Combined collector for separation of copper-cobalt sulfide ores

A technology of combining collector and cobalt sulfide ore is applied in the field of flotation reagents and the combined collector field of separating copper-cobalt sulfide ore. Cobalt content, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

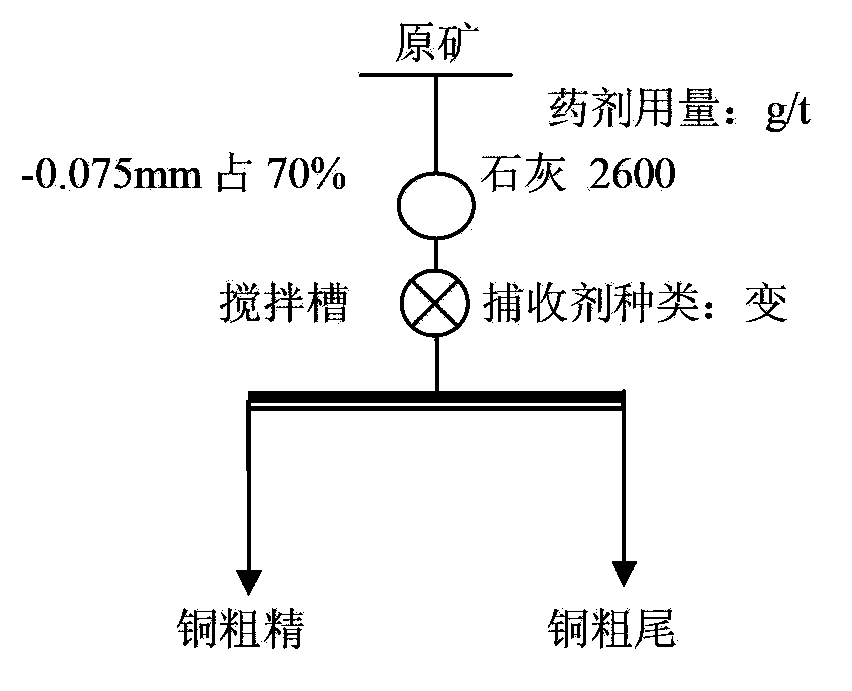

[0020] Preferential flotation of copper and cobalt from a copper-cobalt ore in a Baluba ore body abroad.

[0021] The ore composition of the copper-cobalt ore in the Baluba ore body is very complex and there are many types of minerals. The ore is mainly composed of copper, sulfur and iron, followed by cobalt, titanium, and trace amounts of bismuth, silver and other metal elements, of which copper and cobalt are beneficial components. Through the optical microscope identification of ore light, thin slices, and agglomerates, and the scanning electron microscope energy spectrum analysis of metal minerals in the light slices, it was found that the copper minerals in the ore are mainly chalcopyrite, and its content is 3.33%. Followed by bornite, its content is 0.11%, and a small amount of chalcocite, blue chalcocite, copper blue, etc.; cobalt minerals are mainly sulfur copper cobalt ore, its content is 0.08%, followed by a small amount of sulfur cobalt ore The sulfur mineral is py...

Embodiment 2

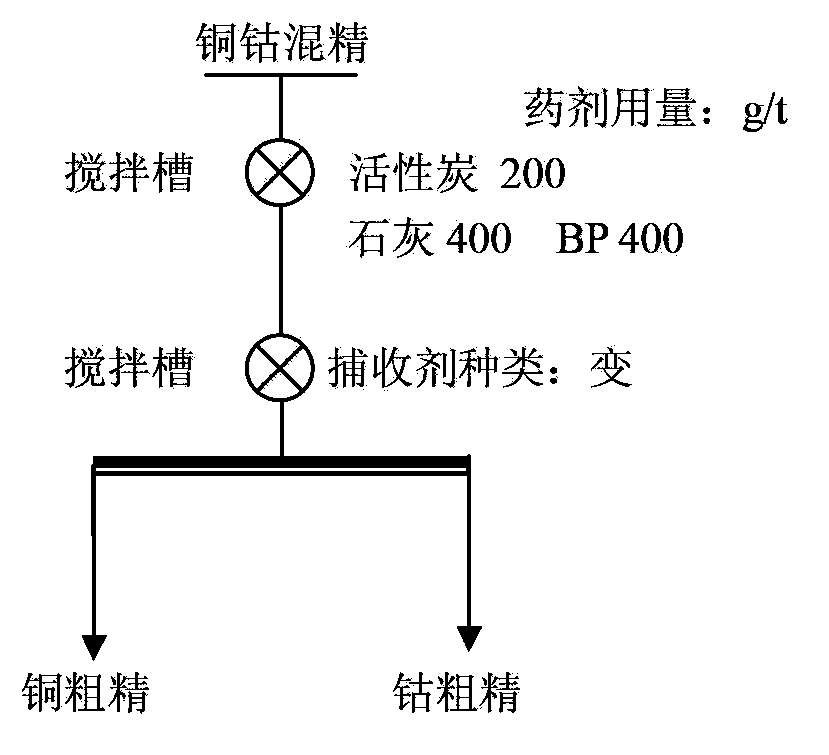

[0029] Copper-cobalt separation and flotation of copper-cobalt ore in a Baluba ore body abroad.

[0030] The properties of the ore are the same as those in Example 1. A mixed flotation process is applied to the ore to obtain a copper-cobalt mixed concentrate containing 20.2% copper and 1.08% cobalt. Use activated carbon to remove drugs (200g / t), lime (400g / t, pH 12.5) + BP (combined inhibitor 400g / t) to inhibit cobalt minerals, cobalt pyrite and pyrite, and use different collectors respectively Copper and cobalt separation. Process flow and process conditions see figure 2 , the test results are shown in Table 2.

[0031] Table 2 Collector type test results (%)

[0032]

[0033]

[0034] The test results show that the collection capacity for copper minerals is: butyl xanthate>collector provided by the present invention>isopropyl xanthate>ethyl thiocarbamate>ethyl xanthate. The collection ability of cobalt minerals is: butyl xanthate > isopropyl xanthate > ethyl xanth...

Embodiment 3

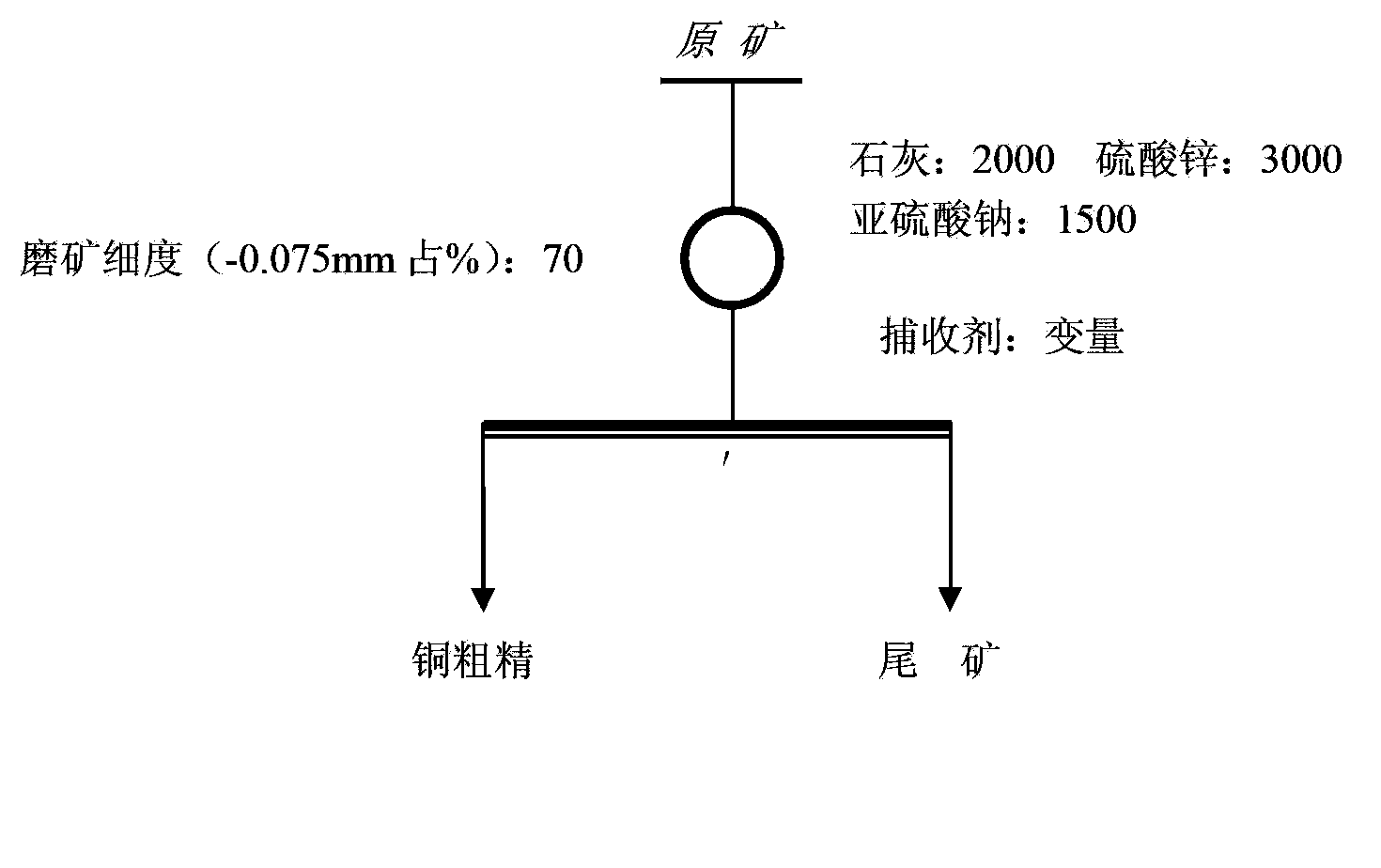

[0036] A copper-lead-zinc polymetallic sulfide ore in China is preferentially selected for copper.

[0037] For the test process and process conditions, see image 3 , the test results are shown in Table 3.

[0038] