Micro/nano hierarchical titanium dioxide microspheres as well as preparation method and application thereof

A titanium dioxide, hierarchical structure technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of complex synthesis steps, affecting production efficiency, long reaction time, etc., to achieve shortened reaction time, good classification Simple structure and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

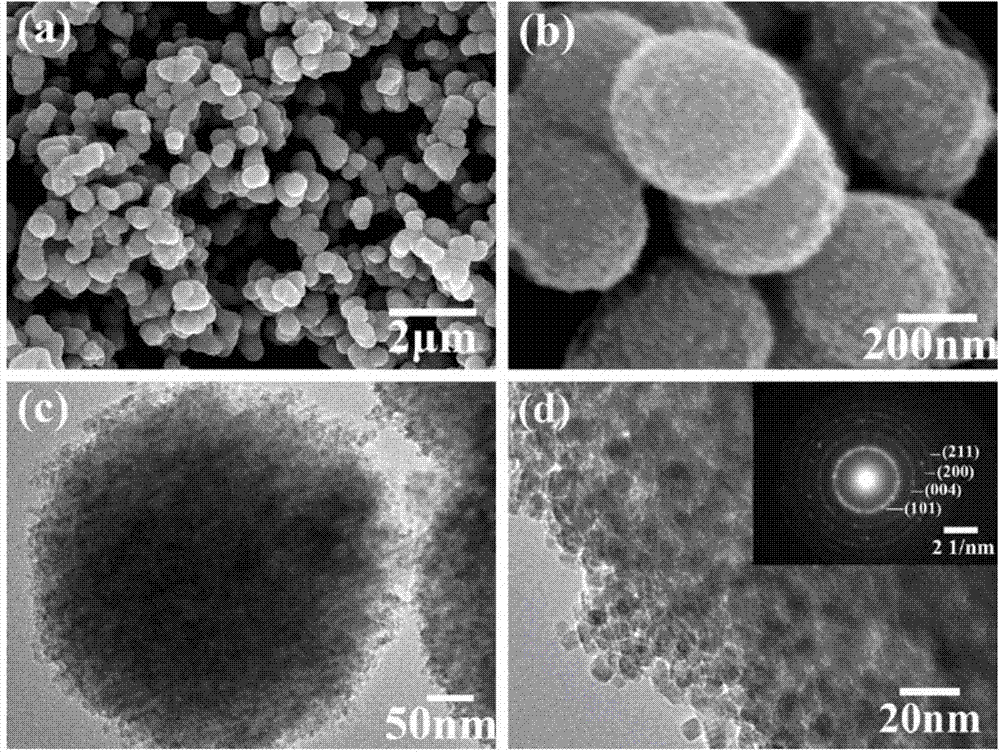

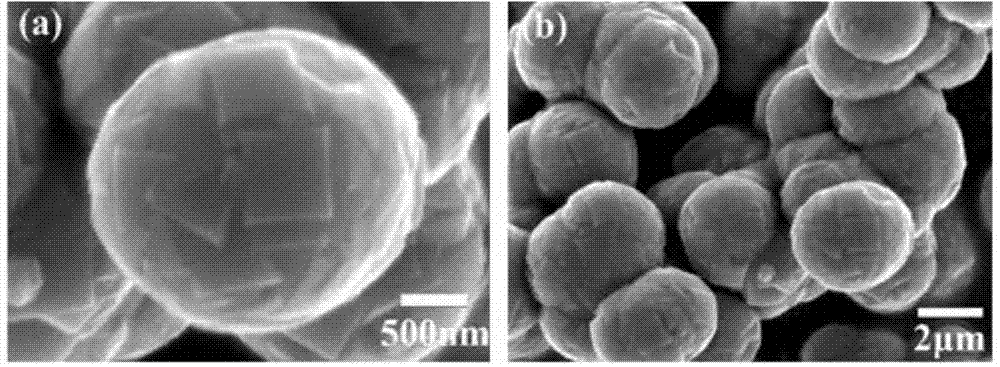

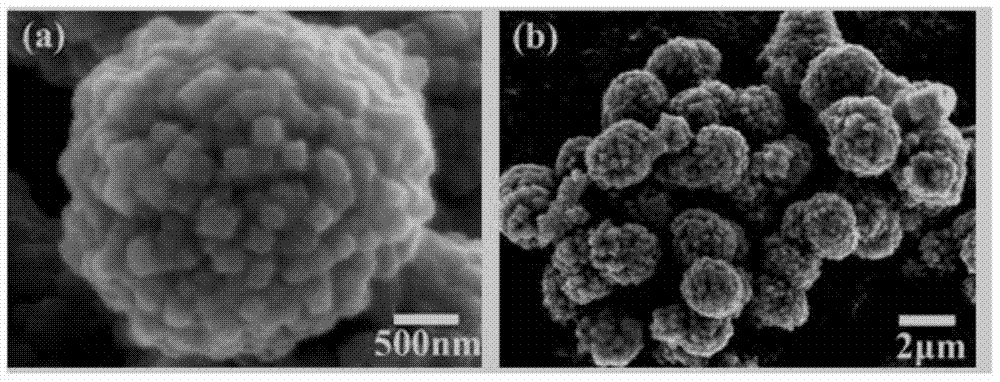

Embodiment 1

[0032] The synthesis of titanium dioxide microspheres with micro / nano hierarchical structure composed of nanoparticles (referred to as No. 1 microspheres) is completed in the following steps: first, titanium sulfate and urea are put into polytetrafluoroethylene at a molar ratio of 1:2-8 In the inner tank of the autoclave; then add deionized water until the filling degree of the inner tank is about 30-60%, and stir for 2-4 hours to obtain a uniform solution. Then put the autoclave into a microwave heating system (QWAVE 4000, 2450 MHz, maximum power 1200 W, Questron Technologies Corp), the reaction temperature is 180°C, and the holding time is 5-30min; after the reaction is completed, the autoclave is naturally cooled, and the reaction The product is repeatedly washed with deionized water and absolute ethanol until the aqueous solution is neutral, and finally the product is dried in an oven at 70°C for 2-10 hours, and the final product is titanium dioxide microspheres with a ...

Embodiment 2

[0036] Taking No.1 microsphere as an example, the research on the water treatment application of the synthetic product was carried out. As we all know, dyes and other organic pollutants exist in large quantities in industrial wastewater discharge, so the adsorption and degradation of dyes and other pollutants has very important environmental protection significance. In this experiment, the photocatalytic degradation of organic dyes was tested with No. 1 microspheres. Photocatalytic degradation of organic dyes. Specific steps are as follows:

[0037] First, choose methyl orange as the simulated organic waste water, weigh 40mg of microspheres, add it into 80ml (10-5M) methyl orange solution under dark conditions, and stir for 30min to achieve the absorption of microspheres and methyl orange solution balance. Then the mixed solution is placed under a 300W high-pressure mercury lamp for irradiation under strong stirring conditions. During the irradiation process, the mercury la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com