Method for preparing LiFePO4 positive electrode material through carbon cladding and Na+ doping in one step

A positive electrode material and carbon coating technology, which is applied in the synthesis and performance improvement of lithium-ion battery positive electrode materials, can solve the problems of limiting industrialization process, slow diffusion speed, low electronic conductivity, etc., and achieve good rate and cycle performance, sample The effect of performance improvement and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] One step of the present invention realizes carbon coating and Na + Preparation of LiFePO by doping 4 The method of positive electrode material

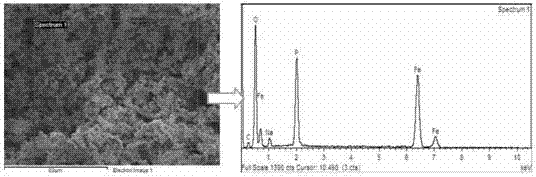

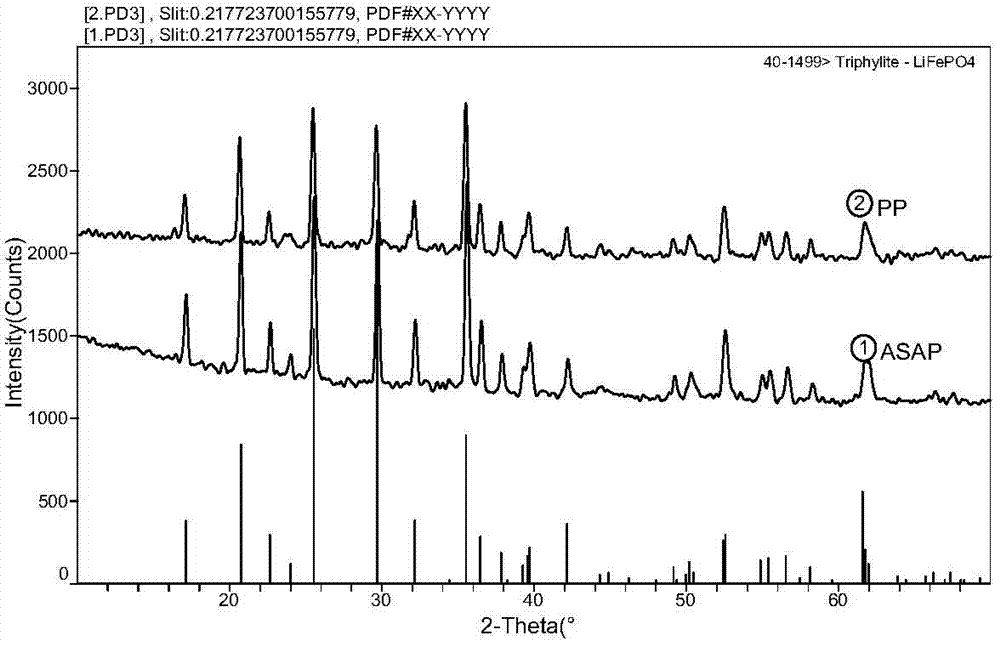

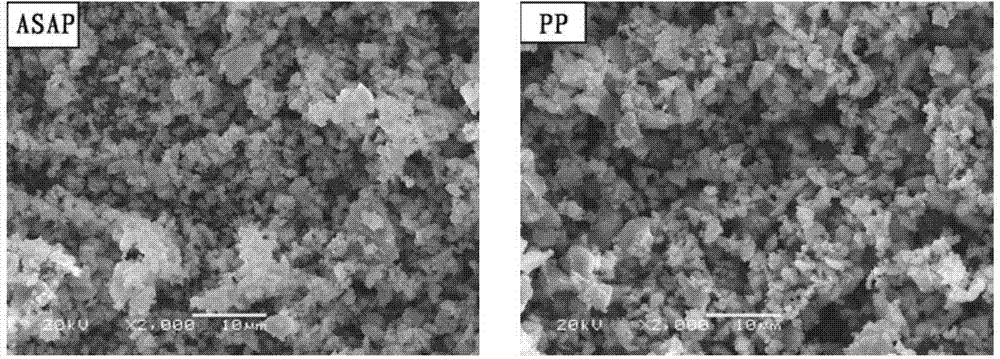

[0029] Will Li 2 CO 3 (97%, AR), FePO 4 4H 2 O (98%, AR) is weighed at a molar ratio of 1:2, and sodium polyacrylate (polypropylene) is weighed with Li 2 CO 3 (97%, AR) with FePO 4 4H 2Weigh 10% of the O(98%, AR) mass sum, put it into a ball mill jar, add the dispersant absolute ethanol to 1 / 3 of the height of the ball mill jar, and then perform ball milling. After ball milling for 12 hours, dry in an oven at 70°C for 8 hours. After grinding evenly, burn at 700°C for 8 hours in a nitrogen-filled tube furnace to obtain carbon-coated and Na+-doped LiFePO 4 Cathode material.

Embodiment 2

[0031] Preparation of LiFePO by Reduction of Polymer Pyrolysis 4 Lithium-ion battery cathode material

[0032] LiOH·H 2 O (AR, 90%), Fe (NO 3 ) 3 9H 2 O (AR, 98.5%) and NH 4 h 2 PO 4 (AR, 99.0%) and dissolved in acrylic acid solution containing cross-linking agent in a given proportion, nitrogen gas was passed into the solution under constant stirring, an appropriate amount of initiator was added, and it was polymerized at 80°C. Then place it in an oven at 120° C. for 12 hours to obtain a polyacrylate polymer precursor. Then it was fired at 800° C. for 5 h in a tube furnace with nitrogen gas to obtain the product. During the burning process, due to the reducing atmosphere formed by the pyrolysis of organic matter, ferric iron can be reduced to ferrous iron, thereby generating LiFePO, a product containing cracked carbon. 4 Material.

Embodiment 3

[0034] Li site doping to prepare Li 0.95 Na 0.05 FePO 4 / C and its electrochemical performance

[0035] All raw materials in the preparation process are analytically pure, first CH 3 COOLi, NH 4 h 2 PO 4 and CH 3 COONa was dissolved in distilled water at a molar ratio of 0.95:1:0.05, and then FePO 4 Powder, conductive agent and reducing agent acetylene black are added to the mixture. The mixture was sonicated for 12 h to make it well mixed. Then in a nitrogen environment, the temperature was raised to 650°C at a rate of 2°C / Min, and then the temperature was kept at a constant temperature for 7 hours and then naturally cooled to room temperature to obtain Li0.95Na0.05FePO 4 / C composite product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com