Copper sculpture paint with characteristics of heat resistance, ultraviolet resistance and aging resistance

An anti-ultraviolet and copper sculpture technology, applied in the field of paint, can solve the problems of easy oxidation and corrosion, affecting the appearance and service life, etc., and achieve the effects of fast drying of the paint film, good adhesion and simple production process

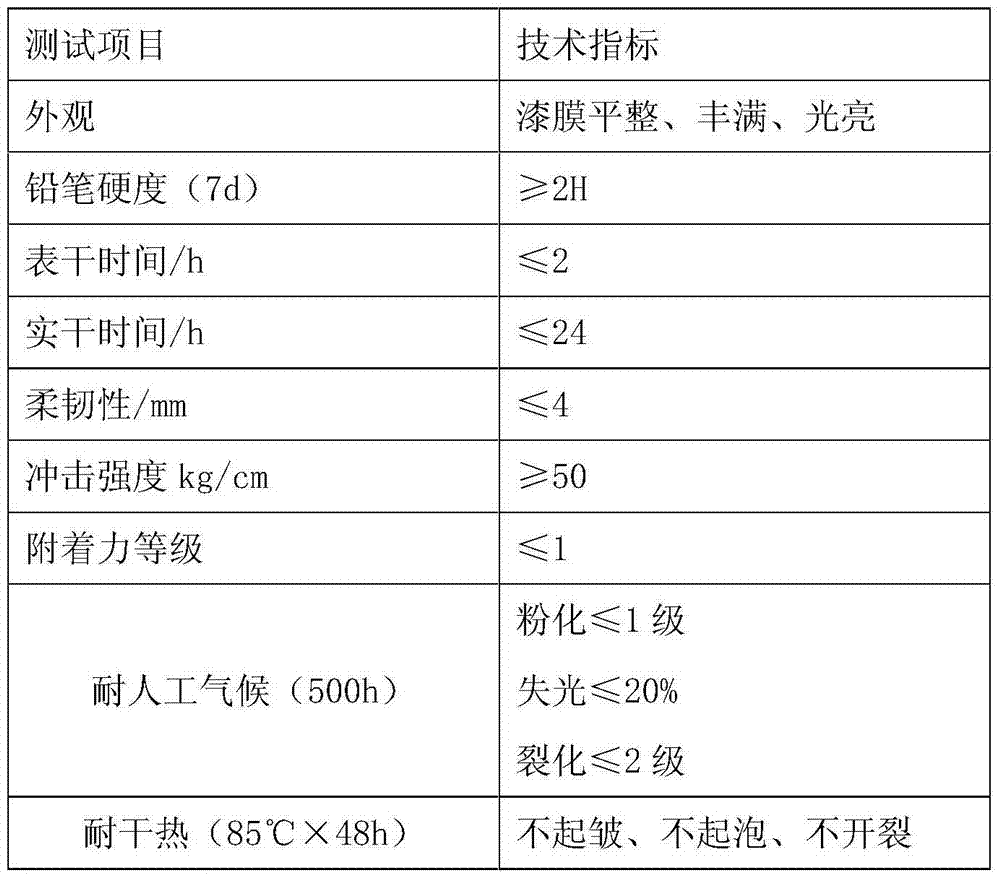

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] The paint of this embodiment is made of the following raw materials in parts by weight: silver powder 3, polyurethane resin 23, polyepoxysuccinic acid 2, dodecanoic acid 3, polyester acrylate 32, trimethylolpropane triacrylate 15, dipentaerythritol six Acrylate 6, polyhydroxyethyl methacrylate 13, vinyl tar 2, coumarone 8, accelerator CBS1.5, 1,6-hexamethylene diisocyanate 6, anilinomethyltriethoxysilane 3, ethyl acrylate 6. 5 m-aminomethylamine, 6 additives, 12 xylene, 12 butyl acetate.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: clay 10, magnesium oxide 4, zinc oxide 2, bauxite 6, vanadium carbide 2, accelerator TMTM3, jade 4, anilinomethyltriethoxysilane 3 , dimethyl isophthalate 40, propyl gallate 2, coix seed oil 3, epicatechin 2; the preparation method is to put clay, bauxite, and jade into a calciner for calcination at 720-740°C 3 hours, then take it out, put it in 15% hydrochloric acid solution and soak it for 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com