Lithium ion battery cathode additive and preparation method thereof, lithium ion battery cathode piece and lithium ion battery

A lithium-ion battery and additive technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, batteries, etc., can solve problems such as harsh process conditions, impact on performance, and reduced initial capacity of lithium-ion batteries, and achieve easy industrial production and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

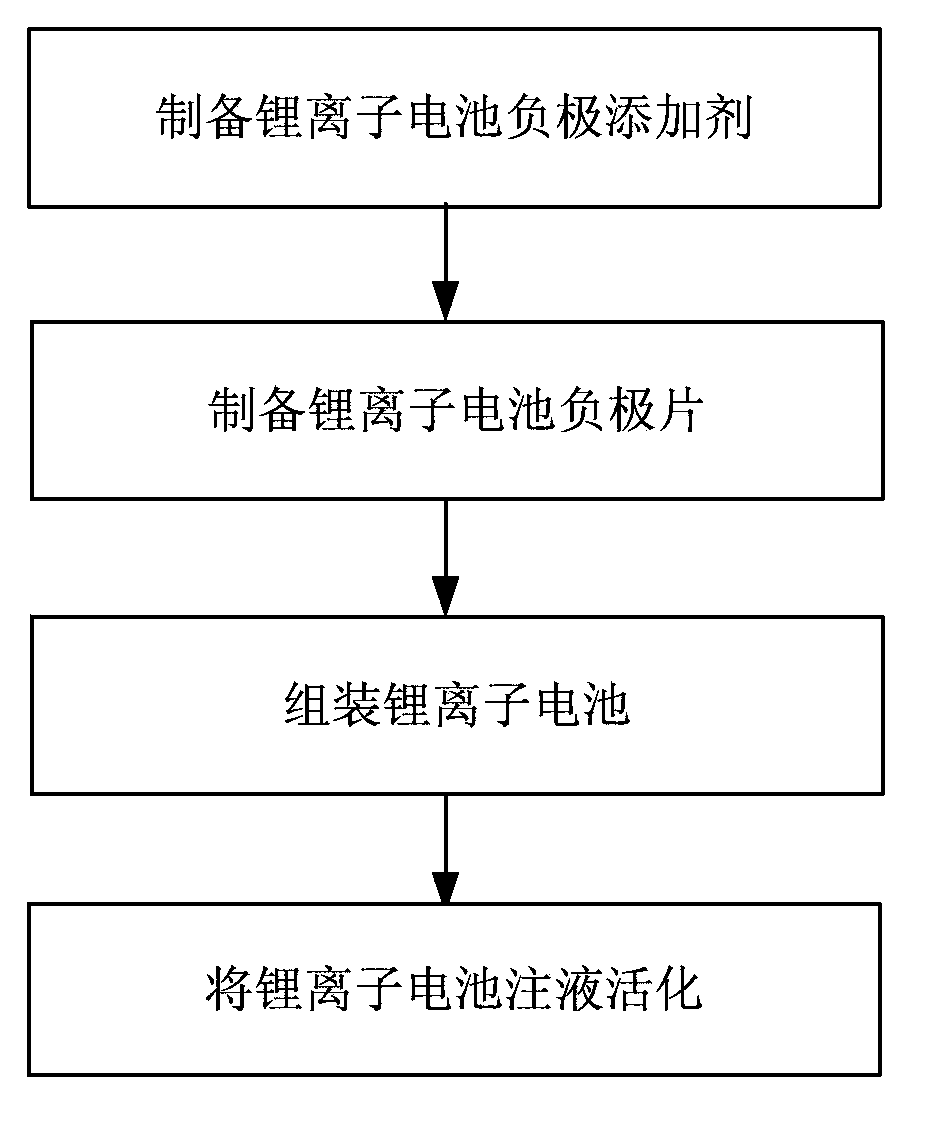

Method used

Image

Examples

preparation example Construction

[0042] In a second aspect, an embodiment of the present invention provides a method for preparing a negative electrode additive for a lithium ion battery, comprising the following steps: dissolving the polymer in a carbonate solvent to form a polymer solution, adding elemental lithium powder into the polymer solution, After stirring evenly, filter, take the filter residue, and spray dry the filter residue at a temperature of 50-80°C under the protection of an inert gas to obtain a lithium-ion battery negative electrode additive. The lithium-ion battery negative electrode additive is composed of elemental lithium powder and coated in The core-shell coating structure formed by the polymer on the surface of the elemental lithium powder, the polymer cannot be mixed with N,N-dimethylformamide, N,N-dimethylacetamide, N-2-methylpyrrolidone , THF, acetone and methanol.

[0043] The polymer can be dissolved in a carbonate solvent, and the carbonate solvent is selected from one or more ...

