the orientation is not as good as that of Example 1.

Embodiment 3

[0032] The method is basically the same as in Example 1, except that the two growth temperatures are both 1100°C. The scanning electron micrographs of the obtained samples are as follows: Figure 4 shown. From Figure 4 It can be seen that a large number of micron wires are formed on the surface of the sample, but the length of the micron wires is relatively short (10 mm), and the orientation is not as good as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com