A gene carrier imitating cell outer layer membrane structure and its preparation method

A technology imitating the outer membrane of cells and structural genes, which is applied in the field of nanotechnology and biomedical polymer materials, can solve the problems of low density of phosphorylcholine groups and limit biocompatibility, and achieve platelet adhesion reduction, Effect of biocompatibility improvement and load capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]The imitation cell outer membrane structure gene carrier of the present embodiment is made by free radical polymerization of 2-methacryloyloxyethyl phosphorylcholine (MPC), aniline and dendritic polyurethane, wherein the monomer (2-methyl The mass of 2-methacryloyloxyethylphosphorylcholine and aniline is 60% of the total mass of monomer and polycation (dendritic polyurethane), and the mass ratio of 2-methacryloyloxyethylphosphorylcholine to aniline It is 2:1.

[0031] The preparation method of this embodiment is: dissolving 0.1g of dendritic polyurethane in 50mL of acetic acid aqueous solution with a concentration of 1% by volume, stirring for 24h to obtain a dendritic polyurethane solution; then adding 0.1g of 2-methyl Acryloyloxyethylphosphorylcholine (MPC), 0.05g aniline and 5mg potassium persulfate (K 2 S 2 o 8 , KPS), under the protection of nitrogen, the polymerization reaction was carried out at a temperature of 70 °C for 4 hours; after the polymerization react...

Embodiment 2

[0034] The imitation cell outer membrane structure gene carrier of the present embodiment is made by free radical polymerization of 2-methacryloyloxyethyl phosphorylcholine (MPC), aniline and chitosan, wherein the monomer (2-methyl The mass of 2-methacryloyloxyethylphosphorylcholine and aniline is 65% of the total mass of monomer and polycation (chitosan), and the mass ratio of 2-methacryloyloxyethylphosphorylcholine to aniline It is 4:1.

[0035] The preparation method of this embodiment is: dissolving 0.35g chitosan in 50mL of 5% acetic acid aqueous solution by volume percentage concentration, stirring for 24h to obtain a chitosan solution; then adding 0.52g 2-methyl Acryloyloxyethylphosphorylcholine, 0.13g aniline and 0.02g potassium persulfate (K 2 S 2 o 8 , KPS), under the protection of nitrogen, the polymerization reaction was carried out at a temperature of 80°C for 3h; after the end of the polymerization reaction, the reaction system was suction filtered with a G3 f...

Embodiment 3

[0038] The imitation cell outer membrane structure gene carrier of the present embodiment is made by free radical polymerization of 2-methacryloyloxyethyl phosphorylcholine (MPC), aniline and chitosan, wherein the monomer (2-methyl The mass of 2-methacryloyloxyethylphosphorylcholine and aniline is 70% of the total mass of monomer and polycation (chitosan), and the mass ratio of 2-methacryloyloxyethylphosphorylcholine to aniline is 6:1.

[0039] The preparation method of the present embodiment is: dissolving 0.3g chitosan in 50mL of 3% aqueous acetic acid solution by volume, stirring for 12h to obtain a chitosan solution; then adding 0.6g 2-methyl Acryloyloxyethylphosphorylcholine (MPC), 0.1g of aniline and 5mg of potassium persulfate (K 2 S 2 o 8 , KPS), under the protection of nitrogen, the temperature is 70 ° C under the conditions of polymerization for 3 hours; after the end of the polymerization reaction, filter the reaction system with a G3 funnel to obtain the filtrat...