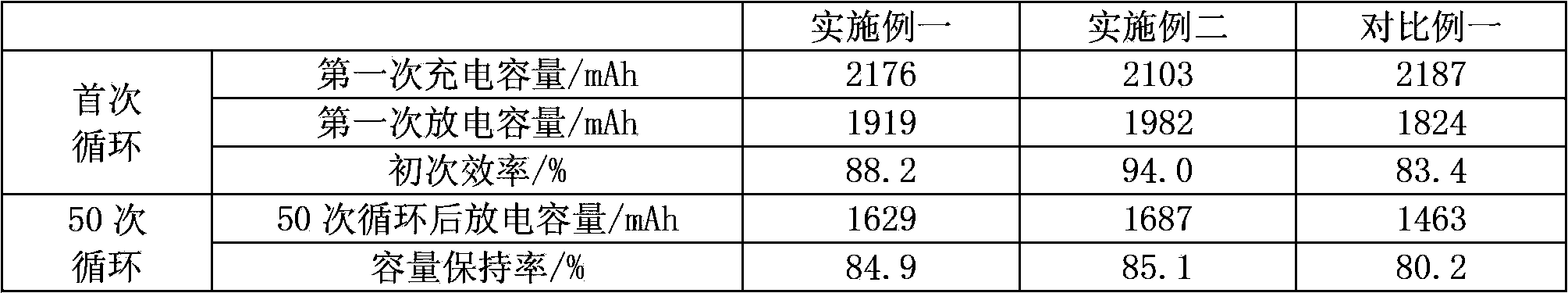

Embodiment 1

[0060] A preparation method of lithium ion battery negative electrode additive, comprises the following steps:

[0061] 25 grams of polypropylene carbonate with a weight-average molecular weight of 50,000 are dissolved in 200 grams of ethyl methyl carbonate (EMC) to form a polymer solution, stirred at a low speed for 15 minutes, 10 g of elemental lithium powder is dropped into the polymer solution, and stirred for 30 Minutes, filter, take the filter residue, wash it with deionized water, and then spray dry the filter residue at 80°C under the protection of argon at 70°C to prepare the negative electrode additive for lithium ion batteries.

[0062] The lithium ion battery negative electrode additive is a core-shell coating structure formed by elemental lithium powder and a polymer coated on the surface of the elemental lithium powder.

[0063] Preparation of Lithium-ion Battery Negative Electrode

[0064] Add 25 grams of polyvinylidene fluoride (PVDF) in 500 grams of N-2-methy...

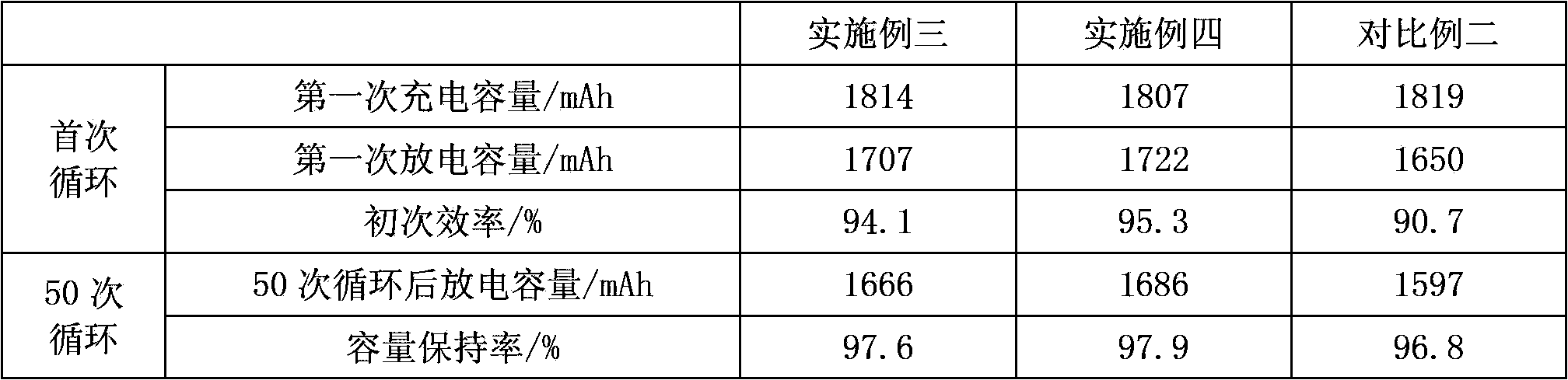

Embodiment 2

[0070] A preparation method of lithium ion battery negative electrode additive, comprises the following steps:

[0071]Dissolve 25 grams of polyethylene oxide with a weight average molecular weight of 50,000 in 200 grams of dimethyl carbonate (DMC) to form a polymer solution, stir at a low speed for 15 minutes, put 10 g of elemental lithium powder into the polymer solution, and stir After 30 minutes, filter, take the filter residue, wash it with deionized water flow, and then spray dry the filter residue at a temperature of 70°C under the protection of argon at 60°C to prepare a lithium ion battery negative electrode additive.

[0072] The lithium ion battery negative electrode additive is a core-shell coating structure formed by elemental lithium powder and a polymer coated on the surface of the elemental lithium powder.

[0073] Preparation of Lithium-ion Battery Negative Electrode

[0074] Add 25 grams of polyvinylidene fluoride (PVDF) in 500 grams of N-2-methylpyrrolidone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com