Method for preparing CuInxGaySez prefabricated layer by electrochemical deposition

A copper indium gallium selenide and prefabricated layer technology, applied in the field of solar cells, can solve problems affecting the formation of copper indium gallium selenide crystals, four elements cannot be co-deposited simultaneously, and small voids in the copper indium gallium selenide layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

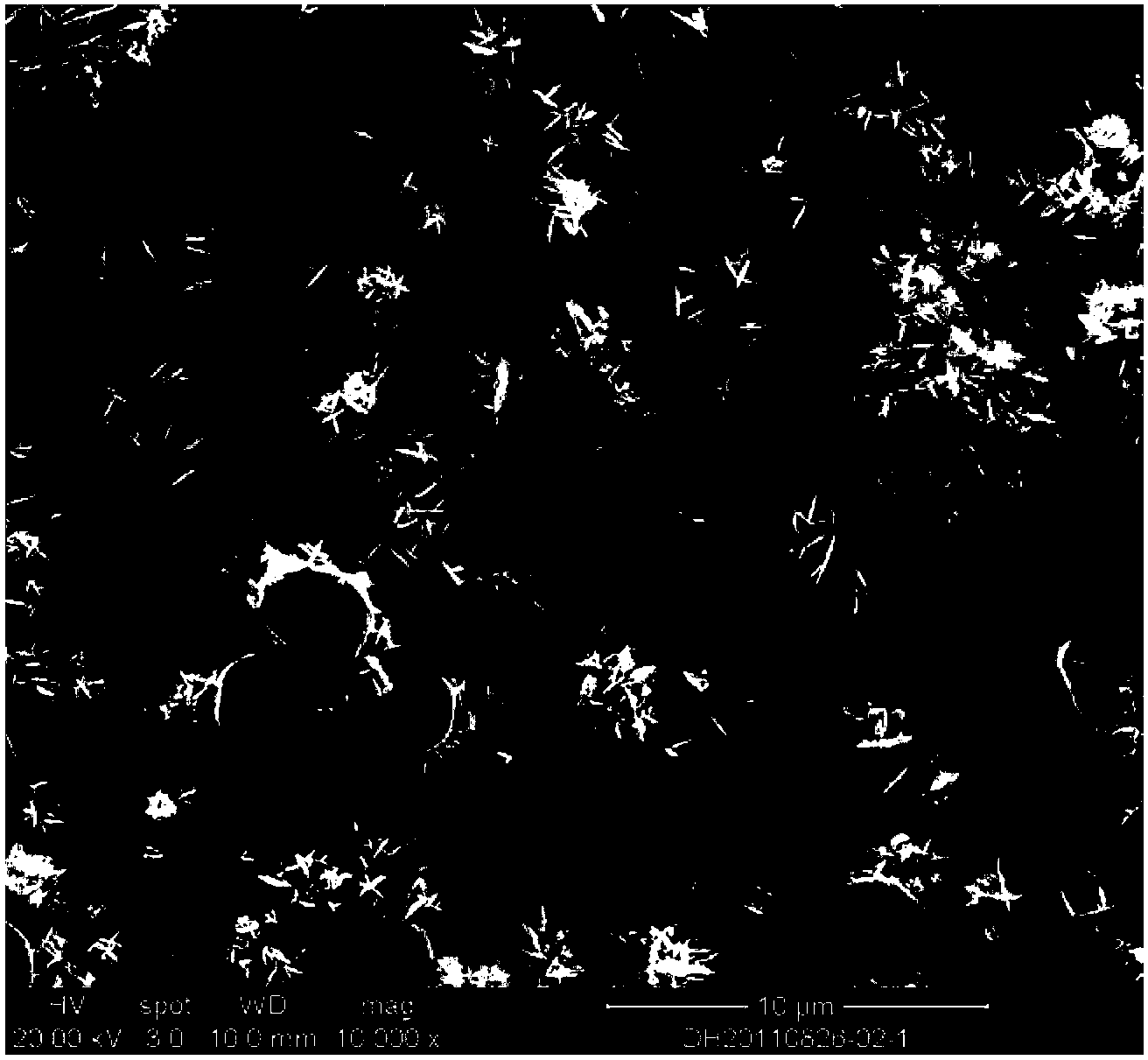

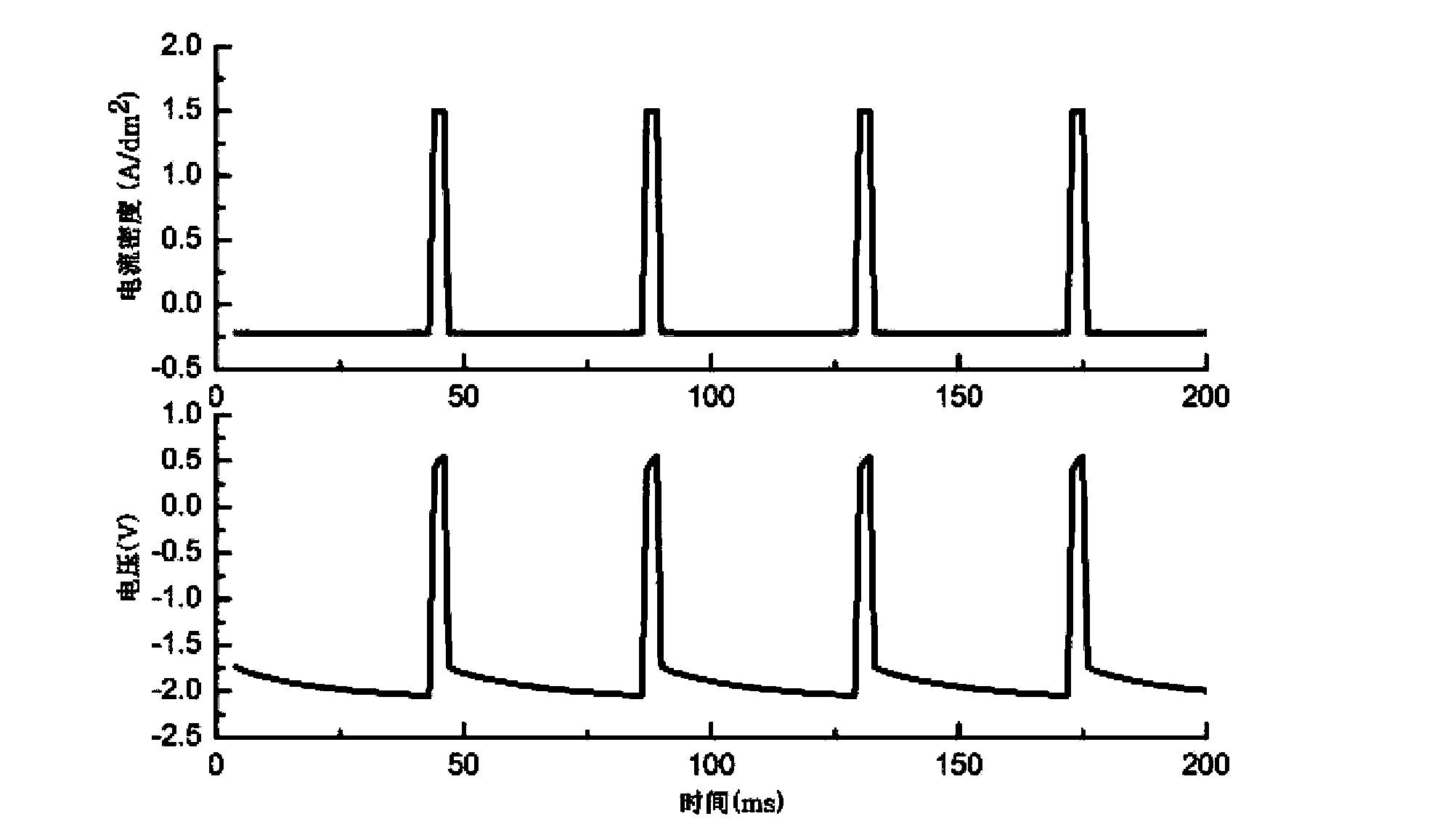

[0052] The method for preparing the copper indium gallium selenide prefabricated layer by electrochemical deposition listed in this embodiment includes electrodepositing the copper indium gallium selenide prefabricated layer on the cathode substrate by using a current pulse in an electrodeposition solution. The cathode substrate is soda-lime glass covered with a conductive molybdenum layer formed by vacuum sputtering. Wherein, the current pulse includes a forward pulse period in which the current and voltage are both negative on the deposition surface and a reverse pulse period in which the current and voltage are both positive on the deposition surface. Pulse current density and corresponding voltage change see figure 2 , pulse current density and working time are shown in Table 1.

[0053] In this embodiment, the electrodeposition solution is an ionic liquid system, the ionic liquid system is composed of urea and choline chloride, and the weight ratio of choline chloride t...

