Osmanthus phenylethanoid glycoside extract, and preparation method and application thereof

A technology of phenylethanol glycosides and total phenylethanol glycosides from osmanthus fragrans, which is applied in the field of phenylethanol glycoside extracts, can solve the problems of not paying attention to the stability of phenylethanol glycoside compounds, the extraction yield and the influence of the purity of the extract, and achieve good quality and composition Clear, wide-source effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

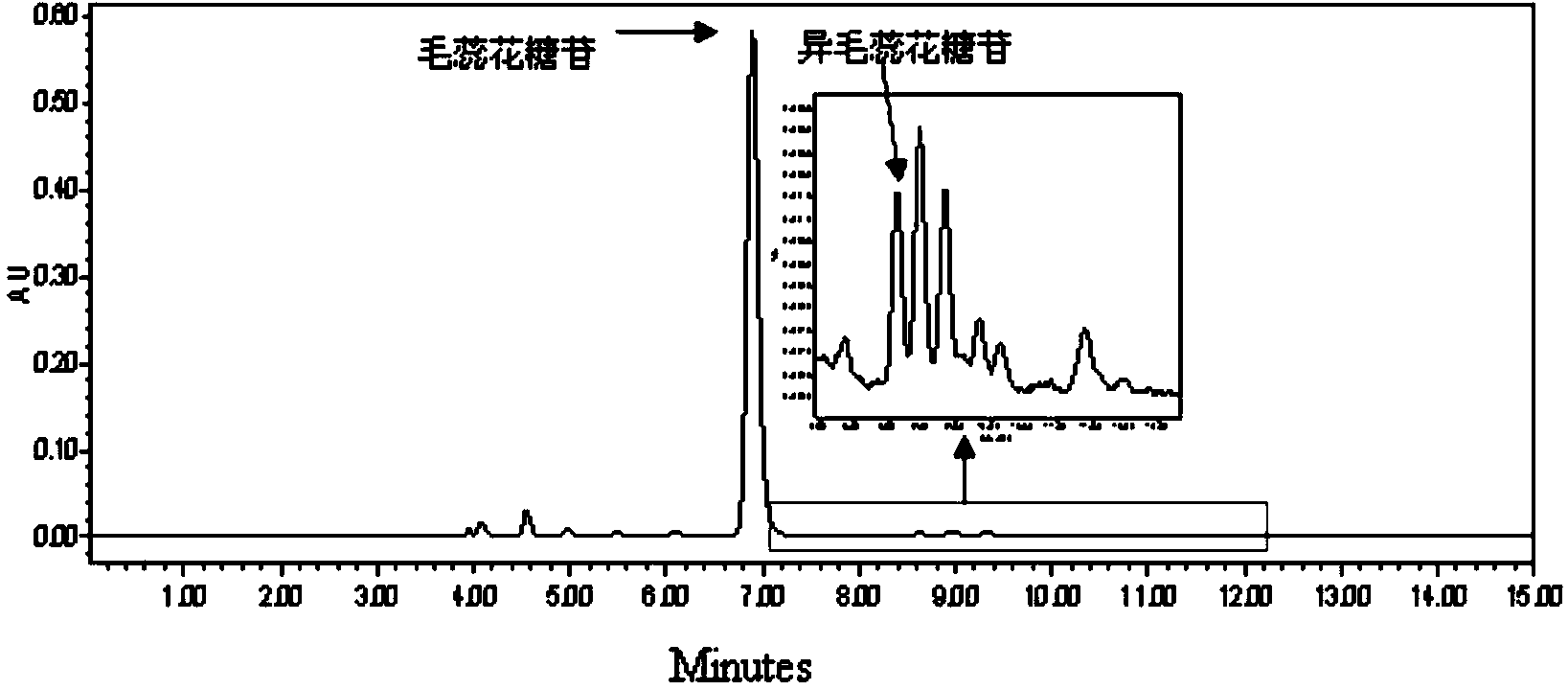

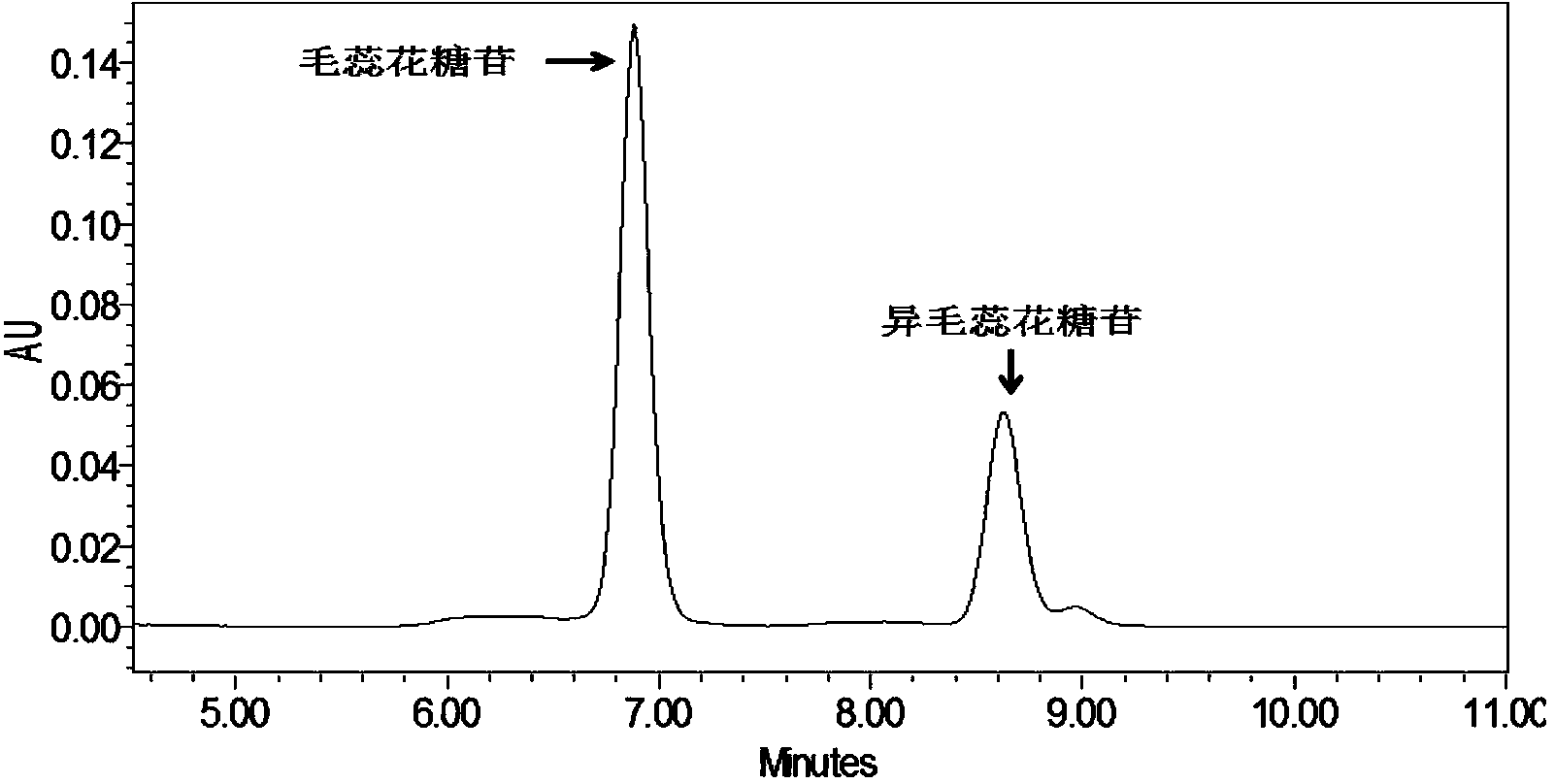

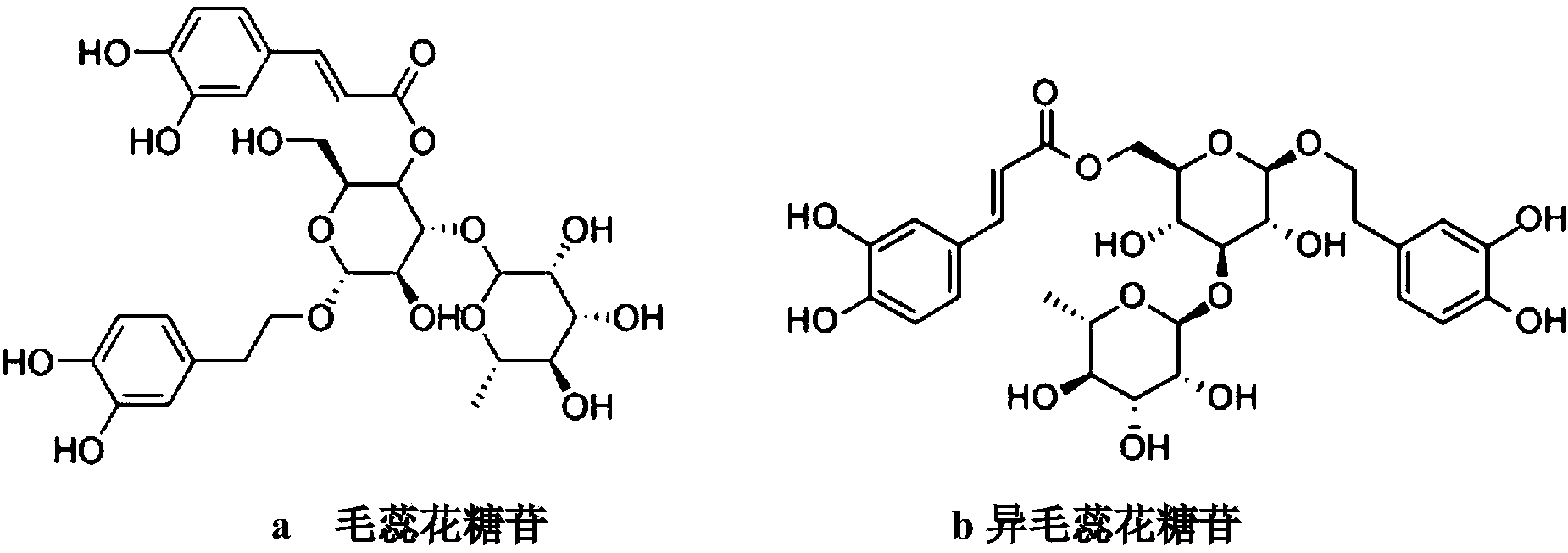

Method used

Image

Examples

Embodiment 1

[0068] Crush 1 kg of dried Jingui flowers (moisture content ≤ 10%, crushed to pass through a 20-mesh sieve), add 15L of 80% (volume %) ethanol aqueous solution, and then add 0.1% sodium erythorbate aqueous solution (that is, each 1 liter of sodium erythorbate aqueous solution contains 1g of sodium erythorbate) 2L, use 1mol / L formic acid aqueous solution to adjust the pH of the extraction solution to about 5; extract at a temperature of 50°C to 80°C for 2 hours, cool to room temperature, and filter to obtain the extract Liquid; Concentrate