PUM

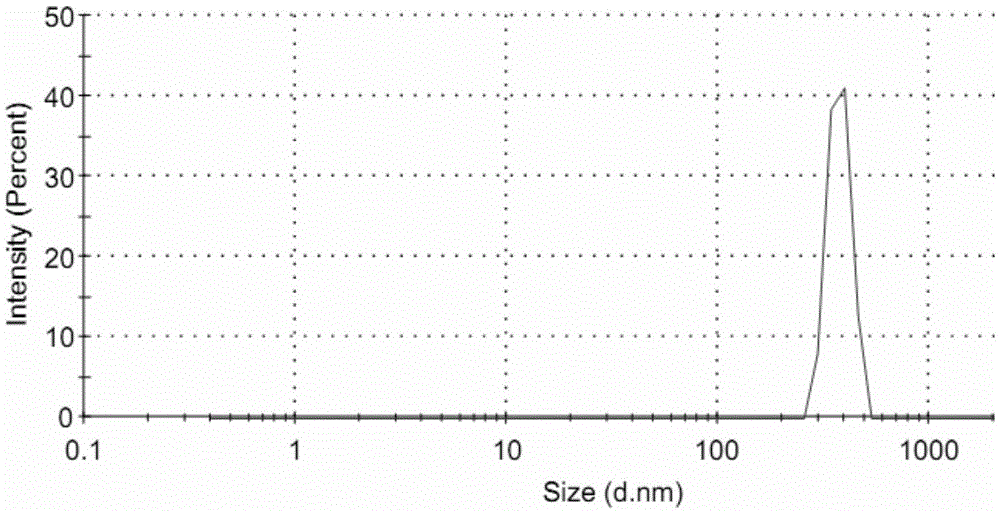

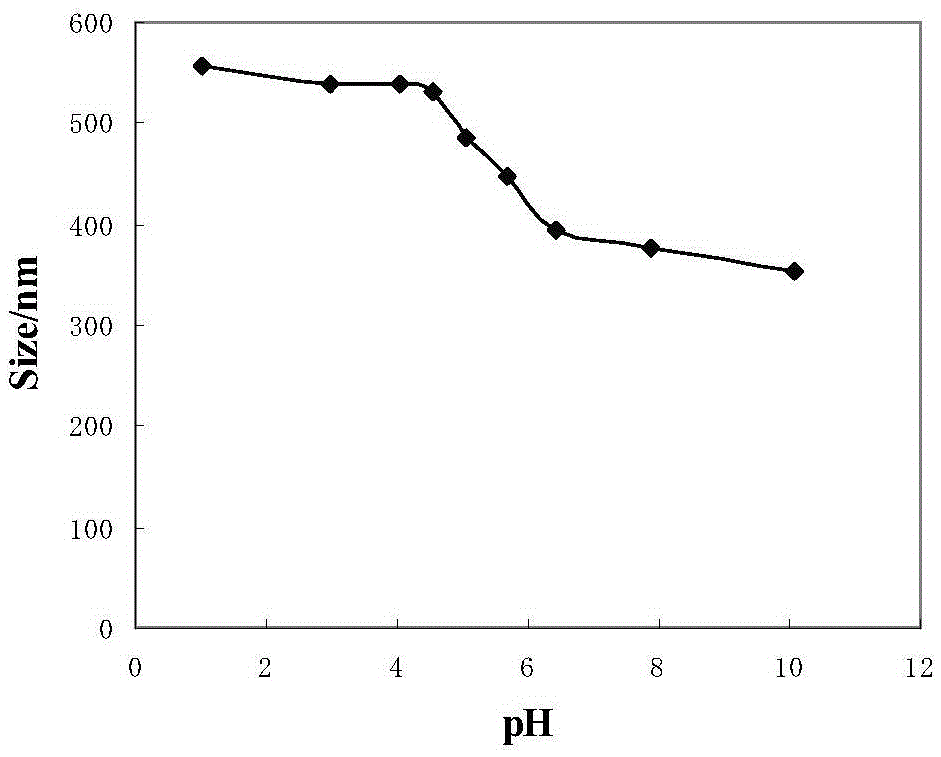

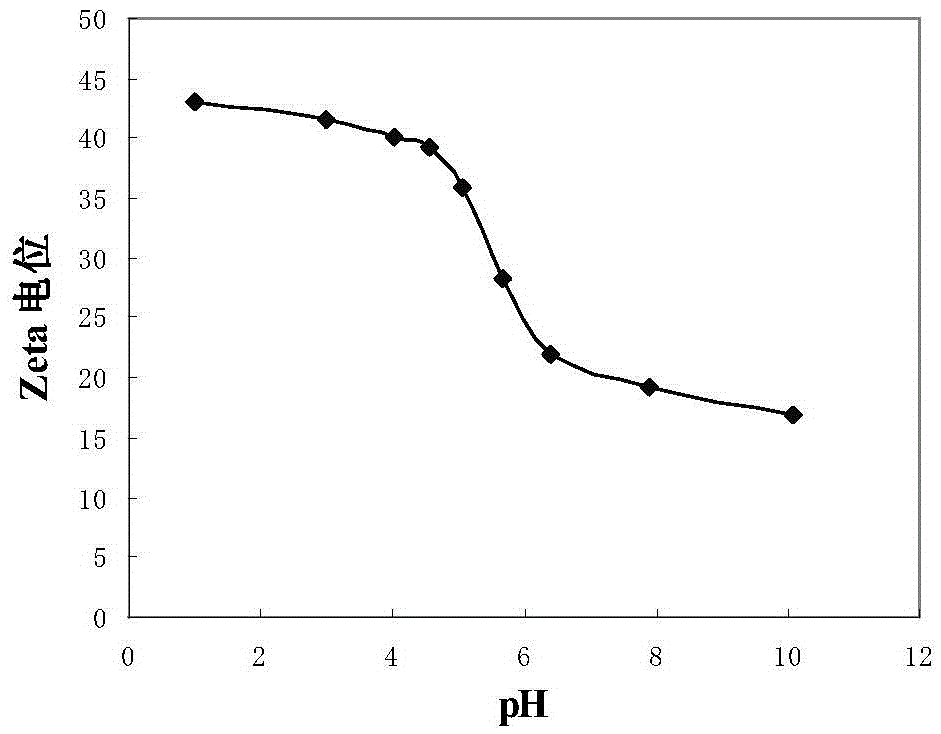

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com