Photo-catalysis method adopting ultrasonic atomizing process to enhance water pollution treatment effect

A sewage treatment, ultrasonic atomization technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc. High photocatalyst utilization rate and low photocatalyst utilization rate to achieve the effect of improving photocatalyst utilization rate, improving light energy utilization rate, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

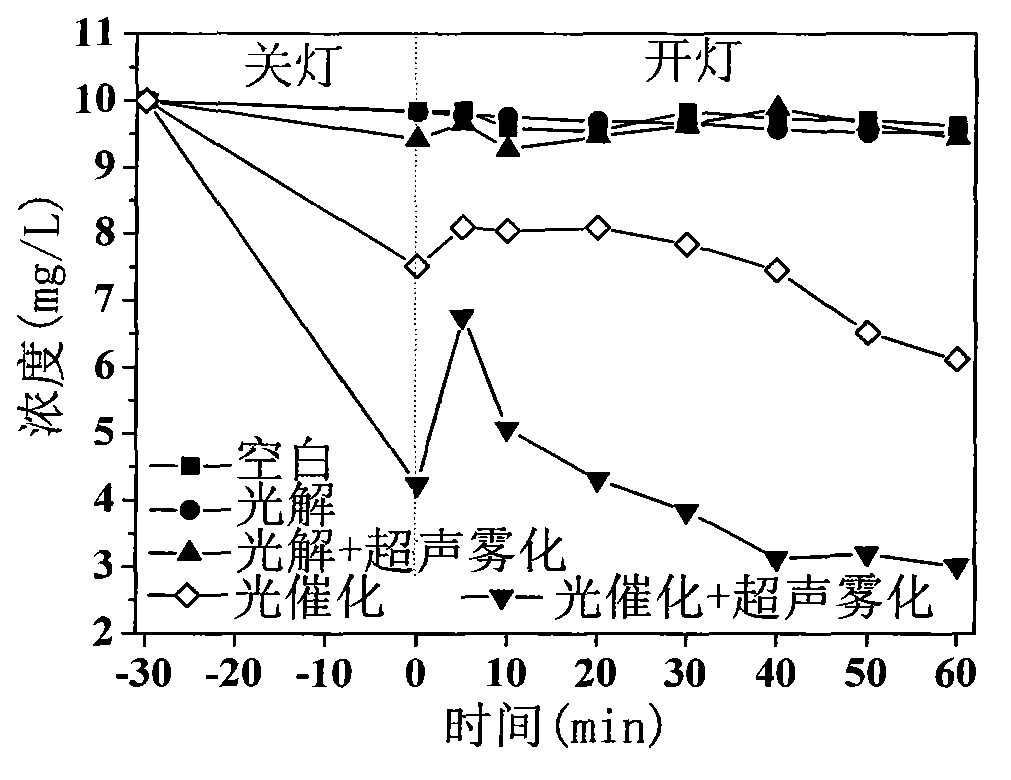

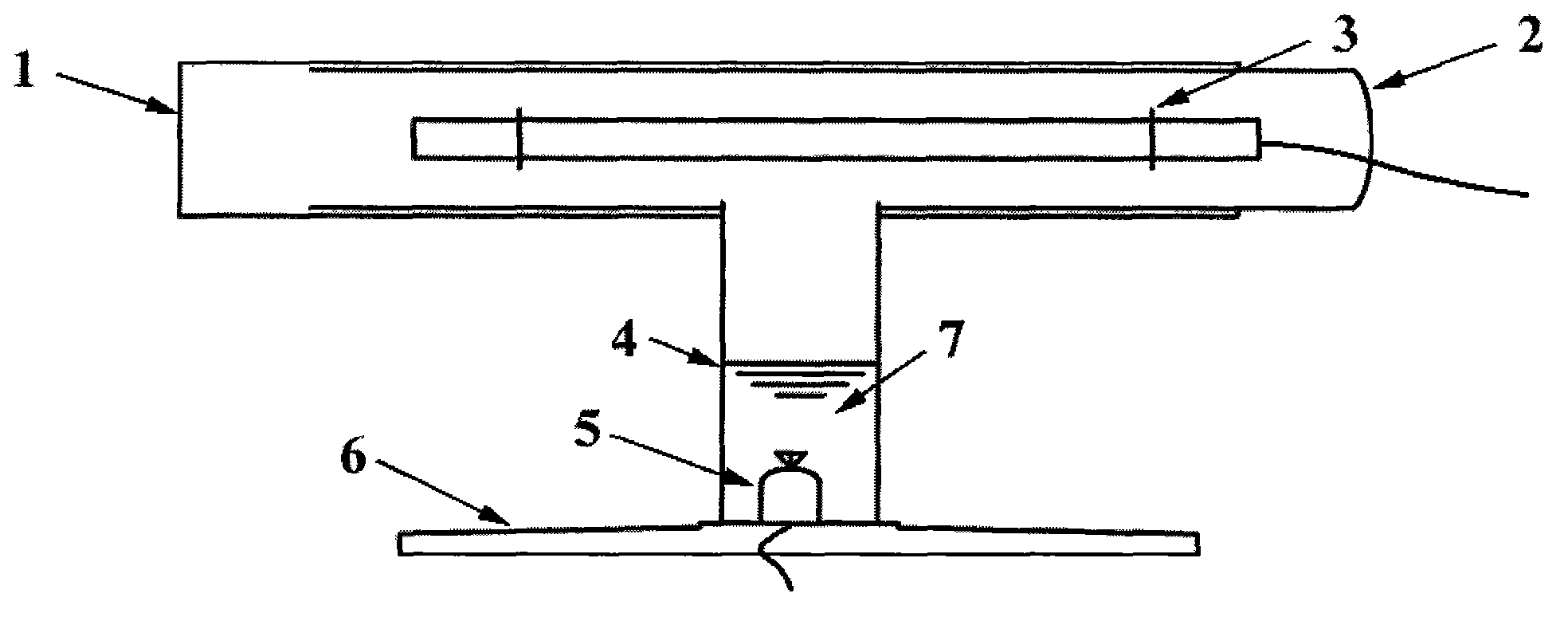

Embodiment 1

[0024] Weigh powder nano TiO 2 Photocatalyst (30 nanometers of particle size) 0.25 gram, is dispersed in the beaker that weighs 100 milliliters containing pentachlorophenol concentration and is the simulated sewage of 10mg / L. The beaker was placed in an ultrasonic cleaner for ultrasonic dispersion for 30 minutes to destroy nanoaggregates. After the photocatalyst is fully mixed with the simulated sewage, it is poured into an atomization chamber with a volume of 150 ml, and the liquid level is 2.5 cm higher than the head of the ultrasonic transducer. Install the inner and outer chambers of the photoreactor with ultraviolet light source (UV-500, Beijing Tianmai Henghui Light Source Electric Co., Ltd.) on the top of the spray chamber, and the ultrasonic transducer (MU-360, Foshan Lifengda Machinery Equipment Co., Ltd.) Company) power on, the mist formed by the atomized droplets gradually rises, and when the height of the mist contacts the lower interface of the ultraviolet lamp, ...

