Honeycomb-type denitration catalyst with hierarchical pore structure and preparation method for honeycomb-type denitration catalyst

A denitration catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effects of less dosage, less active ingredient content, and increased porosity and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation of catalyst carrier is not the innovative point of the present invention, and those skilled in the art can buy required carrier on the market, and the present invention mainly uses V 2 o 5 -WO 3 / TiO 2 Catalyst is taken as an example to illustrate the preparation process of the present invention.

[0052] In the following examples, used PMMA microspheres, PS microspheres and polyethylene oxide are commercially available products, and the ball diameters of PMMA microspheres and PS microspheres are in the range of 30-200 mm, and the molecular weight of polyethylene oxide is at 1 × 10 5 -1×10 6 scope.

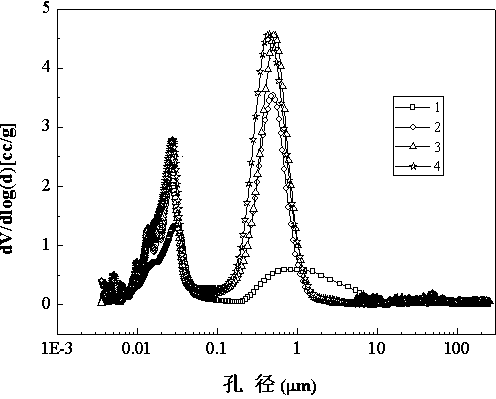

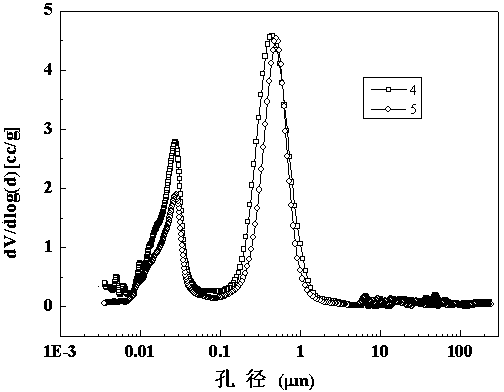

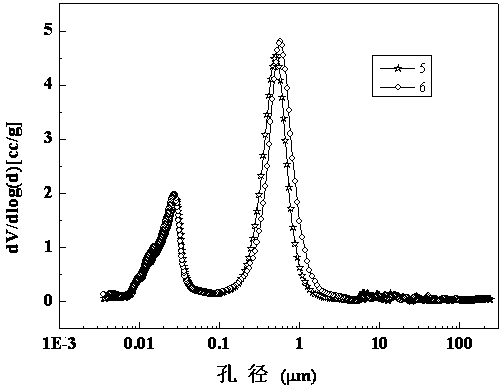

[0053] The catalysts obtained in the examples were subjected to mechanical strength tests, porosity, pore size distribution and pore volume tests, and SEM characterization and denitrification experiments were performed on the catalysts.

[0054] The mechanical strength test was carried out on an Instron-5569 electronic universal testing machine with a t...

Embodiment 1

[0063] One mixing: add 16.67 g titanium tungsten powder, 3.33 g titanium tungsten silicon powder, 1.4 g (according to 7 wt.% of the total amount of titanium tungsten powder and titanium tungsten silicon powder, that is catalyst carrier WO 3 / TiO 2 -SiO 2 Add 7wt% of the mass of the mass, the same below) chopped glass fiber, 0.6 g (according to 3 wt.% of the total amount of titanium tungsten powder and titanium tungsten silicon powder, that is, the catalyst carrier WO 3 / TiO 2 -SiO 2 Add 3wt% of the mass of the mass, the same below) methyl cellulose is added into the mixer, the mixing time is 2-3 h, and the mixing is completed.

[0064] Secondary mixing: take out the material mixed in the first time, add 1.0 g lactic acid (according to 5 wt.% of the total amount of titanium tungsten powder and titanium tungsten silicon powder, that is, the catalyst carrier WO 3 / TiO 2 -SiO 2 Add 5wt% of the mass of the mass, the same below), 1.0 g (according to 5 wt.% of the total amount ...

Embodiment 2

[0071]The catalyst was prepared by the same method as in Example 1, except that the following method was used for one mixing: 16.67 g titanium tungsten powder, 3.33 g titanium tungsten silicon powder, 1.4 g (7 wt.%) chopped glass fiber, 0.6 g (3 wt.%) methylcellulose, 1.0 g (according to 5 wt.% of the total amount of titanium tungsten powder and titanium tungsten silicon powder added, that is, the catalyst carrier WO 3 / TiO 2 -SiO 2 Add 5wt% of the mass of the mass, the same below) Polyethylene oxide is added into the mixer, the mixing time is 2-3 h, and the mixing is completed.

[0072] The resulting product has moderate viscosity, is easy to extrude, and has a smooth surface without cracking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com