Rechargeable magnesium battery positive electrode material with nano porous metal sulfide and application method thereof

A metal sulfide and nanoporous technology, applied in battery electrodes, chemical instruments and methods, nickel sulfide, etc., can solve the problem of less positive electrode materials and achieve good reversibility, small particles, and good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

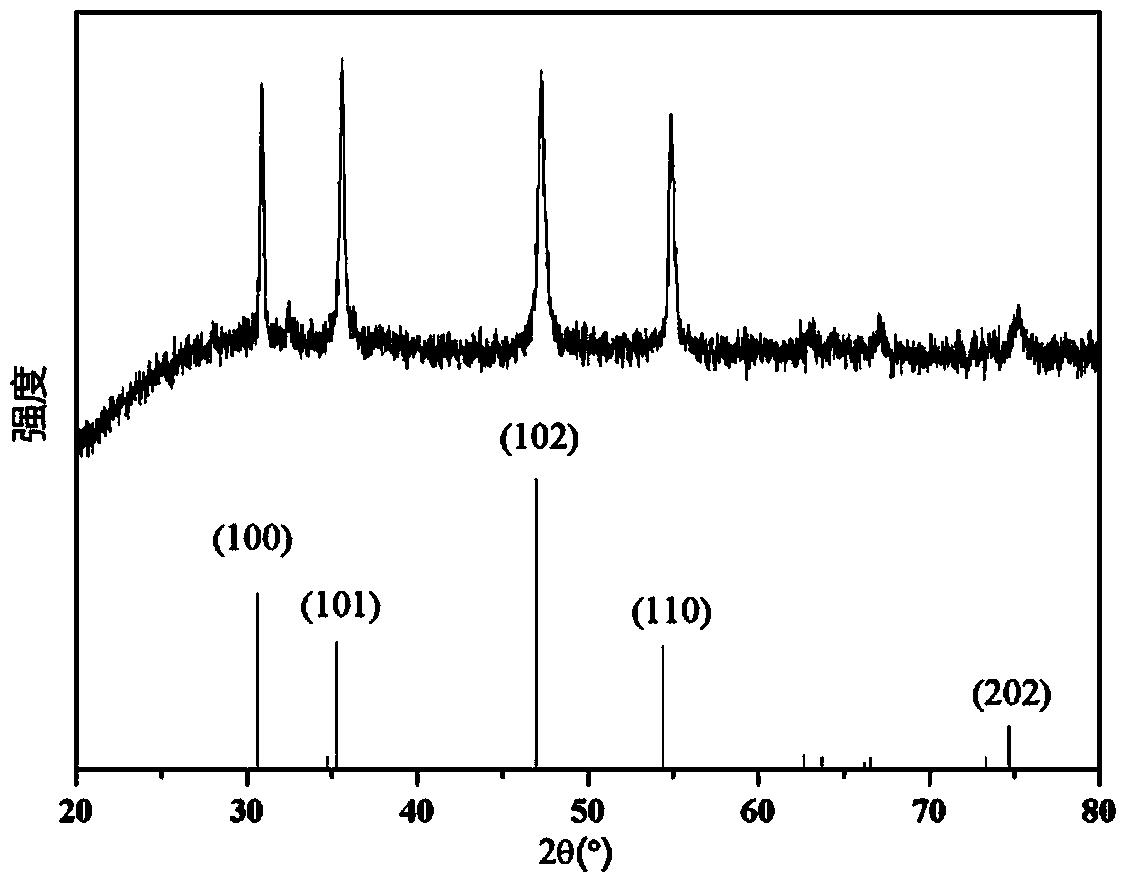

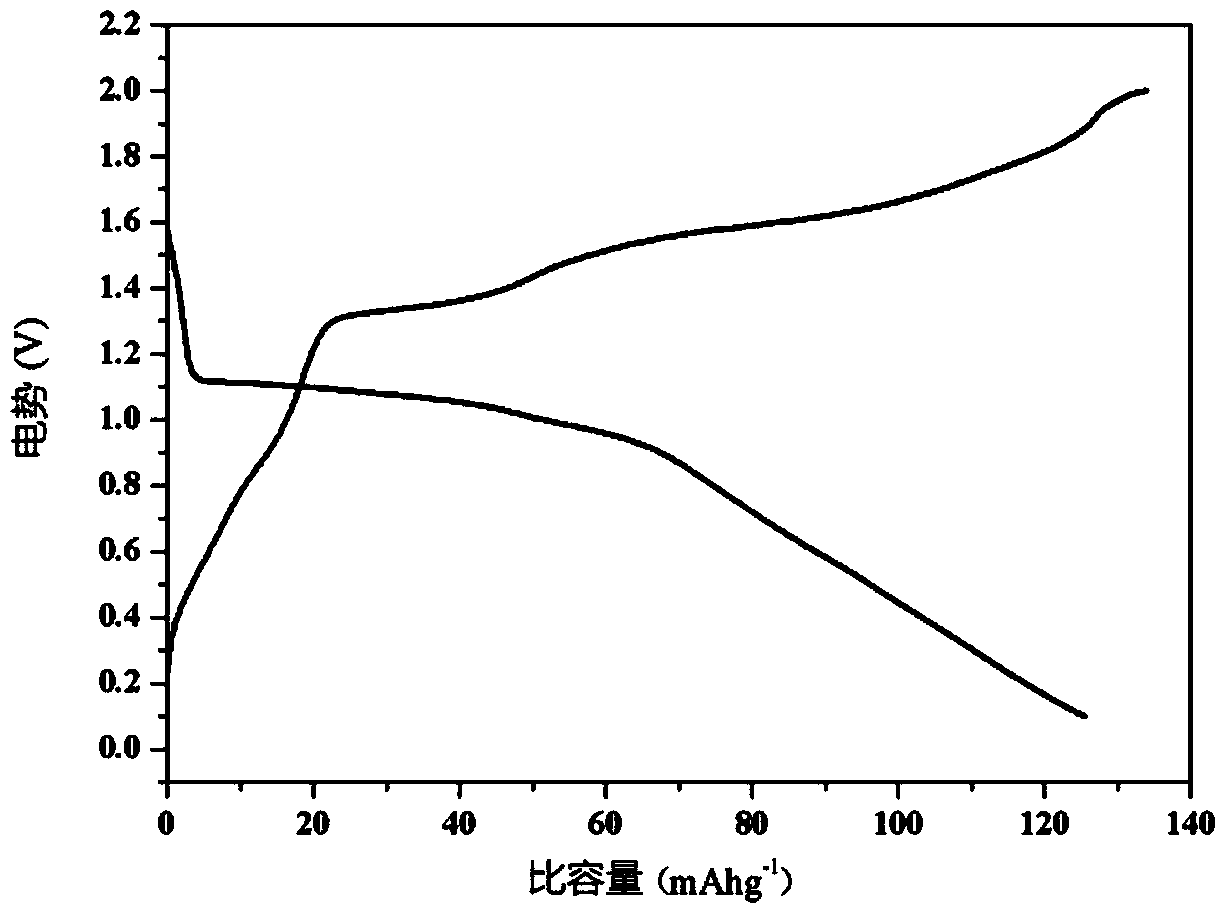

[0036] Example 1: Preparation and Application of Compound CoS

[0037] 1. Weigh 60 mL of deionized water and 15 mL of ethylene glycol into a measuring cylinder, mix well and use it as a reaction solvent.

[0038] 2, with cobalt chloride (CoCl 2 ·6H 2 O), cysteine (C 3 H 7 NO 2 S) as the raw material, weighed according to the atomic molar ratio of Co:S=1:3, dissolved in a mixed solvent, and stirred evenly with a magnetic stirrer, then the mixed solution was moved to a stainless steel reaction kettle with a PTFE lining , the solution is pink.

[0039] 3. Transfer the sealed reaction kettle to the oven, slowly heat up to 200°C, keep the temperature for 20h and then cool down with the oven.

[0040] 4. The reacted solution (including the black precipitate) was continuously washed and filtered by deionized water and ethanol to remove the organic matter and inorganic ions coated on the surface of the product. The product was put into a vacuum oven and dried at a temperature...

Embodiment 2

[0045] Example 2: Compound Ni 0.5 CoS 2 preparation and application of

