Preparation method for magnetic polymer microspheres capable of adsorbing Cr in contaminated soil

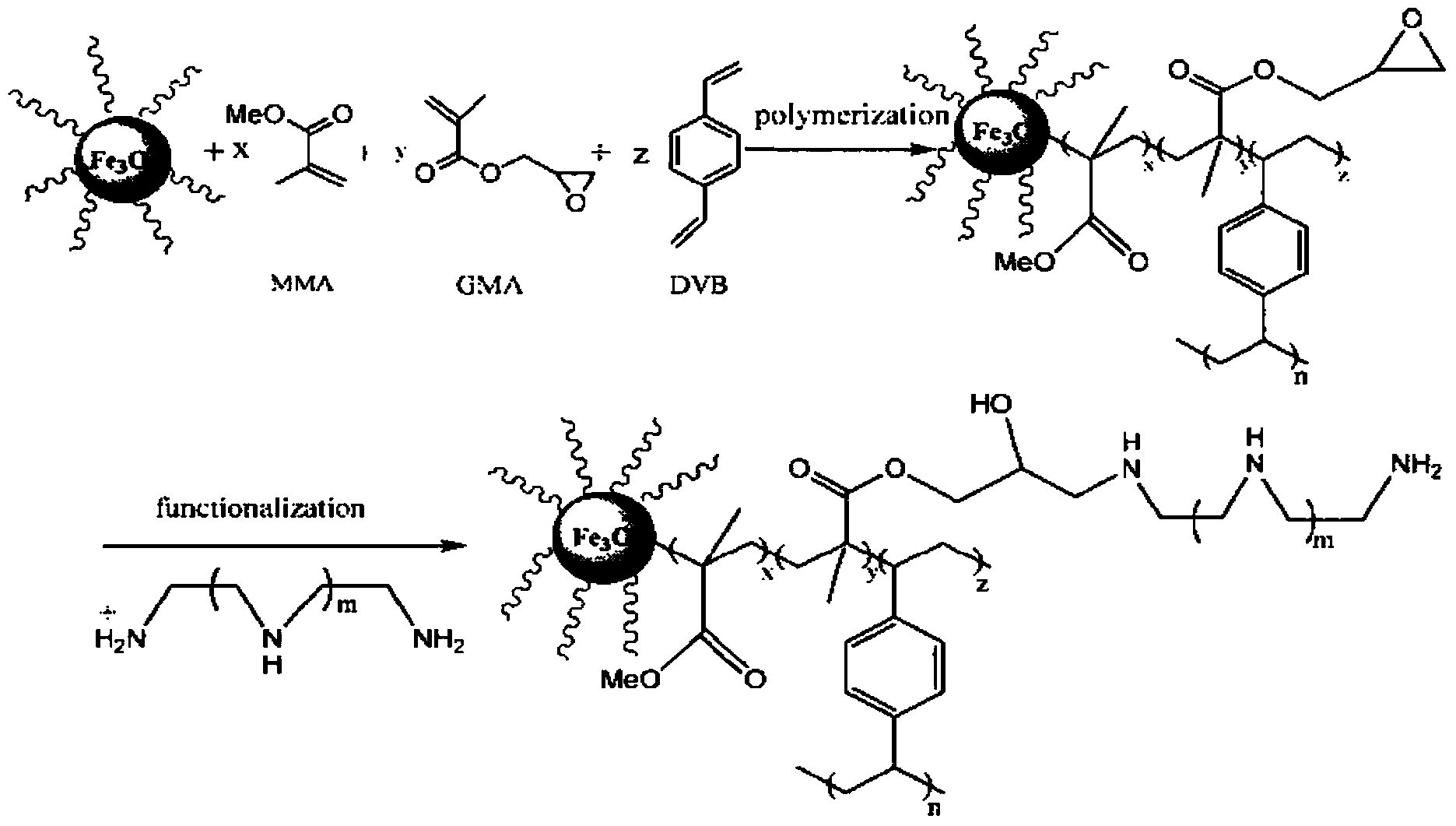

A technology of polymer microspheres and magnetic microspheres, which is applied in the field of environmental restoration, can solve the problems of time-consuming, complicated and high-cost preparation process, and achieve the effects of short reaction time, uniform particle size and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

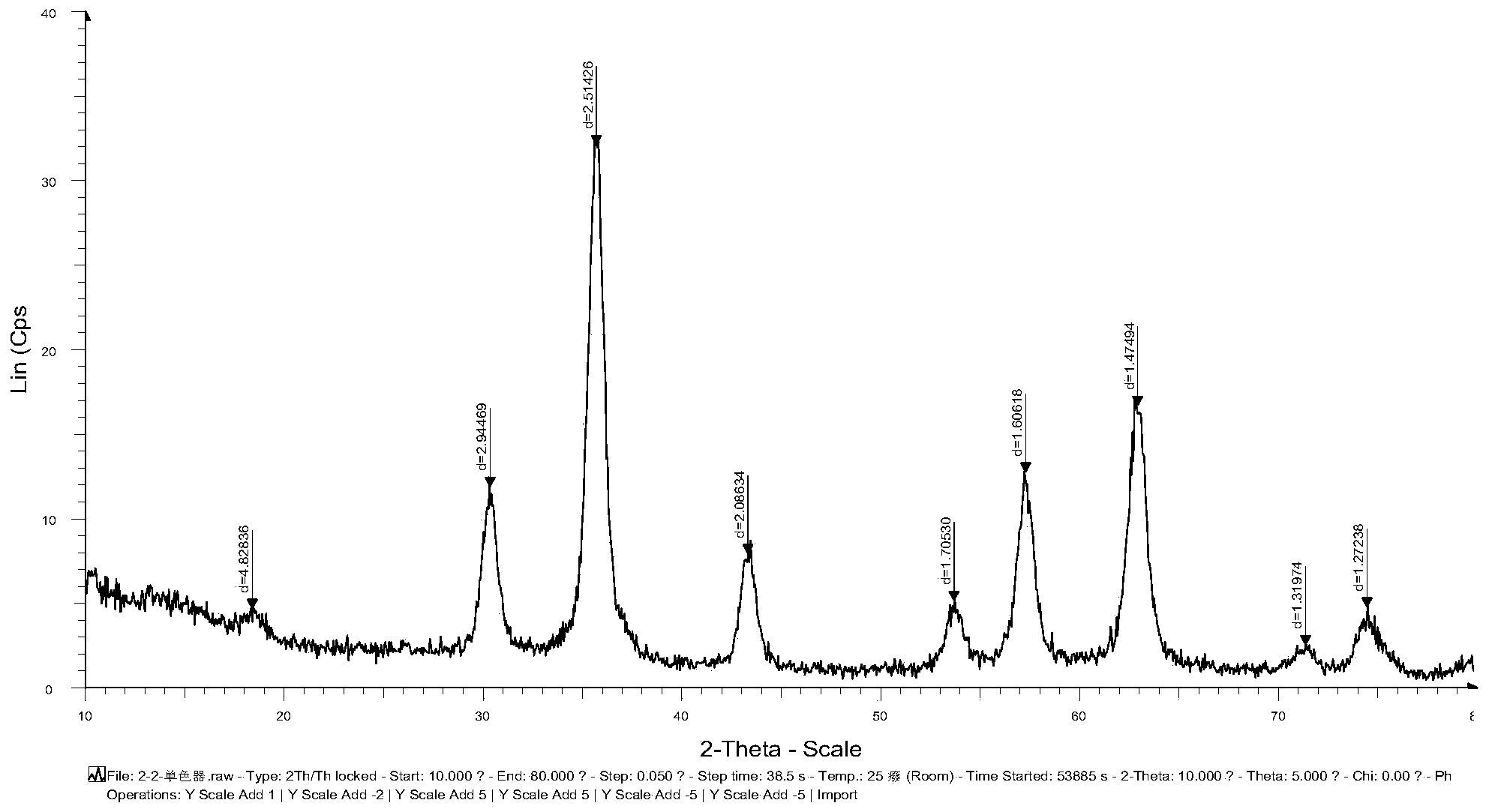

[0029] Embodiment 1: Preparation of magnetic polymer microspheres

[0030] Step (1): Fe 3 o 4 Preparation of ferrofluid

[0031] in N 2 Under gas protection, add 200mL deionized water to a 500mL four-neck flask, then add 5.41g FeCl 3 ·6H 2 O and 1.99gFeCl 2 4H 2 O, under strong stirring, quickly add concentrated ammonia water with a mass concentration of 29-30% at a rate of 2-3 drops / s to make the pH of the solution between 8-10, and stop stirring after 30 minutes of reaction. Wash 4-6 times with deionized water.

[0032] Step (2): Preparation of Oleic Acid Modified Ferrofluid

[0033] Pour 90mL of deionized water and 110mL of ethanol into the four-necked flask, then add the Fe3O4 magnetic fluid prepared in step (1) to re-disperse, and in a constant temperature water bath at 60°C, at a rate of 1-2 drops per second Add 1.5mL of oleic acid, stir and react for 1 hour to obtain a well-dispersed black magnetic fluid. After cooling, magnetically wash with deionized water un...

Embodiment 2

[0038] Embodiment 2: Preparation of magnetic polymer microspheres

[0039] Step (1): Fe 3 o 4 Preparation of ferrofluid

[0040] in N 2 Under gas protection, add 200mL deionized water to a 500mL four-neck flask, then add 5.41g FeCl 3 ·6H 2 O and 2.78g FeSO 4 ·7H 2 O Under strong stirring, quickly add concentrated ammonia water to make the pH of the solution between 8-10, and stop stirring after 30 minutes of reaction. Wash 4-6 times with deionized water.

