Special casting material for 12000D/T kilneye

A castable and kiln mouth technology, which is applied in the field of high-temperature materials for building materials, can solve the problems of low-cement castables, easy peeling, non-wear resistance, etc., and achieve the goals of improving thermal shock resistance, improving non-wear resistance, and reducing internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

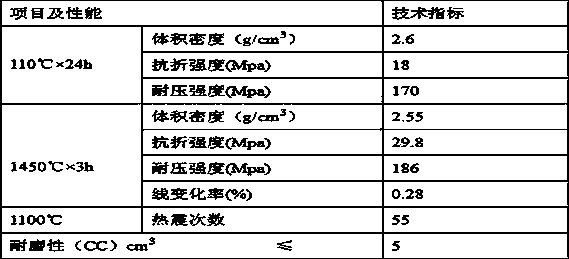

Image

Examples

Embodiment 1

[0049] A special castable for 12000D / T kiln mouth, the weight percentage of its components is:

[0050] Mullite 25%

[0051] Sillimanite 20%

[0052] Tabular alumina 25%

[0053] Strontium titanate powder 8%

[0054] Zirconia powder 5%

[0055] Zinc aluminum spinel powder 1%

[0057] Alumina fine powder 15%

[0058] Pure calcium aluminate cement 6%

[0059] Polylactic acid fiber 0.2%

[0060] Sodium hexametaphosphate is an additive, and the addition amount accounts for 0.1% of the total weight of the above components.

Embodiment 2

[0062] A special castable for 12000D / T kiln mouth, the weight percentage of its components is:

[0063] Mullite 25%

[0064] Sillimanite 20%

[0065] Tabular alumina 30%

[0066] Strontium titanate powder 8%

[0067] Zirconia powder 8%

[0068] Zinc aluminum spinel powder 1.5%

[0070] Alumina fine powder 5%

[0071] Pure calcium aluminate cement 3%

[0072] Polylactic acid fiber 0.2%

[0073] Sodium hexametaphosphate is an additive, and the addition amount accounts for 0.1% of the total weight of the above components.

Embodiment 3

[0075] A special castable for 12000D / T kiln mouth, the weight percentage of its components is:

[0076] Mullite 20%

[0077] Sillimanite 20%

[0078] Tabular alumina 28%

[0079] Strontium titanate powder 10%

[0080] Zirconia powder 8%

[0081] ZnAl spinel powder 3%

[0083] Alumina fine powder 5%

[0084] Pure calcium aluminate cement 3.5%

[0085] Polylactic acid fiber 0.2%

[0086] Sodium hexametaphosphate is an additive, and the addition amount accounts for 0.1% of the total weight of the above components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com