Preparation method of carbon aerogel adsorbent for oil contamination treatment and prepared carbon aerogel adsorbent

A carbon aerogel and carbon hydrogel technology, which is applied in adsorption water/sewage treatment, separation methods, other chemical processes, etc., can solve the problems of complex synthesis methods, high requirements for synthesis conditions, and expensive raw materials, and achieve a simple process. , low cost, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

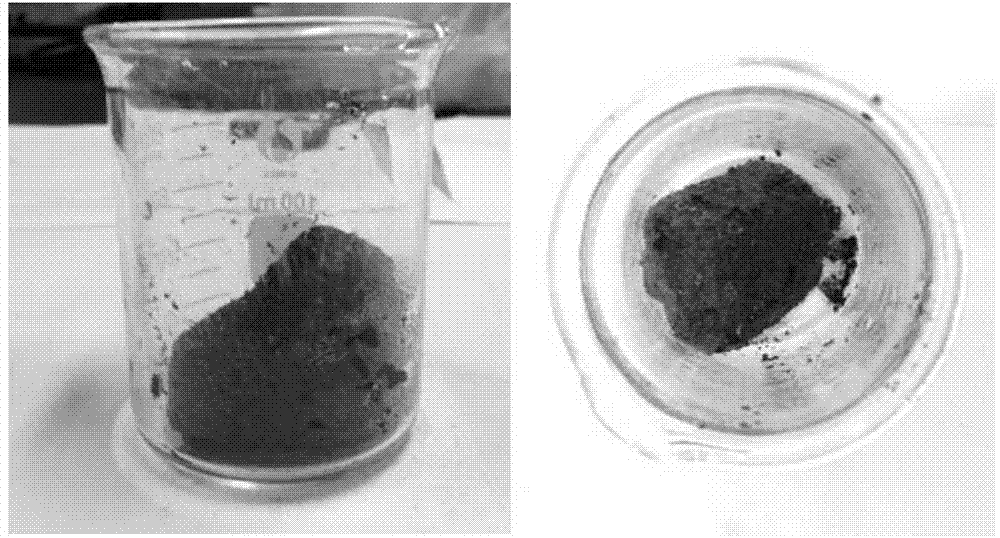

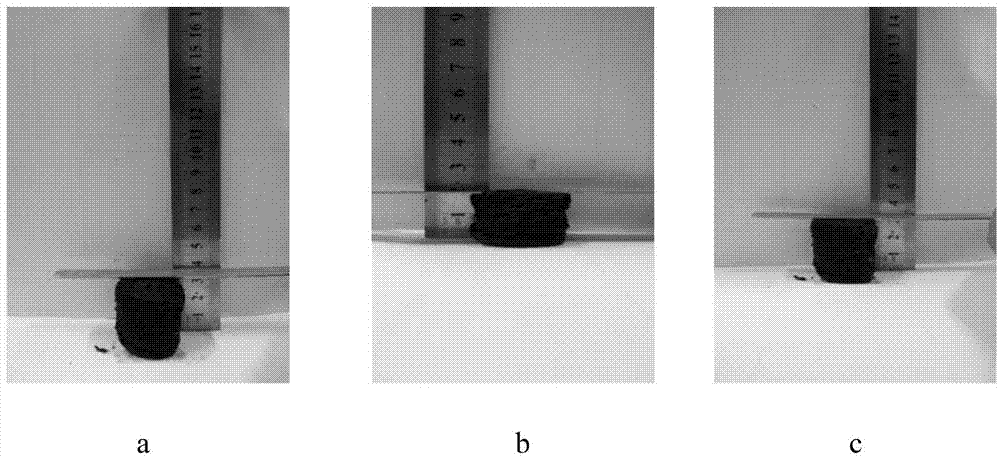

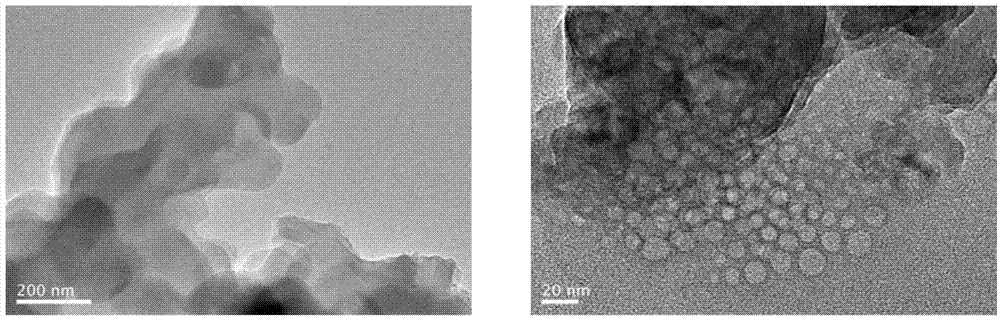

[0025] Cut the melon raw material into a suitable shape and put it in a polytetrafluoroethylene hydrothermal reaction kettle, and place it in a homogeneous reactor at a temperature of 180°C for a hydrothermal reaction for 12 hours. After the reaction is complete, slowly cool to room temperature, and finally undergo repeated water heating. Washing and washing with ethanol; a carbon hydrogel is obtained. The carbon hydrogel wrapped in tinfoil was quickly frozen in liquid nitrogen at 77K, and then dried in a vacuum oven at a constant temperature of 25 °C for 12 hours to obtain a black spongy melon carbon airgel material.

Embodiment 2

[0027] Cut the raw material of watermelon pulp into a suitable shape and put it in a polytetrafluoroethylene hydrothermal reaction kettle, and conduct a hydrothermal reaction at a temperature of 180°C for 12 hours. After the reaction is complete, it is slowly cooled to room temperature, and finally washed with water and ethanol repeatedly; The wrapped carbon hydrogel was quickly frozen in liquid nitrogen at 77K, and then dried in a vacuum oven at a constant temperature of 25°C for 12 hours to obtain a black spongy watermelon pulp carbon airgel material.

Embodiment 3

[0029] Cut the loofah raw material into a suitable shape and put it in a polytetrafluoroethylene hydrothermal reaction kettle, and place it in a homogeneous reactor at a temperature of 180°C for a hydrothermal reaction for 12 hours. After the reaction is complete, slowly cool to room temperature, and finally repeat Washing with water and ethanol; after rapid freezing in liquid nitrogen at 77K, drying in a vacuum oven at a constant temperature of 25°C for 12 hours to finally obtain a black sponge-like loofah carbon airgel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com