[0041] Step (2): Preparation of Oleic Acid Modified Ferrofluid

[0042] Inject 100mL of deionized water and 100mL of ethanol into the four-necked flask, then add the Fe3O4 magnetic fluid prepared in step (1) to redisperse, and drop in 2mL of oleic acid in a constant temperature water bath at 60°C, and stir for 1 hour to obtain The black magnetic fluid with good dispersibility was cooled and magnetically washed with deionized water to neutrality, and then washed with ethanol, and then vacuum-dried at 60°C for 12 hour...

Embodiment 3

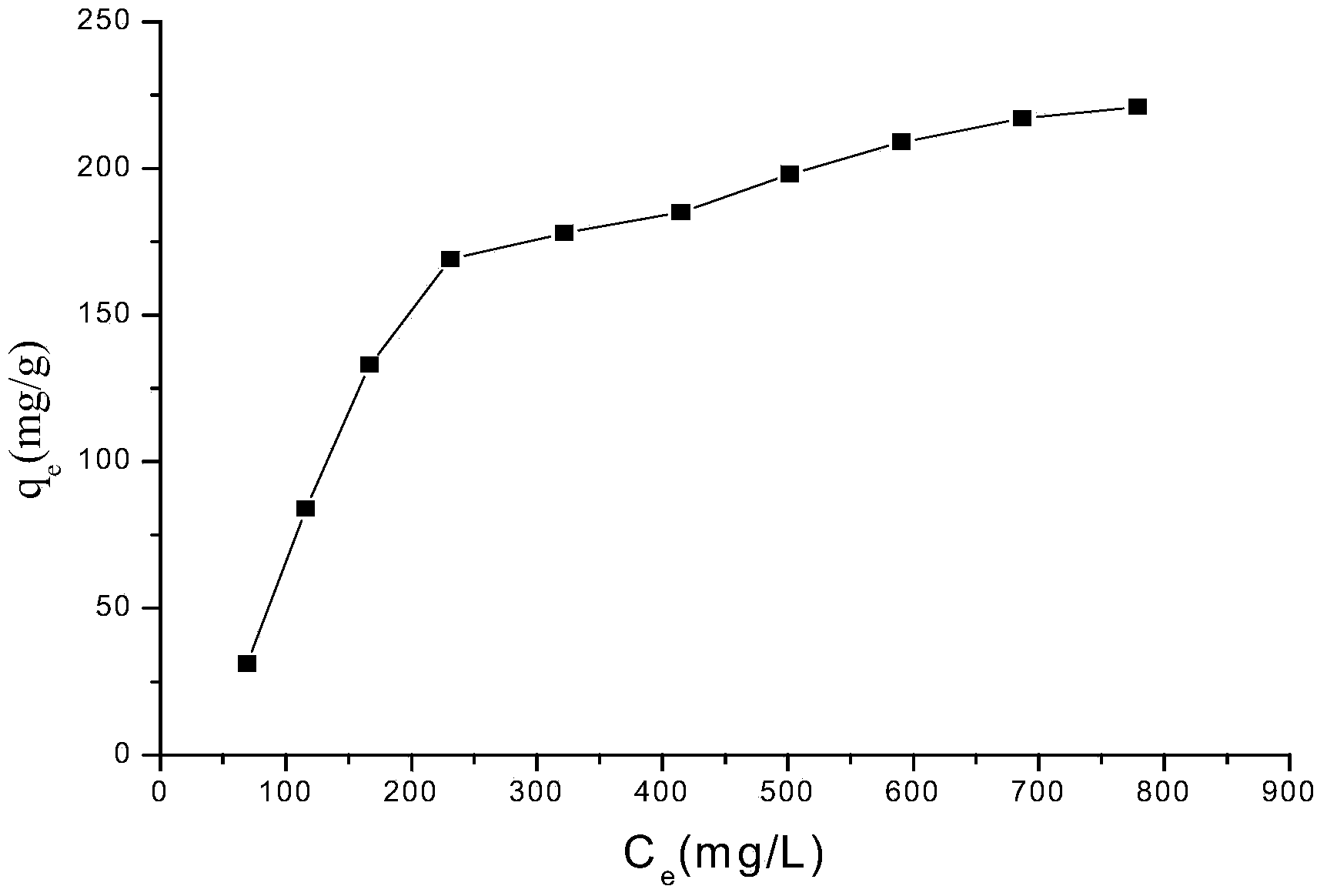

[0047] Example 3: Adsorption of Cr by amino functional magnetic polymer microspheres

[0048] Take 50ml of Cr solutions with concentrations of 100mg / L, 200mg / L, 300mg / L, 400mg / L, 500mg / L, 600mg / L, 700mg / L, 800mg / L, 900mg / L, 1000mg / L respectively, and take the above 0.05 g of the obtained amino magnetic microspheres were added to the Cr solution respectively, the adsorption temperature was 35 ° C, the pH was controlled at 2.5, and the constant temperature was oscillated for 24 hours. After the adsorption was completed, magnetic separation was carried out, and the solution was measured on a UV spectrophotometer Absorbance at 540nm, then calculate the concentration of Cr in the solution after adsorption equilibrium by the standard curve, and calculate the adsorption amount of magnetic microspheres according to the following formula:

[0049] q e = ( c 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com