Electrochemical coupling upflow anaerobic bioreactor and application method

An anaerobic biology and reaction device technology, applied in the field of water treatment, can solve the problems of accelerated reduction and degradation of chlorinated compounds, low utilization efficiency, difficult biodegradation, etc., and achieve the effect of good working performance, reasonable structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

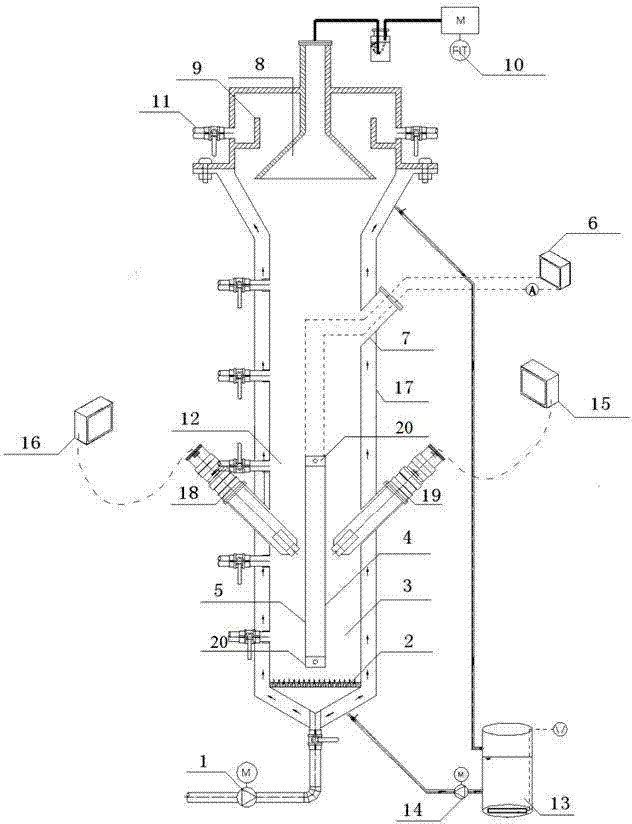

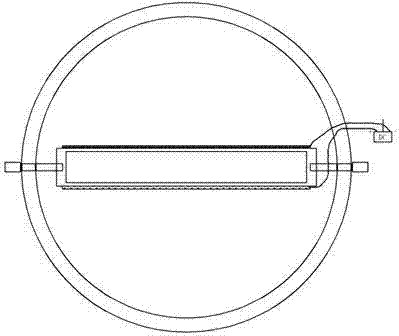

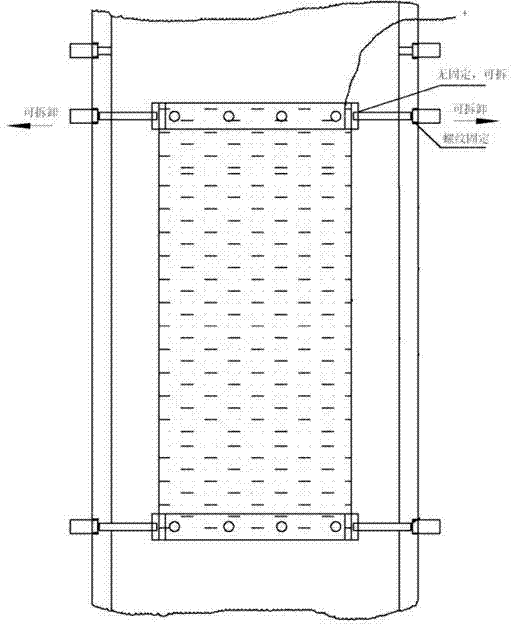

[0031] figure 1 A schematic structural diagram of a novel electrochemically coupled anaerobic reaction device is shown. The device mainly includes a cylindrical upflow anaerobic bioreactor cylinder 12 (anaerobic reactor), in which a water distribution plate 2, a sludge bed 3 and a three-phase separator 8 are sequentially arranged from bottom to top , a pair of bioelectrodes are installed at the bottom of the sludge bed 3 of the anaerobic reactor through a fixture. The shell of the anaerobic reactor is made of organic glass, with an inner diameter of 9cm, a height of 60cm, a total volume of 4.85L, and an effective volume of 4.05L. The bio-electrode pair is composed of a bio-cathode 4 and a bio-anode 5, which are fixed on the anaerobic reactor cylinder through a detachable electrode fixing device, and the corrosion-resistant titanium wire connecting the bio-cathode 4 and the bio-anode 5 passes through the anaerobic reactor cylinder The set wire closed channel 7 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com