Supercapacitor based on polypyrrole / manganese dioxide / carbon cloth and manufacturing method thereof

A supercapacitor, manganese dioxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of easy dissolution or corrosion of electrode active materials, complex production process, and high toxicity of materials. , to achieve the effect of improving electrochemical performance, wide range of sources and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

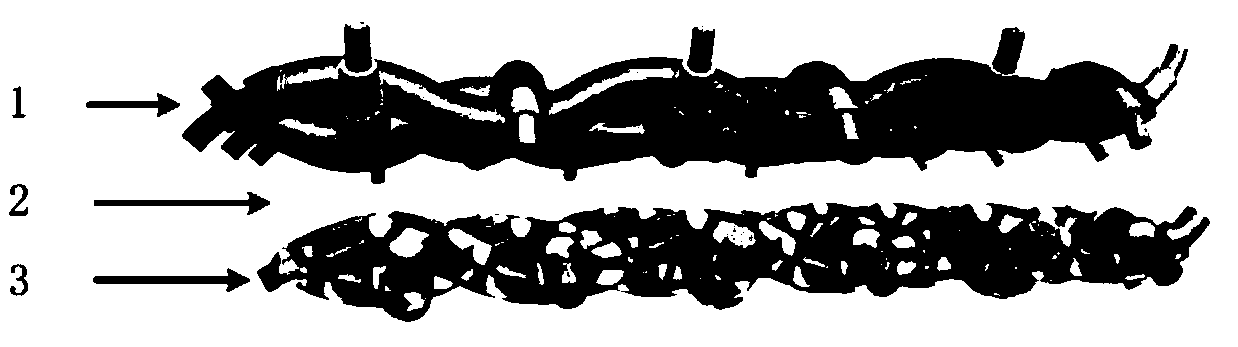

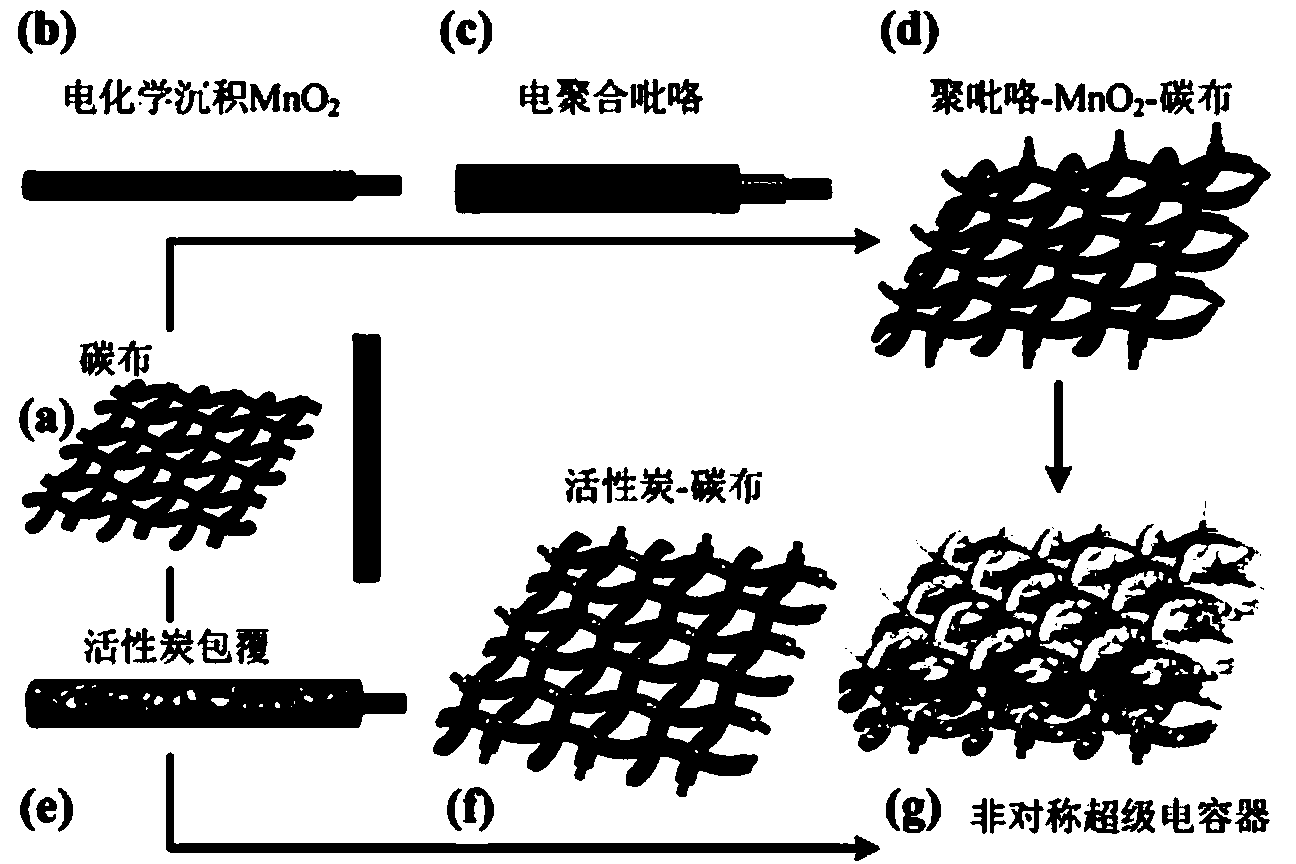

[0052] see figure 2 , shows the preparation method of the supercapacitor according to one embodiment of the present invention, which includes the following steps:

[0053] In step (a), two carbon cloths were taken for cleaning respectively, and were cleaned in sequence with acetone, alcohol and deionized water under ultrasonic waves, and finally dried in an oven to obtain a clean and dry carbon cloth as a current collector;

[0054] In step (b), use a mixed solution of sulfuric acid and manganese sulfate as the electrodeposition solution, connect one of the carbon cloths to the copper wire with silver paste, inject the mixed solution of sulfuric acid and manganese sulfate into the electrolytic cell, and use electrochemical depositing nanostructured manganese dioxide;

[0055] In step (c) and step (d), a mixed solution of sodium perchlorate and pyrrole monomer is used as the electropolymerization solution, the electropolymerization solution is injected into the electrolytic c...