the extract directly under reduced pressure (at 0.010-0.100MPa, temperature 50-60°C), recover ethanol to obtain a concentrated solution (about 4L), then dilute with water until the pH of the diluted solution is about 5; The liquid is absorbed by the adsorption resin (the adsorption resin is HPD300, the dosage is 1L), and it is eluted with 2L of 30% (volume %) ethanol aqueous solution; ), after spray drying (inlet air temperature is 180-200°C,...

Embodiment 2

[0087] Crush 1 kg of dried osmanthus osmanthus (water content ≤ 10%, crushed to pass through a 20-mesh sieve), add 10 L of 90% (volume %) ethanol aqueous solution, and then add 0.2% ascorbic acid aqueous solution (that is, each liter of ascorbic acid aqueous solution containing 2g ascorbic acid) 2L, use 0.5mol / L acetic acid aqueous solution to adjust the pH of the extraction solution to about 4; extract at a temperature of 50°C to 80°C for 2 hours, cool to room temperature, and filter to obtain the extract; directly extract the extract Concentrate under reduced pressure (at 0.010-0.100MPa, temperature 50-60°C), recover ethanol, obtain a concentrated solution (about 1.5L), and then dilute with water until the pH of the diluted solution is about 4; absorb the diluted solution with an adsorption resin (The adsorption resin is HPD300, the dosage is 1L), and it is eluted with 2L of 30% (volume %) ethanol aqueous solution; After microwave drying (process parameters: microwave power ...

Embodiment 3

[0090]Crush 1 kg of dried Osmanthus osmanthus (water content ≤ 10%, crushed to pass through a 20-mesh sieve), add it to 10 L of 90% (volume %) ethanol solution, and then add 0.1% bamboo leaf antioxidant aqueous solution (that is, the Each liter of bamboo leaf antioxidant aqueous solution contains 1g of bamboo leaf antioxidant) 2L, using 1mol / L acetic acid aqueous solution to adjust the pH of the extraction solution to about 5; the extraction solution is obtained; the extraction solution is carried out at a temperature of 50°C to 80°C Leach for 2 hours, cool to room temperature, and filter to obtain the extract; directly concentrate the extract under reduced pressure (at 0.010-0.100MPa, temperature 50-60°C), recover ethanol, and obtain a concentrate (about 2.5L), Then dilute with water until the pH of the diluted liquid is about 4; absorb the diluted liquid with an adsorption resin (the adsorption resin is HPD300, the dosage is 1 L), and elute with 2 L of 30% (volume %) ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com