Embodiment 2

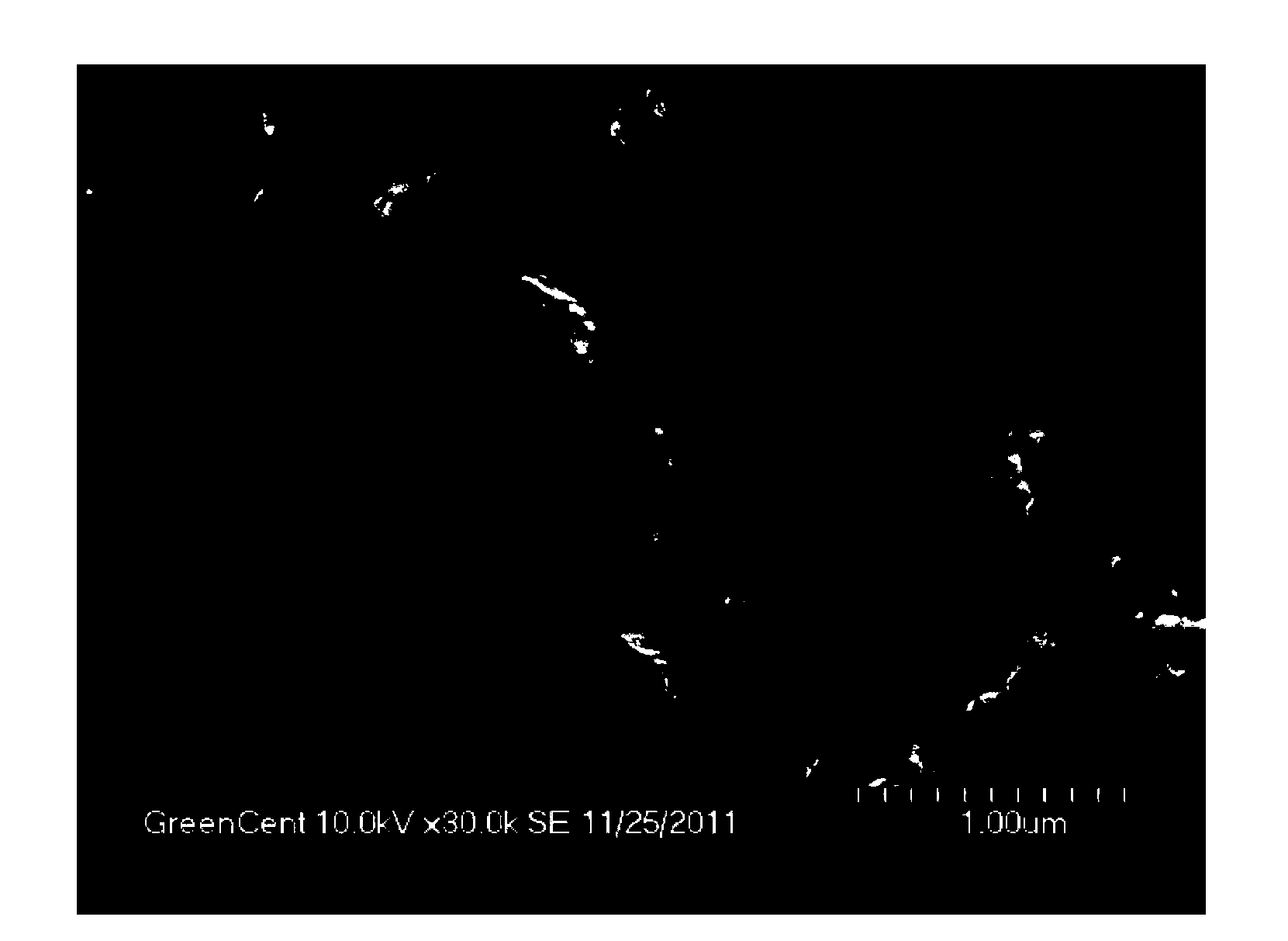

[0056] The method for preparing the copper indium gallium selenide prefabricated layer by electrochemical deposition in this embodiment includes electrodepositing the copper indium gallium selenide prefabricated layer on the cathode substrate by using voltage pulses in an electrodeposition solution. The cathode substrate is a glass substrate plated with Mo and Cu. Wherein, the voltage pulse includes a forward pulse period in which the current and voltage are both negative on the deposition surface and a reverse pulse period in which the current and voltage are both positive on the deposition surface. The pulse voltage and the corresponding current density change are shown in Figure 4 , see Table 1 for the voltage and working time of the reverse pulse wave.

[0057] In this embodiment, the electrodeposition solution is an ionic liquid system. The ionic liquid system is composed of urea and choline chloride. The weight ratio of choline chloride to urea is 1:1. In the ionic liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com