Paclitaxel polymer micelle by using refined amphiphilic block copolymer as carrier

A technology of block copolymer and polymer glue, applied in the directions of drug combination, liquid delivery, powder delivery, etc., can solve the problems of the influence of the kinetic stability of the micelle system and the difficulty of controlling the tin content of the polymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

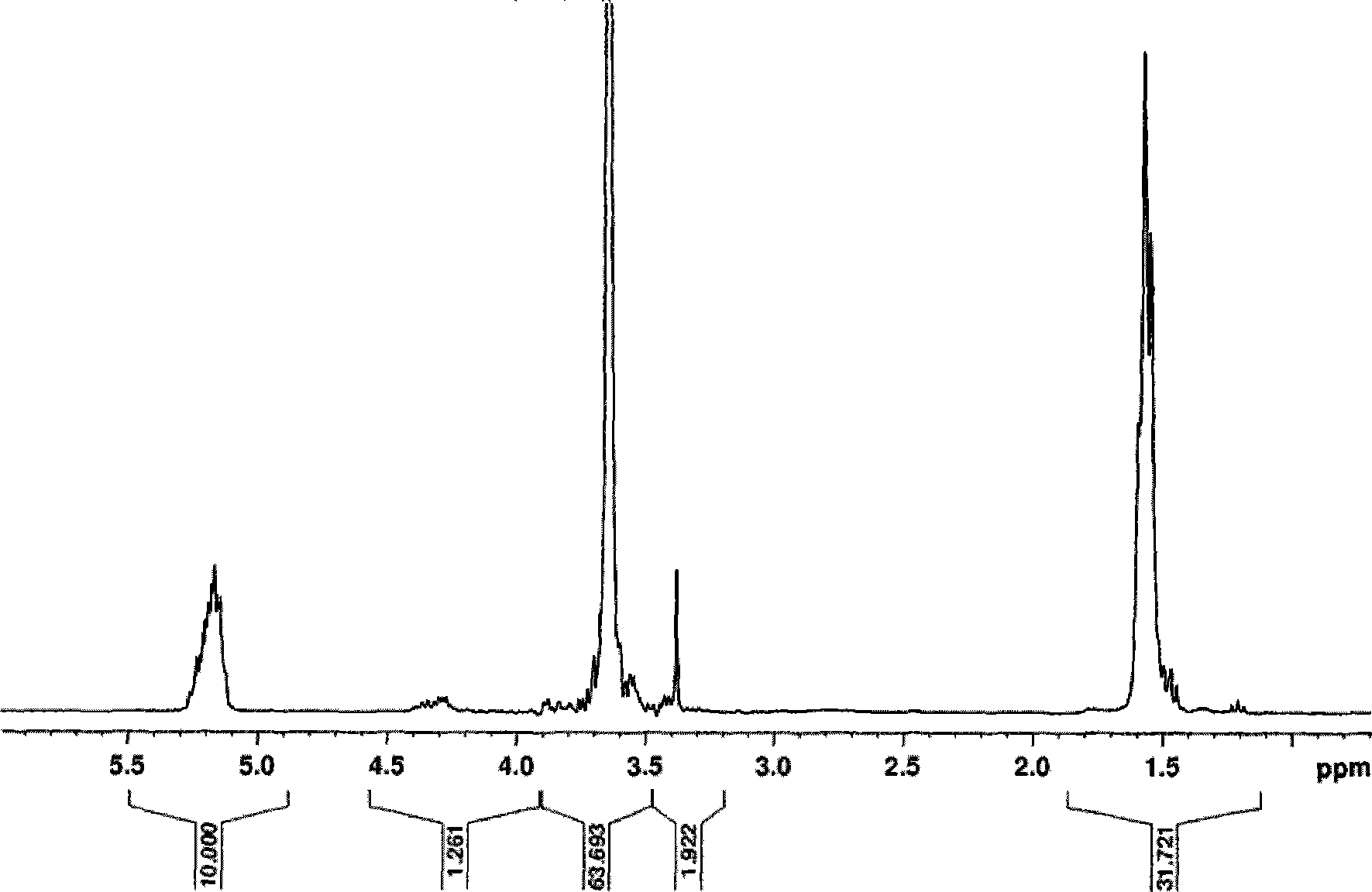

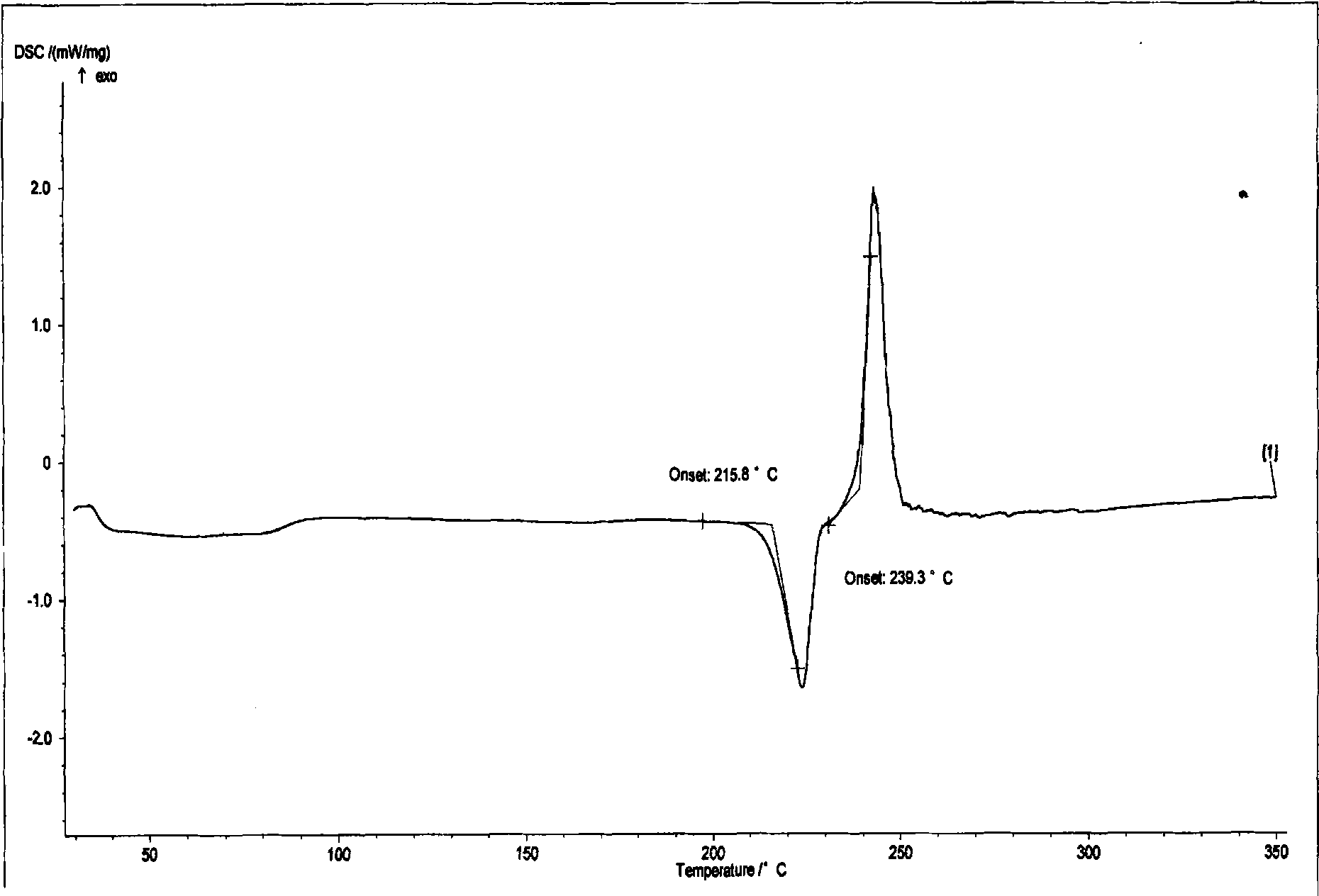

[0026] Synthesis and Molecular Weight Determination of Polyethylene Glycol Monomethyl Ether-Poly(D, L) Lactide Block Copolymer as the Carrier of Paclitaxel Polymer Micelles.

[0027] D, L-lactide: purchased from Shandong Daigang Biotechnology Co., Ltd., vacuum-dried in phosphorus pentoxide at room temperature for 24 hours before use; mPEG2000: purchased from Sigma-Aldrich, dried in vacuum with phosphorus pentoxide at room temperature before use 24 hours; stannous octoate: available from Sigma-Aldrich.

[0028] 1. Synthesis of polyethylene glycol monomethyl ether poly-polylactide block copolymer:

