Luteimonas sp., and preparation method and application thereof

A technology of L. luteus and strains is applied in the field of L. luteus and its preparation and application in oil production engineering, which can solve the problems of reducing and reducing the surface tension of fermentation broth and oil-water interfacial tension, and achieves broad application Prospects, Enhanced Oil Recovery, Effects of Oil Viscosity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

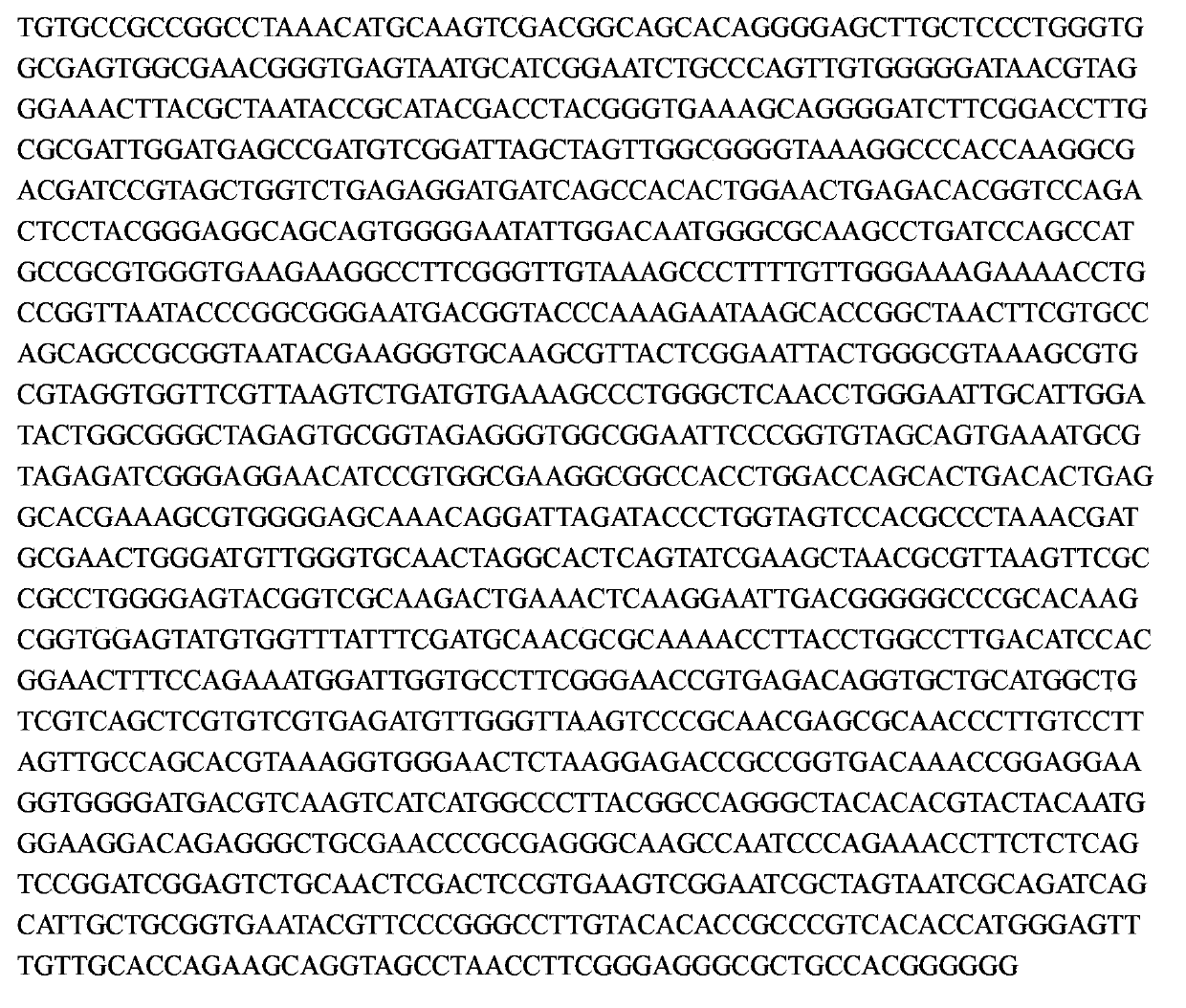

[0037] Example 1. Screening, cultivation and treatment effect on crude oil of Luteimonas sp. CGMCC No.6457

[0038] Screening and cultivation of Luteimonas sp. CGMCC No.6457:

[0039] Add 99mL oil well produced liquid sewage into a 250mL Erlenmeyer flask, and then add 1% medium, and vibrate at a constant temperature for 18-24 hours at a temperature of 45°C. The mass percentage of each component of the medium is:

[0040] Glucose 2%, peptone 0.05%, yeast powder 0.05%, urea 0.05%, ammonium sulfate 0.05%, potassium dihydrogen phosphate 0.5%, magnesium sulfate heptahydrate 0.02%, sodium chloride 0.01%, and the rest is output liquid sewage. Cultivate at a temperature of 25-30°C for 3-5 days, then use a sterile pipette to draw 1mL of the above bacterial solution into a test tube filled with 9mL sterile water and mix well to prepare 10 -1 , 10 -2 , 10 -3 , 10 -4 , 10 -5 , 10 -6 different dilutions. from 10 -2 , 10 -3 , 10 -4 Pipette 100ul of each of the three tubes of dilu...

Embodiment 2

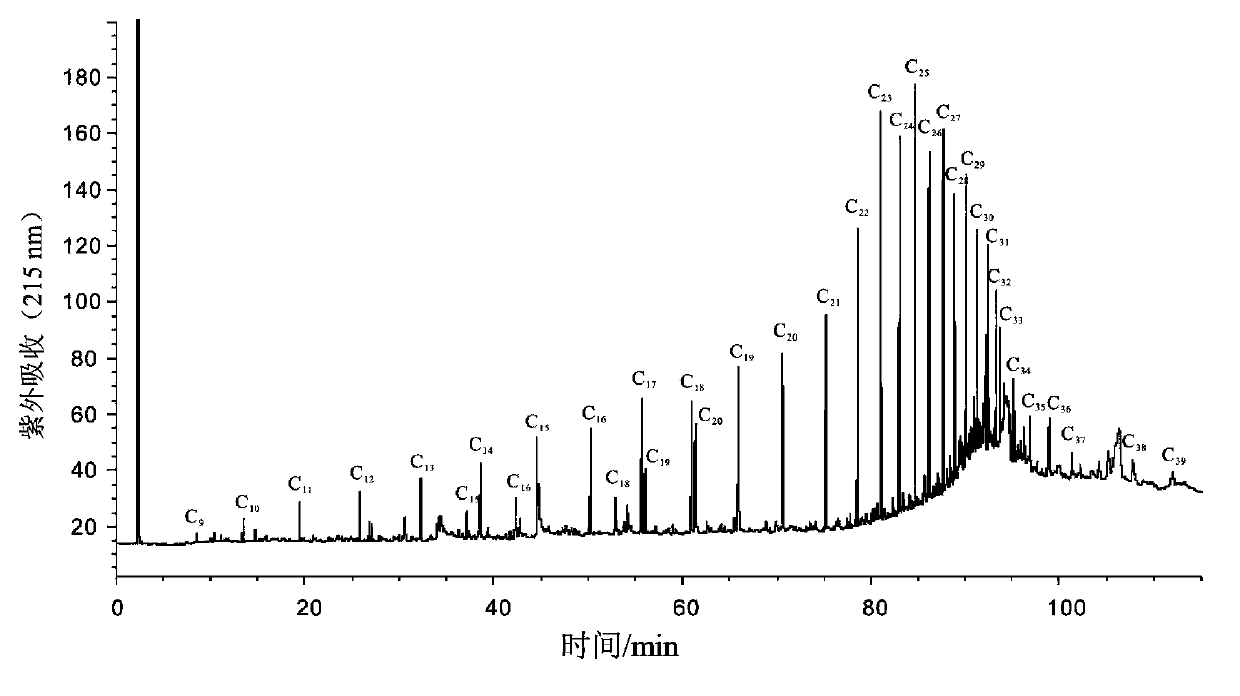

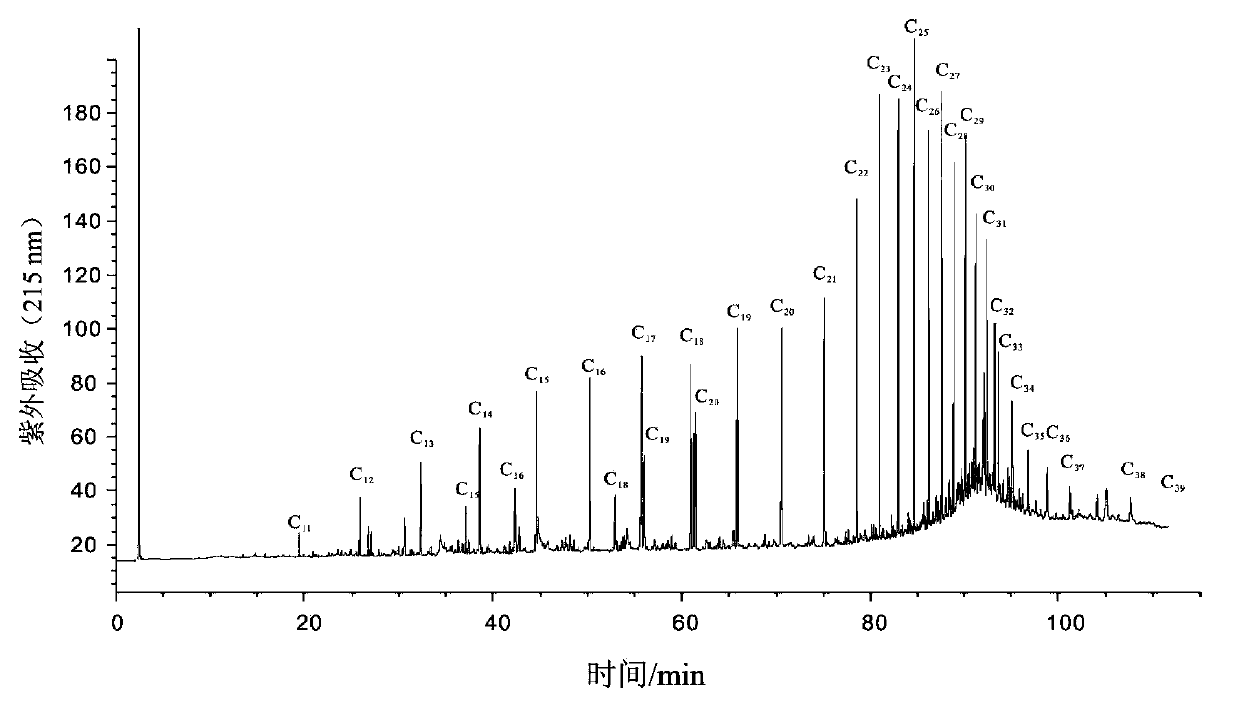

[0045] Embodiment 2, metabolite analysis

[0046] The strain Luteimonas sp. CGMCC No.6457 was activated for 24 hours, and then transferred to the enrichment medium (glucose 2%, peptone 0.05%, yeast powder 0.05%, urea 0.05 %, 0.05% ammonium sulfate, 0.5% potassium dihydrogen phosphate, 0.02% magnesium sulfate heptahydrate, 0.01% sodium chloride, prepared from tap water), cultured on a shaker at a temperature of 45°C and a speed of 150rpm for 2 days, and the fermentation broth was Metabolite analysis, the analysis process is as follows:

[0047] (1) Determination of surfactants

