Amylase mutant having improved heat stability and construction method and application thereof

An amylase and mutant technology, applied in the field of acid amylase mutants and their preparation, can solve the problems of limited thermal stability and limited application scope of amylase, and achieve shortened transformation time, broad application prospects, and thermal stability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Analysis and method of amylase thermostability mutation site

[0026] Through the analysis of amylase sequence (SEQ ID NO.1) and 3D spatial structure, several amino acid residues (Asn193, Met206, Lys240, Ser242, Gly180, Ile181) related to the improvement of the thermal stability of the active center were determined.

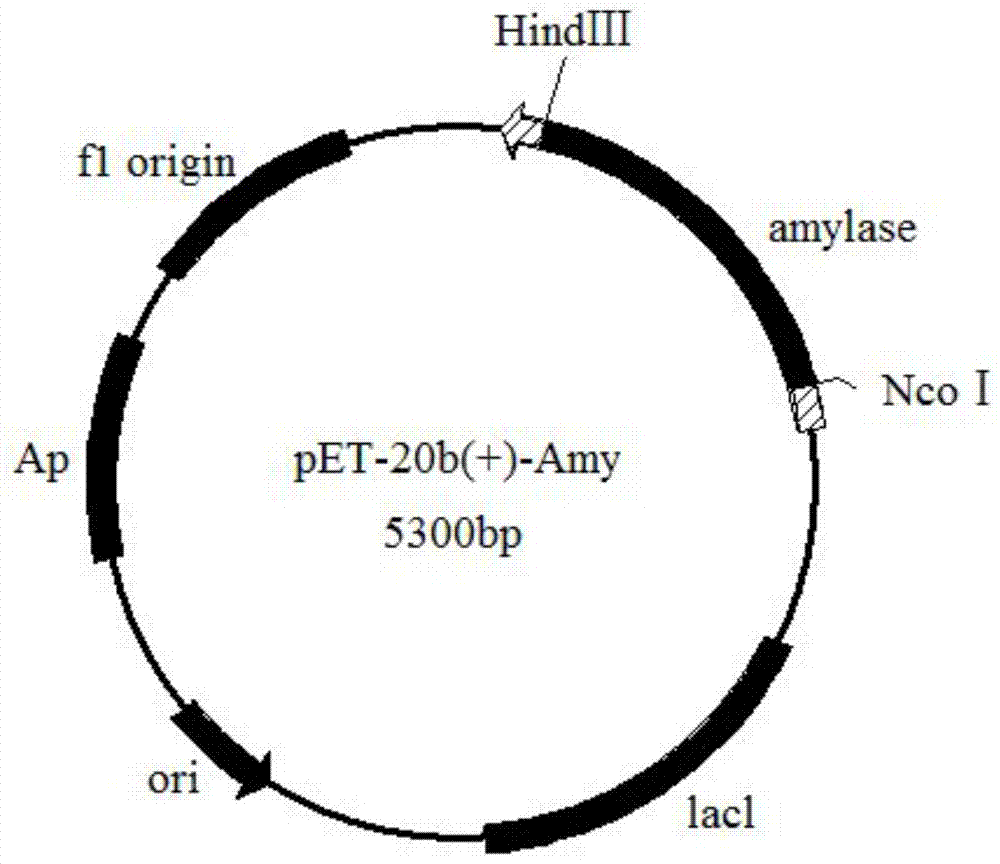

[0027] According to the amylase sequence of Bacillus stearothermophilus, the amylase was fully synthesized by a chemical total synthesis method, and then cloned into the plasmid pET-20b(+) to construct the recombinant plasmid pET-20b(+)-Amy.

