Nitrogen-doped graphene nanobelt and preparation method thereof

A nitrogen-doped graphene and nanobelt technology, applied in graphene, nanocarbon, nanotechnology and other directions, can solve the problems of difficulty in size control and low yield, and achieve a simple preparation process, lower reaction temperature, and easily controllable conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

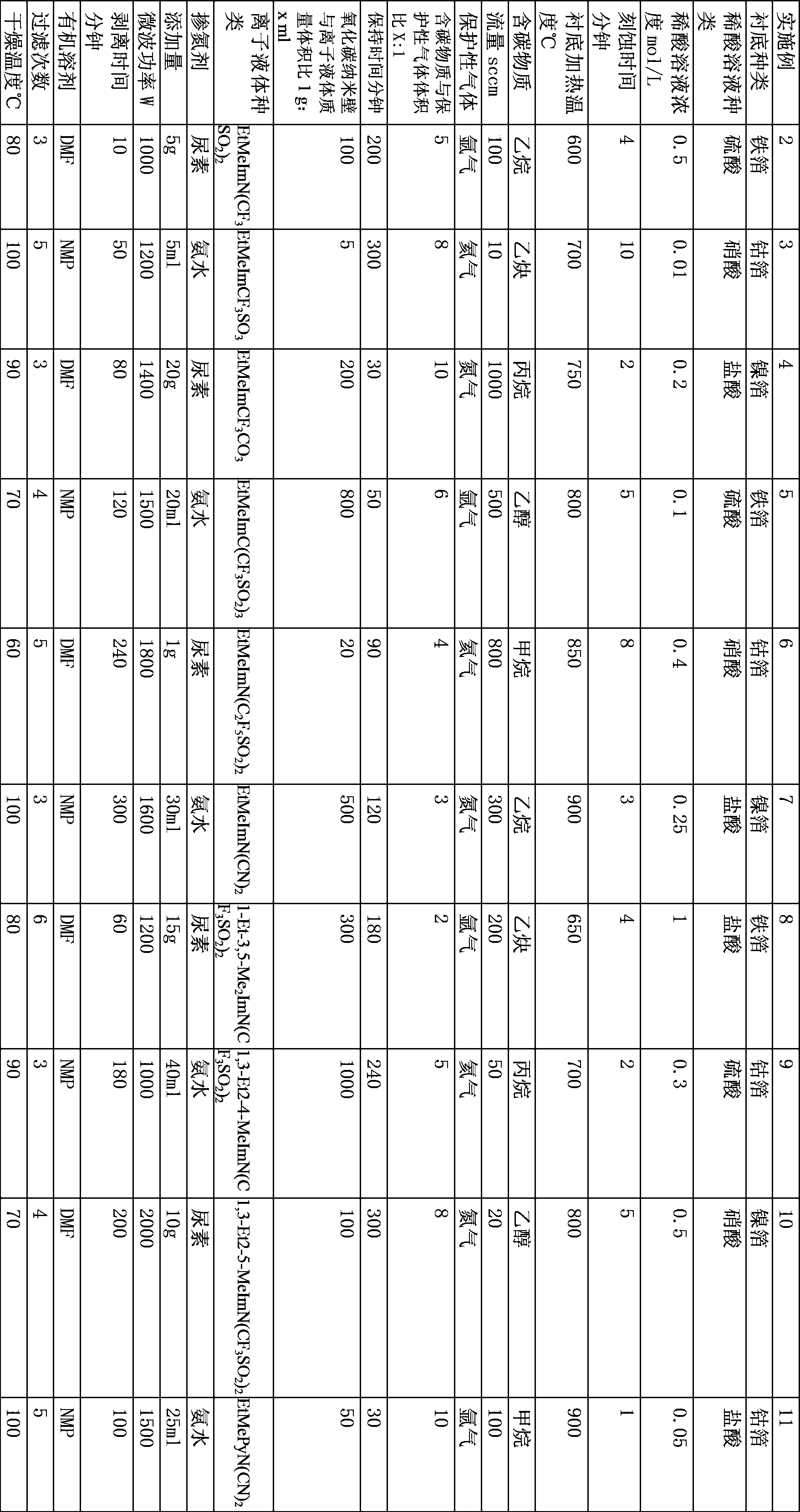

[0024] The preparation process of the nitrogen-doped graphene nanobelt of the present invention is roughly divided into the following steps: 1. Etching the substrate: putting the substrate into a dilute acid solution with a concentration of 0.01 to 1mol / L and etching it for 0.5 to 10 minutes, Clean with deionized water, ethanol, acetone after etching.

[0025] The purpose of this step is to: produce defects on the etched surface of the metal substrate by etching the metal substrate, effectively improve the surface structure of the metal substrate, and enable carbon nanowalls to grow on the surface of the metal substrate.

[0026] Wherein, the preferred time for etching the metal substrate is 60-180 seconds, and the preferred acid solution concentration for etching the metal substrate is 0.1-0.5 mol / L. The above optimal etching conditions can achieve a good etching effect and improve the growth efficiency of the carbon nanowall.

[0027] 2. Preparation of carbon nanowall: Put ...

Embodiment 1

[0039] Example 1: 1. Etching the substrate: put the nickel foil into a dilute hydrochloric acid solution with a concentration of 1 mol / L and etch for 0.5 minutes, and clean it with deionized water, ethanol, and acetone after etching.

[0040] 2. Preparation of carbon nanowall: Put the cleaned nickel foil into the reaction chamber and remove the air in the reaction chamber, heat the nickel foil to 900°C, and then turn on the ultraviolet light source equipment to irradiate the ultraviolet light on the nickel foil On the surface, carbonaceous material methane (flow rate of 200sccm) and protective gas nitrogen are introduced, and the volume ratio of methane to nitrogen is 2:1, and kept for 100 minutes.

[0041] After the reaction is completed, stop feeding the carbon-containing substances, stop heating the nickel foil and turn off the light source equipment, stop feeding the protective gas after the reaction chamber is cooled to room temperature, and obtain a carbon nanometer wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com