Antifouling paint for coating bottom of steel ship and preventing cracking

An anti-fouling paint and anti-cracking technology, applied in the field of coatings, can solve the problems of brittleness and unfriendly environment of anti-fouling paint, and achieve the effect of convenient painting and construction, not easy to fall off, and good crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

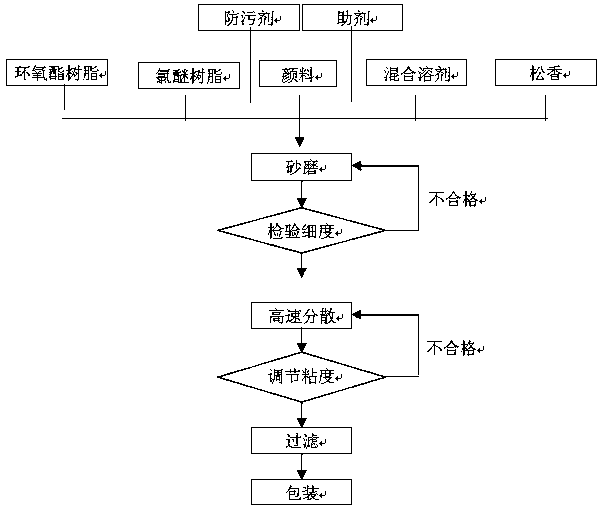

Method used

Image

Examples

example 1

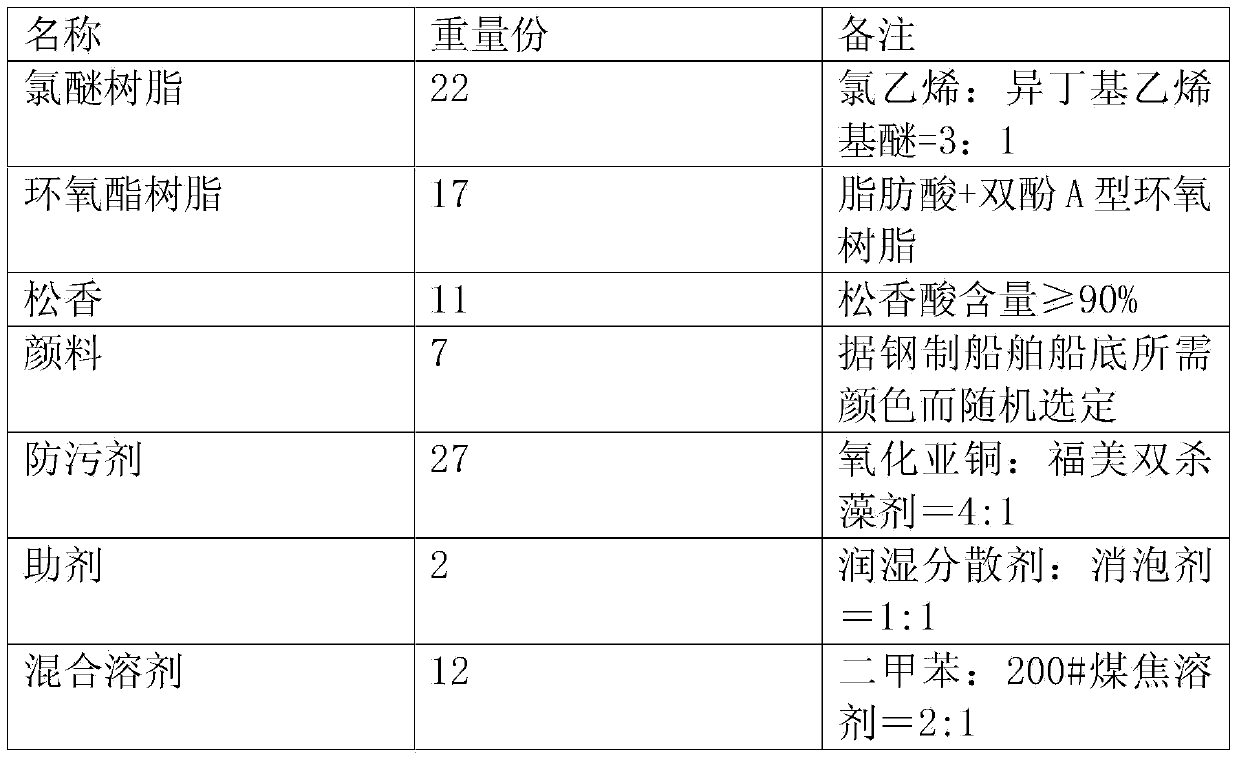

[0036] Example 1: Configure antifouling paint according to the table

[0037]