Embodiment 1

[0063] 1) Preparation of electrode materials

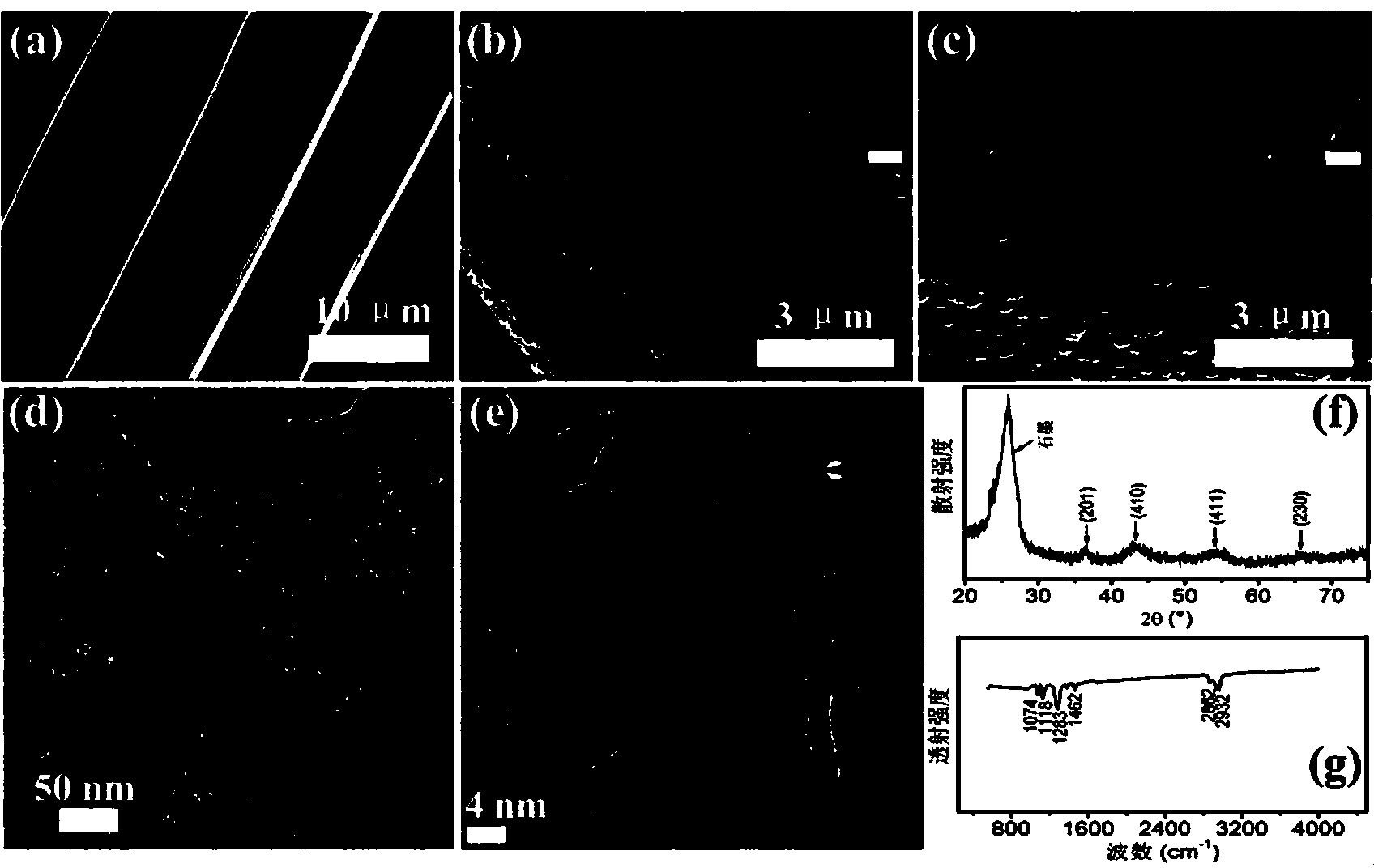

[0064] Take two carbon cloths with a thickness of about 274 microns and an area of about 1.5 square centimeters, clean them first, then use acetone, alcohol and deionized water to wash them under ultrasonic conditions for 15 minutes, and finally dry them in an oven to obtain a clean dry carbon cloth. The above-mentioned carbon cloth was cleaned with oxygen plasma for 10 minutes to carry out surface hydrophilic treatment. Connect the electrodes to one end of the carbon cloth with silver paste. Then put the carbon cloth into the electrolytic tank, inject a mixed solution of sulfuric acid and manganese sulfate with a concentration of 0.2 moles per liter into the tank, and use the constant current method to electrochemically deposit for 75 minutes, and the current density is 0.5mA cm -2 , depositing nanostructured manganese dioxide on carbon cloth.

[0065] Pour out the liquid in the electrolytic tank, inject 0.2 moles per liter ...

Embodiment 2

[0083] 1) Preparation of electrode materials

[0084] In this example, the preparation of the electrode material is different from Example 1 in that the electrochemical deposition time of manganese dioxide is 30 minutes; the electropolymerization time of pyrrole is 0.5 minutes, and the rest are the same.

[0085] 2) Assembly of supercapacitor

[0086] together with the examples.

[0087] 3) Performance testing of supercapacitor electrode materials

[0088] Figure 5 The electrode material performance test of this embodiment is included. Figure 5 In (a), after 30 minutes of electrochemical deposition of manganese dioxide on carbon cloth, when the discharge current density is 0.2mA cm -2 , the measured surface capacitance is 0.26F cm -2 , when the discharge current density increases to 10mA cm -2 , the measured surface capacitance is 0.11F cm -2 . Figure 5 (b), when the discharge current density increases 50 times, that is, from 0.2mA cm -2 increased to 10mA cm -2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com