Embodiment 2

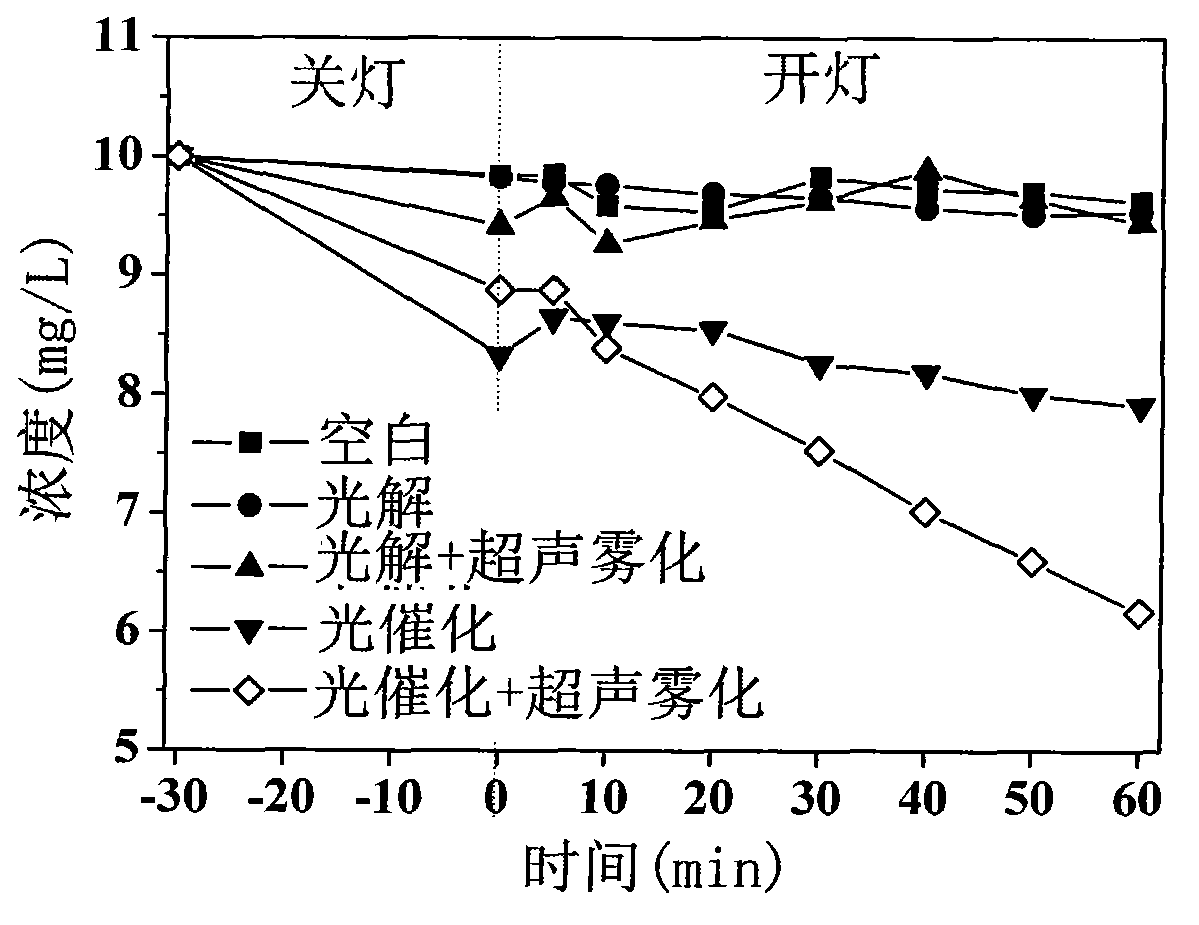

[0027] Weigh powder nano TiO 2 0.1 g of photocatalyst (25 nanometers in particle size) was dispersed in a beaker weighing 100 ml of simulated sewage containing bisphenol A at a concentration of 10 mg / L. After 30 minutes of ultrasonic dispersion, pour it into the atomization chamber, and the liquid level is 3.2 cm higher than the head of the ultrasonic transducer. After atomization, the reaction was stopped after 60 minutes of ultraviolet light irradiation. Timing sampling analysis. All the other specific operations are the same as in Example 1.

[0028] Under the effect of ultrasonic atomization, the photocatalytic degradation rate of bisphenol A can be increased from 19.2% to 41.7% in 60 minutes (such as figure 2 shown).

Embodiment 3

[0030] Weigh powdered nano-Bi 2 o 3 Photocatalyst (120 nanometers of particle size) 0.35 gram, is dispersed in the beaker that weighs 100 milliliters containing pentachlorophenol concentration and is the simulated sewage of 10mg / L. After 30 minutes of ultrasonic dispersion, pour it into the atomization chamber, and the liquid level is 4.0 cm higher than the head of the ultrasonic transducer. After atomization, the xenon lamp was irradiated for 60 minutes to stop the reaction. Timing sampling analysis. All the other specific operations are the same as in Example 1.

[0031] Under the action of ultrasonic atomization, the photocatalytic degradation rate of pentachlorophenol can be increased from 14.9% to 66.8% within 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com