[0048] Take 50mL fermentation broth, filter and extract 3 times with 100mL ether, evaporate the ether to dryness and collect the extract, add 2mL of 6mol / L hydrochloric acid solution, seal and hydrolyze, evaporate to dryness, add 0.500mL silanization derivatization reagent solution at 60 Reaction for 20 minutes at Celsius, measured by GC-MS, identified derivatized amino acids and hydroxy fatty acids, ...

Embodiment 3

[0052] Embodiment 3, indoor physical model flooding experiment

[0053] Experimental model: The artificially filled sandstone core pipe model used in the experiment has a length of 100cm and an inner diameter of 2.5cm.

[0054]

[0055] Experimental water, oil, bacteria liquid:

[0056] The experimental water is the produced water of Baolige Oilfield, which belongs to NaHCO 3 Type, the salinity is 7105mg / L.

[0057] The oil used in the experiment is crude oil from Well Ba51-34 in Baolige Oilfield, with a viscosity of 525mP.S.

[0058] The bacterial solution used in the experiment is Luteimonas sp. CGMCC No.6457 The micro-drive nutrient solution used in the experiment is 0.6% glucose, 0.1% peptone, 0.08% yeast extract, 0.1% ammonium chloride, 0.1% dihydrogen phosphate Sodium, 0.02% potassium dihydrogen phosphate, the total concentration is 1.0%.

[0059] The experimental operation is as follows: the core is evacuated and saturated with formation water, injected with satu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com