Core-shell nanofiber wrapping lipidosome

A technology of nanofibers and liposomes, which is applied to core-shell nanofibers containing liposomes in the core layer. In the field of preparation, it can solve the problems of unfavorable controlled release of contents, leakage of contents, rupture of liposomes, etc., and achieve good results. The effect of biocompatibility, low price, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

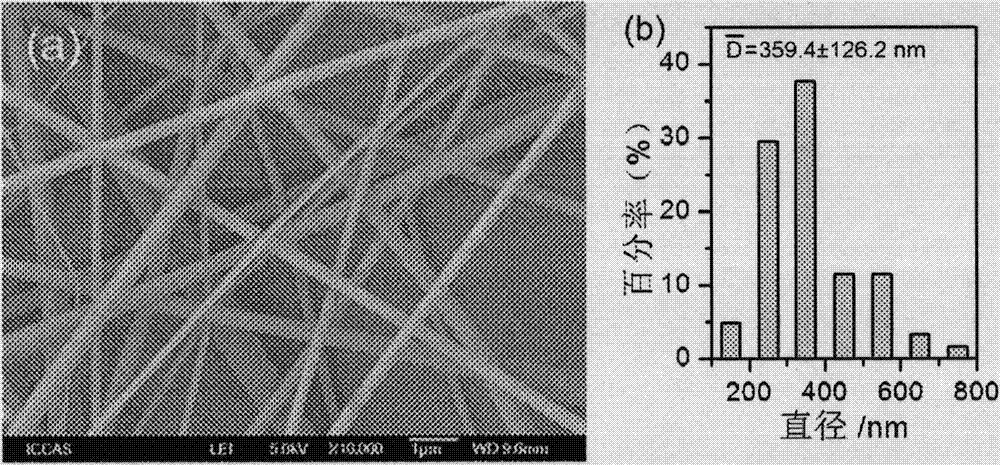

[0042] Example 1: Preparation of sodium hyaluronate / cellulose acetate core-shell nanofibers containing naproxen in liposomes and its in vitro drug release determination

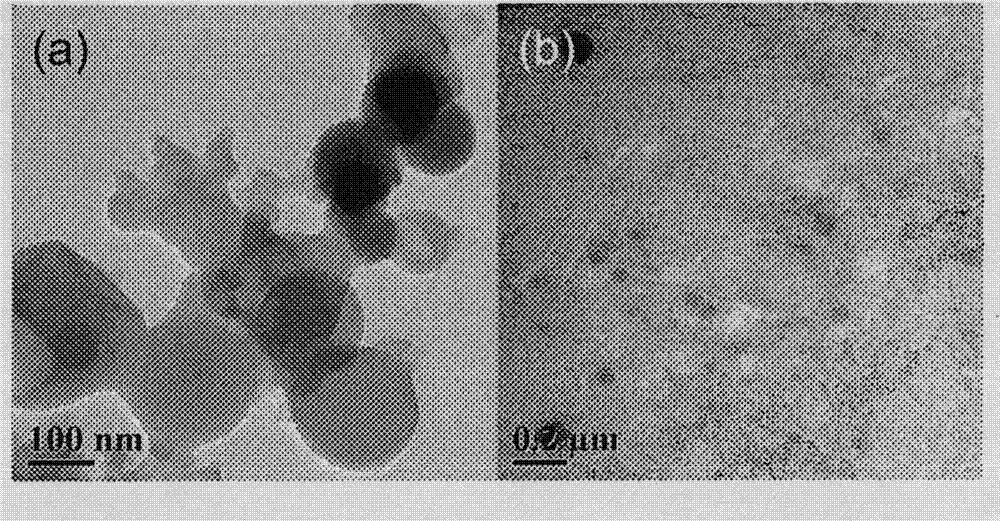

[0043] (1) Preparation of drug-loaded liposomes by lipid membrane hydration method: Lecithin (purchased from Aladdin, extracted from soybeans, purity> 98%) 160mg, cholesterol (purchased from Alfa Aesar, article number A11470, purity 95%) 20mg and naproxen (purchased from Alfa Aesar) 90mg were added to a 250mL round bottom flask, and then 5mL chloroform / methanol mixed solvent (v / v=2 / 1). After being fully dissolved, use a rotary evaporator to evaporate the solvent to a lipid film in a constant temperature water bath of about 30°C and a rotation speed of 60 rpm;

[0044] (2) Add 5 mL of ultrapure water and 0.5 g of glass beads to the above lipid membrane. The rotary evaporator was used again to rotate for 30 minutes in a constant temperature water bath at about 30° C. and a rotation speed of 60 rpm in a nitrogen env...

Embodiment 2

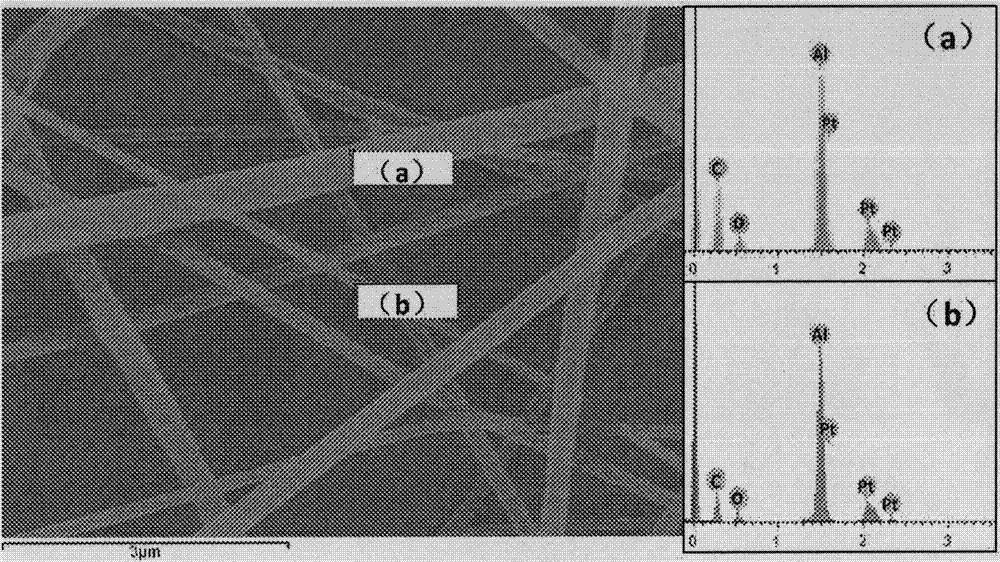

[0047] Example 2: Preparation of sodium hyaluronate / polyvinylpyrrolidone core-shell nanofibers containing rhodamine B in liposomes

[0048] (1) Preparation of fluorescent dye-loaded liposomes by lipid membrane hydration method: 80mg of lecithin (purchased from Alfa Aesar, extracted from soybeans, item number 36486), cholesterol (purchased from Alfa Aesar, item number A11470, purity 95%) Add 10mg to a 250mL round-bottom flask, and then add 5mL chloroform / methanol mixed solvent (v / v=2 / 1). After it is fully dissolved, use a rotary evaporator to evaporate the solvent in a constant temperature water bath at 30℃ and a rotation speed of 60rpm Get lipid film;

[0049] (2) Add 5 mL of a preformed Rhodamine B (purchased from Sigma Aldrich) aqueous solution with a concentration of 3 mg / mL to the above lipid film, and again use a rotary evaporator in a nitrogen environment at a constant temperature water bath of about 30°C and a rotation speed of 60 rpm Rotate for 30 min to obtain a suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com