[0046] 1. Nickel sulfate (Ni(SO 4 ) 2 ·6H 2 O), cobalt chloride (CoCl) 2 ·6H 2 O) and thiourea (CH 4 N 2 S) as the raw material, according to the atomic molar ratio Ni:C o :S=1:2:12 The ratios of raw materials were weighed, dissolved in water, and the mixed solution was moved to a stainless steel reaction kettle with a teflon lining after strong stirring by a magnetic stirrer.

[0047] 2. Transfer the above reaction kettle to an oven, heat up to 180°C, keep the temperature for 15h and then cool down with the oven.

[0048] 3. The reacted solution (including the black precipitate) was continuously washed and filtered by deionized water and ethanol to remove the organic matter and inorganic ions coated on the surface of the product. The product was put into a vacuum oven and dried at a temperature of 60 °C for 10 h to prepare electrode sheets and conduct electrochemical tests.

[0049] The applic...

Embodiment 3

[0050] Example 3: Compound Fe 0.1 Preparation and application of CoS

[0051] 1. With ferrous sulfate (Fe(SO 4 ) 2 ·6H 2 O), cobalt sulfate (CoSO 4 ·7H 2 O) and thioacetamide (C 2 H 5 NS) as the raw material, weigh the raw materials according to the atomic molar ratio Fe:Co:S=1:8:18, dissolve them in ethylene glycol, and stir them evenly with a magnetic stirrer. Teflon-lined stainless steel reactor.

[0052] 2. Transfer the above reaction kettle to an oven, heat up to 160°C, keep the temperature for 20h and then cool down with the oven.

[0053] 3. The reacted solution (including the black precipitate) was continuously washed and filtered by deionized water and ethanol to remove the organic matter and inorganic ions coated on the surface of the product. The product was put into a vacuum oven and dried at a temperature of 60 °C for 10 h to prepare electrode sheets and conduct electrochemical tests.

[0054] The application and testing method of the positive electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com