Superhydrophobic and superlipophilic sponge as well as preparation method and application of superhydrophobic and superlipophilic sponge

A super-oleophilic and super-hydrophobic technology, applied in the direction of separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve the problems of cumbersome preparation process and decreased oil absorption capacity, and achieve simple preparation process, Not easy to fall off, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Synthesis of polyacrylate emulsion: Add 15g methyl methacrylate, 25g butyl acrylate, 0.7g acrylic acid, 1.4g hydroxypropyl acrylate, 1.3g allyloxynonylphenol polyoxyethylene to a 250mL beaker Ether (10) ammonium sulfate and 44 g of distilled water were stirred at a high speed for 15 minutes at a stirring rate of 3000 r / min to obtain an acrylate pre-emulsion. 0.4 g of potassium persulfate was dissolved in 5 g of distilled water to obtain an aqueous initiator solution. Add 25ml of distilled water into a four-necked flask equipped with a thermometer, a stirring paddle, a condenser and a constant pressure funnel, heat it to 80°C in a constant temperature water bath, and slowly add the above-mentioned acrylate pre-emulsion and initiator aqueous solution to four In the flask, the dropwise addition time is 2h, and the reaction is continued for 1h after the dropwise addition is completed to obtain a polyacrylate emulsion.

[0030] (2) Synthesis of fluorine-containing polya...

Embodiment 2

[0041] The difference between this example and Example 1 is that the amount of dodecafluoroheptyl methacrylate in step (2) is changed to 6g, and the amount of silicon dioxide in step (3) is changed to 0.6g to obtain superhydrophobic and superphilic Oil sponge, the gasoline used in step (4) is changed to n-hexane.