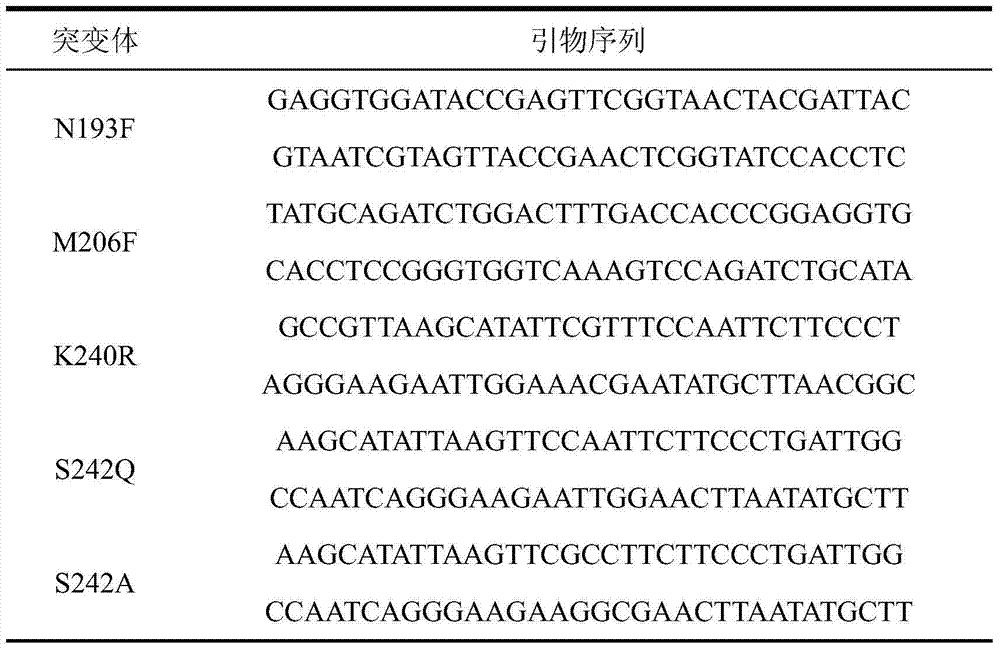

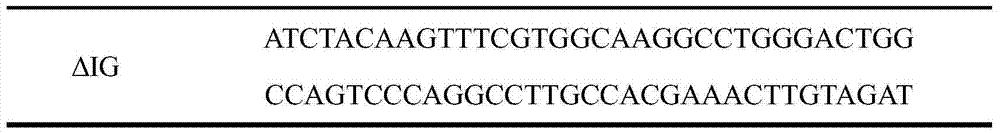

[0028] For site-directed mutagenesis at different sites, corresponding site-directed mutagenesis primers were designed (Table 1). Using site-directed mutagenesis primers and recombinant plasmid pET-20b(+)-Amy, the amylase was subjected to site-directed mutagenesis. PCR enzyme was used to amplify the recombinant plasmid pET-20b(+)-Amy with mutant primers. The amplified PCR product was treated with Dpn I t...

Embodiment 2

[0057] Embodiment 2: Amylase activity assay method

[0058] Determination of amylase activity by DNS method:

[0059] 1) Preparation of DNS reagent: Weigh 6.5g of 3,5-dinitrosalicylic acid and dissolve it in a small amount of water, transfer it into a 1L volumetric flask, add 262mL of 2mol / L sodium hydroxide solution, then add 185g of potassium sodium tartrate and 5g of phenol and 5g of anhydrous sodium sulfite, dilute to 1L, store in a brown bottle, and place in a refrigerator at 4°C until

[0060] use.

[0061] 2) Preparation of glucose standard curve: glucose solutions with different concentrations of 0.1g / L-1.0g / L were prepared. Mix 2mL of different concentrations of glucose with 3mL of DNS solution, put them in a boiling water bath, and keep the water bath for 7min. Cool with cold water, dilute to 15mL, A 540 Measure the absorbance. With the glucose concentration as the abscissa and the absorbance as the ordinate, a standard curve was made.

[0062] Definition of en...

Embodiment 3

[0063] Example 3: Determination and Analysis of Thermostability of Amylase at 95°C

[0064] The amylase was treated under the conditions of 20% glycerol, pH 6.0, and 95°C, samples were taken regularly, and the residual enzyme activity was measured by the method in Example 2. The half-life T1 / 2 of amylase is the time when the residual enzyme activity is half of the initial enzyme activity.

[0065] Table 2 Thermostability of single point mutant recombinant amylase at 95°C

[0066]

[0067] It was found by measurement that the half-lives of single mutants N193F, M206F, K240R, S242Q, S242A, and ΔIG at 95°C (Table 2) were all increased, and the effect of the ΔIG mutant was the most significant, with the half-life increased to 6 times the original. On this basis, N193F, S242Q, and ΔIG were selected for combined mutations to obtain four mutants, N193F / S242Q, N193F / ΔIG, S242Q / ΔIG, and N193F / S242Q / ΔIG. It was found by measuring their half-lives at 95°C (Table 3 ) have been improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com