A method of preparing superhydrophobic polymer surface by thermal spraying template method

A polymer, thermal spraying technology, applied in coating, melt spraying, metal material coating process and other directions, can solve the problems of limited superhydrophobic surface area, insufficient membrane strength, expensive equipment, etc., to achieve easy large-area preparation, Environmentally friendly and reproducible, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Place a thermal spray stencil on a flat substrate.

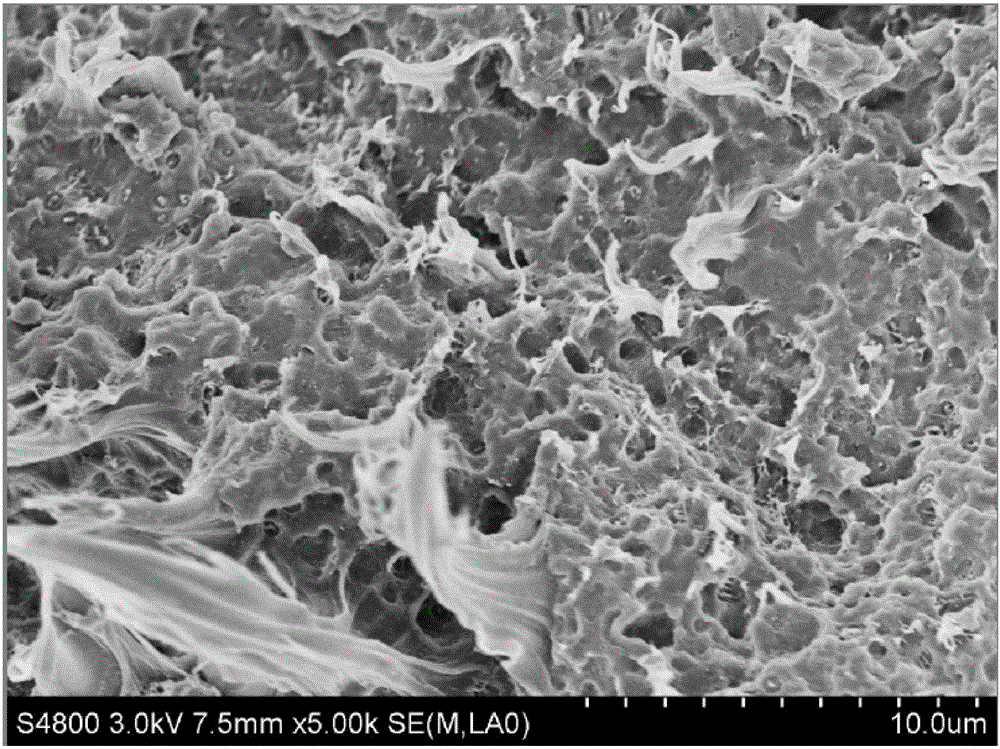

[0041] The plane base is a high temperature resistant material, and the high temperature resistant material in this embodiment is an aluminum plate. The microstructure morphology of the thermal sprayed template is as follows: figure 1 shown. The substrate of the thermal spraying template is made of stainless steel, and the surface spraying particles of the thermal spraying template are made of cemented carbide. In this embodiment, the cemented carbide is selected from tungsten carbide with a particle size of 20um. The body is made of nickel powder. from figure 1 It can be seen that the template is a micro-nano composite structure, which forms a micro-nano composite structure on the printed polymer surface after thermal transfer, and this structure is the basic condition for forming a super-hydrophobic surface.

[0042] Step 2: Lay a layer of polypropylene sheet on the thermal spray template, polypropylene ...

Embodiment 2

[0045] Step 1: Place a thermal spray stencil on a flat base substrate.

[0046] The plane base is a high temperature resistant material, and the high temperature resistant material in this embodiment is an aluminum plate. The microstructure morphology of the thermal sprayed template is as follows: figure 1shown. The substrate of the thermal spraying template is aluminum alloy, and the surface spraying particles of the thermal spraying template are selected from cemented carbide. In this embodiment, the cemented carbide is tungsten carbide, and the particle size is 30um. The body is nickel powder. It can be seen that the thermal spray template is a micro-nano composite structure, which forms a micro-nano composite structure on the printed polymer surface after thermal transfer, and the micro-nano composite structure is the basic condition for forming a super-hydrophobic surface.

[0047] Step 2: Lay a layer of polypropylene sheet on the thermal spray template, polypropylene ...

Embodiment 3

[0051] Step 1: Place a thermal spray stencil on a flat substrate.

[0052] The plane base is a high temperature resistant material, and the high temperature resistant material in this embodiment is an aluminum plate. The thermal spraying template is placed on the aluminum substrate, and the microstructure of the thermal spraying template is as follows figure 1 shown. The substrate of the thermal spraying template is made of stainless steel, and the particles sprayed on the surface of the thermal spraying template are made of cemented carbide. In this embodiment, the cemented carbide is tungsten carbide, and the aluminum plate and tungsten carbide powder are bonded by a bonding body, which is nickel powder. . It can be seen that the template is a micro-nano composite structure, which forms a micro-nano composite structure on the printed polymer surface after thermal transfer, and the micro-nano composite structure is the basic condition for forming a super-hydrophobic surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com