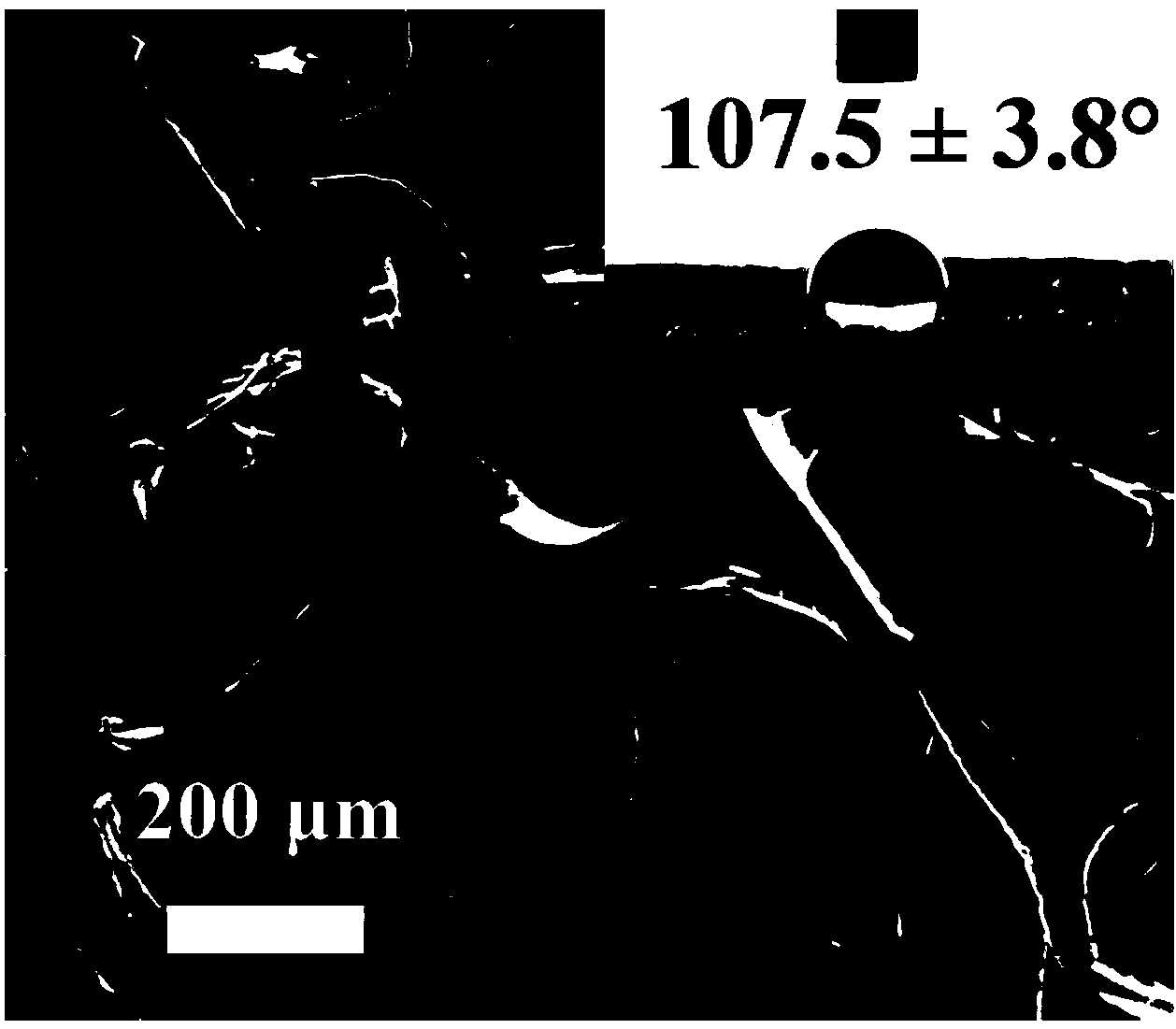

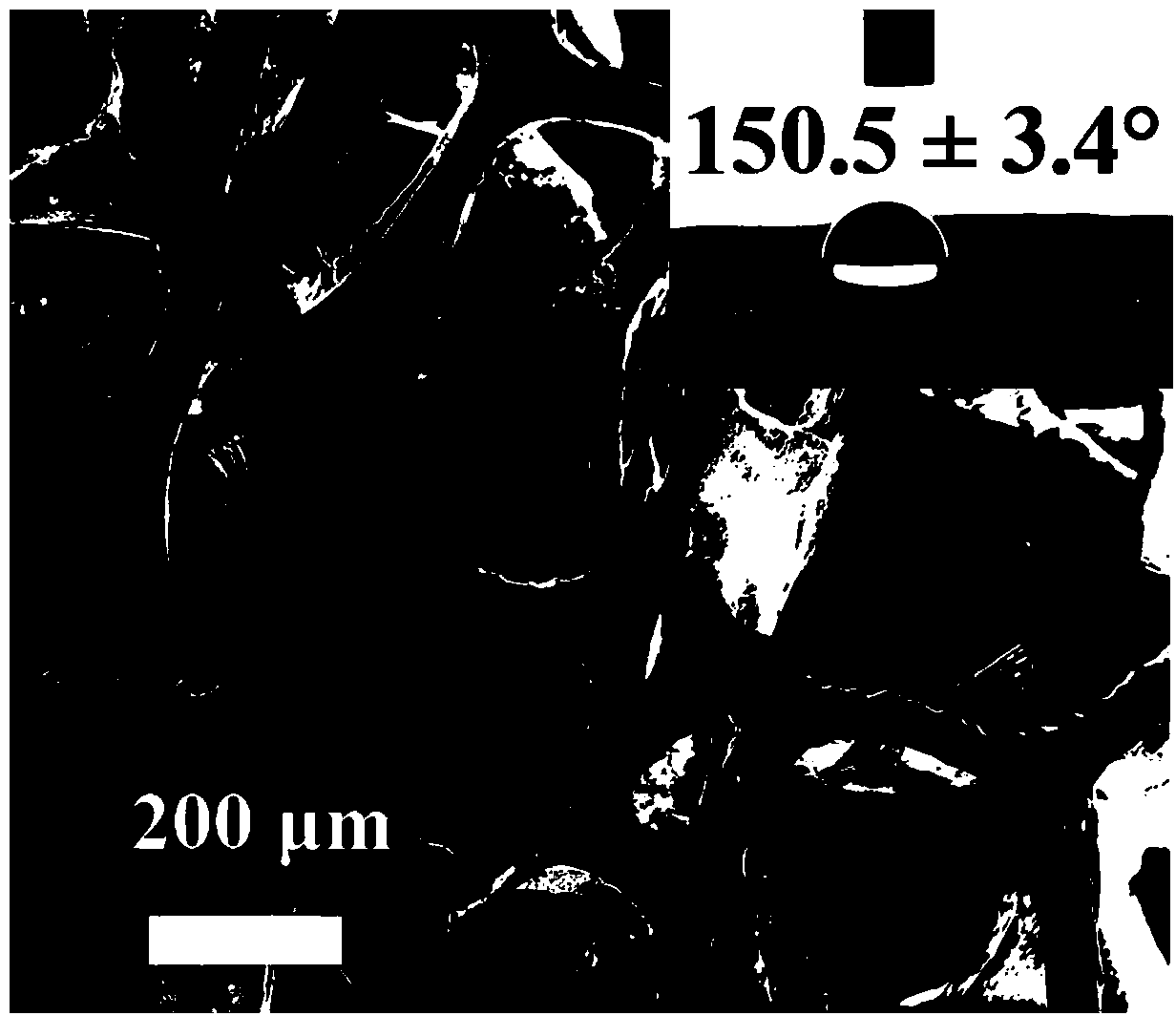

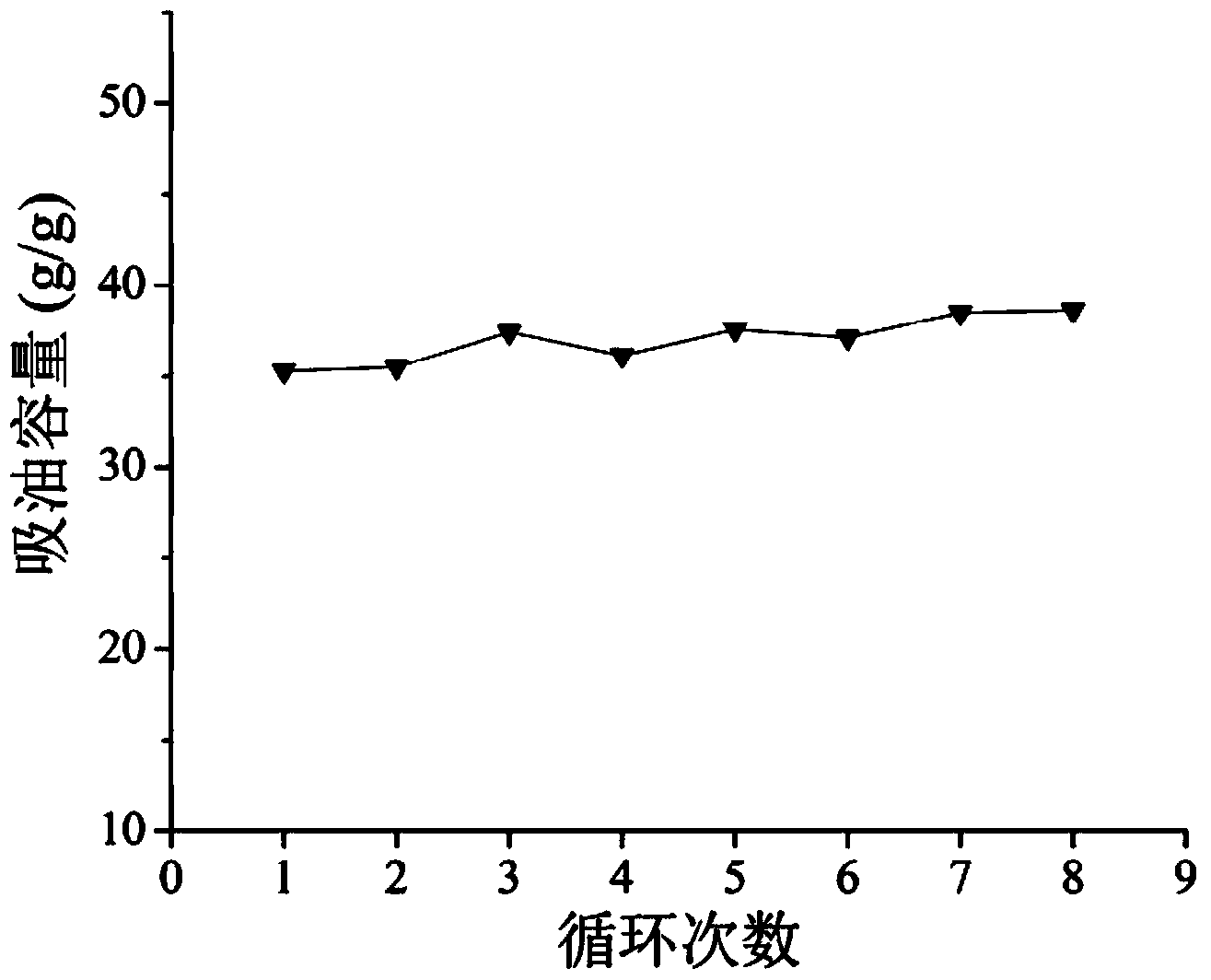

[0042] SEM photographs of the obtained superhydrophobic and superoleophilic sponges and figure 2 Similar; the contact angle tester (DSA100, Germany) test shows that the prepared superhydrophobic and superoleophilic sponge and water contact angle are 148.8 °, and the contact angle with n-hexane is 0 °, and the sponge of this embodiment can quickly and effectively remove water / The oil absorption capacity of n-hexane in the n-hexane mixture is 27g / g, and the oil absorption capacity is basically unchanged after repeated use.

Embodiment 3

[0044] (1) Synthesis of polyacrylate emulsion: Add 15g styrene, 25g isooctyl acrylate, 1.6g methacrylic acid, 2.4g hydroxyethyl acrylate, 1.5g allyloxynonylphenol polyoxyethylene to a 250mL beaker Ether (10) ammonium sulfate and 55 g of distilled water were stirred at a high speed for 15 minutes at a stirring rate of 2500 r / min to obtain an acrylate pre-emulsion. 0.3 g of ammonium persulfate was dissolved in 10 g of distilled water to obtain an aqueous initiator solution. Add 40g of distilled water into a four-necked flask equipped with a thermometer, stirring paddle, condenser and constant pressure funnel, heat it to 80°C in a constant temperature water bath, and slowly add the above-mentioned acrylate pre-emulsion and initiator aqueous solution to four In the mouth bottle, the dropwise addition time is 2.5h. After the dropwise addition is completed, the reaction is continued for 1h to obtain a polyacrylate emulsion.

[0045] (2) Synthesis of fluorine-containing polyacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com