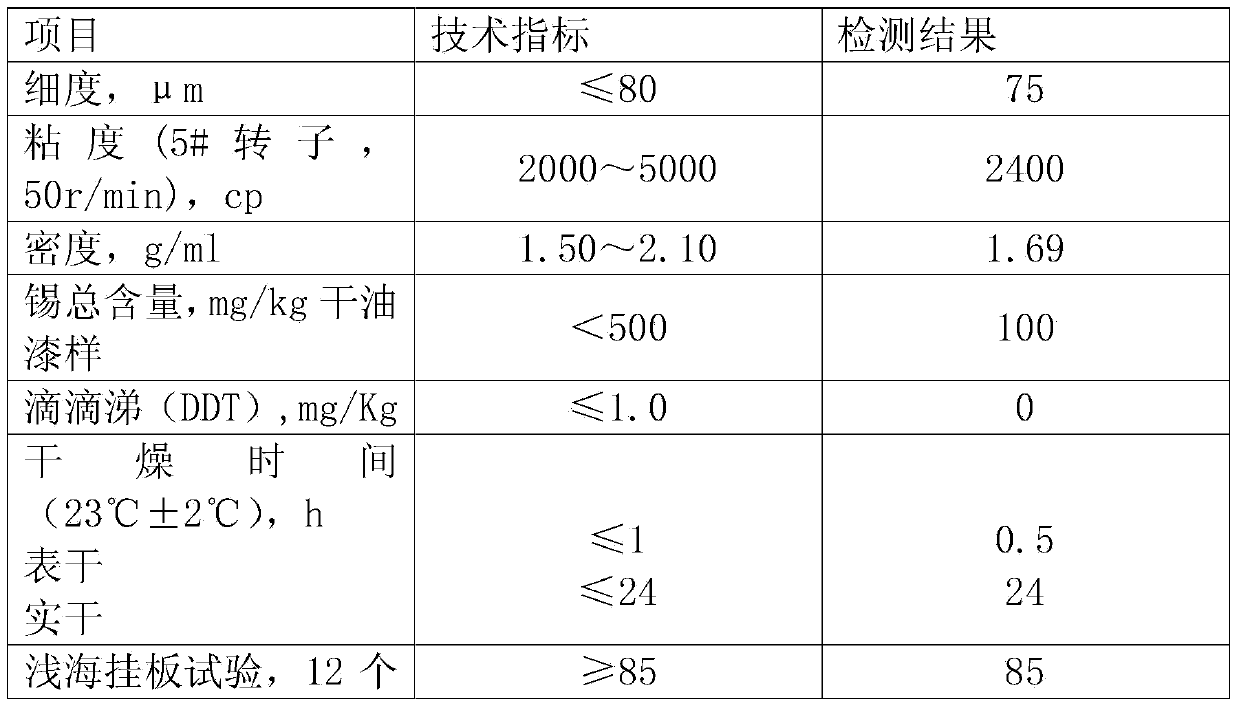

[0038] The above antifouling coatings are tested according to the national standard GB / T6822-2007 "Antifouling and antirust paint system for ship bottoms", and the crack resistance is tested according to the "sea water immersion low temperature drying test". The test results are shown in the table below.

[0039]

[0040]

[0041] Seawater immersion low-temperature drying test: soak the test sample coated with the above antifouling coating in 10°C seawater for 1 month, then put it in 0°C environment and dry it for 3 days, and then follow GB / T1766, 4.4, 4.7 An objective evaluation of the degree of cracking and spalling is specified and performed according to general criteria.

example 2

[0042] Example 2: Configure antifouling paint according to the table

[0043]

[0044] The above antifouling coatings are tested according to the national standard GB / T6822-2007 "Antifouling and antirust paint system for ship bottoms", and the crack resistance is tested according to the "sea water immersion low temperature drying test". The test results are shown in the table below.

[0045]

[0046]

[0047] See example 1 for seawater immersion low temperature drying test.

example 3

[0048] Example 3: Configure antifouling paint according to the table

[0049]

[0050] The above antifouling coatings are tested according to the national standard GB / T6822-2007 "Antifouling and antirust paint system for ship bottoms", and the crack resistance is tested according to the "sea water immersion low temperature drying test". The test results are shown in the table below.

[0051]

[0052]

[0053] See example 1 for seawater immersion low temperature drying test.

[0054] Show by above-mentioned each table parameter, antifouling paint of the present invention has following characteristics:

[0055] 1. Does not contain organic tin TBT and DDT poisonous materials banned internationally.

[0056] 2. It can be used on the bottom of steel ships, with 1 to 3 years of antifouling effect and low configuration cost.

[0057] 3. The antifouling coating overcomes physical defects such as cracking and falling off, and has excellent physical and mechanical properties....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com