[0029] A polyethylene glycol monomethyl ether-poly(D, L) lactide block copolymer with a mass ratio of 50 / 50 was prepared by ring-opening polymerization. Weigh 5 g of polyethylene glycol monomethyl ether and 5 g of D, L-lactide, place them in a sealed reactor, raise the temperature to 120-140 ° C under nitrogen flow to melt the solid, add 50 mg of stannous octoate, and raise the temp...

Embodiment 2

[0038] This example is a comparison of tin content in polyethylene glycol monomethyl ether poly-polylactide block copolymer before and after refining (cation exchange resin treatment).

[0039] The tin content in the polymer was determined by inductively coupled plasma emission spectrometry (ICP-AES). Working conditions of inductively coupled plasma atomic emission spectrometry (ICP-AES) instrument: generator power is 1300W, argon gas purity is 99.999%, cooling gas flow rate is 15L / min, auxiliary device flow rate is 0.2L / min, atomizer flow rate is 0.80L / min, the lifting volume of the test solution is 1.5mL / min, the integration time is 2-10s, and the axial observation method is adopted. The analytical spectral lines of tin element are 189.927nm respectively. The sample digestion adopts the microwave digestion method: the heating power is 1000W, the temperature is raised to 200°C, and the heating time is 15min; the temperature is kept at 200°C, and the holding time is 20min. T...

Embodiment 3

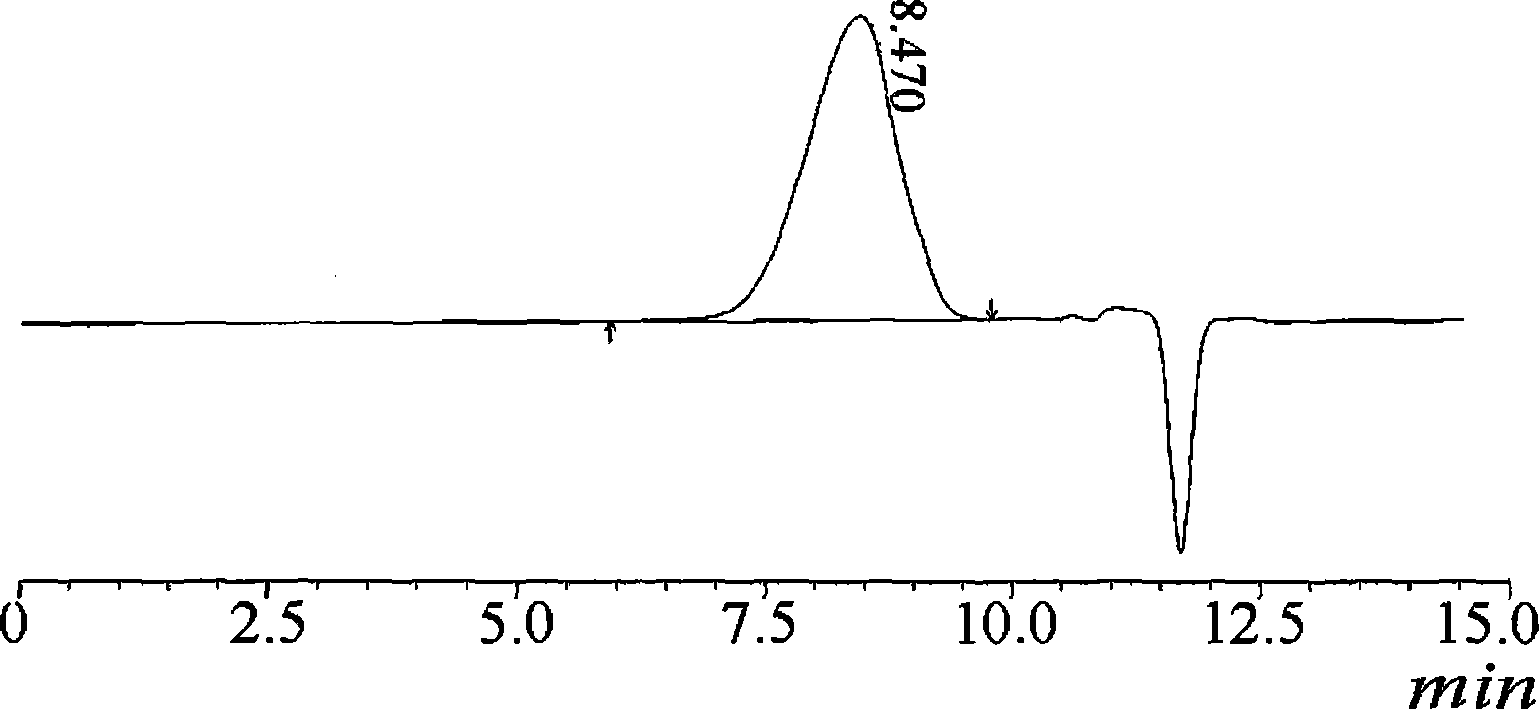

[0043] Preparation of paclitaxel-polyethylene glycol monomethyl ether-poly(D, L) lactide block copolymer micelles and study on particle size stability

[0044] 1. Preparation of paclitaxel polyethylene glycol monomethyl ether-poly(D, L) lactide block copolymer micelles

[0045] Put paclitaxel 300mg and paclitaxel polyethylene glycol monomethyl ether-poly(D, L) lactide block copolymer block copolymer (mass ratio 5:5) 1500mg in an eggplant-shaped bottle, add methanol 15ml to dissolve completely , heated in a water bath at 50°C and evaporated to dryness under reduced pressure, and was attached to the bottom of the bottle in the form of a transparent film. Add 30ml of water for injection, heat in a water bath at 50°C, and rotate the film to hydrate for 15 minutes to obtain light blue opalescent micelles. Filter with a 0.22 μm filter membrane, dispense 3ml into vials, and freeze-dry to obtain white loose needle-like powder.

[0046] 2. Comparison of particle size stability of mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com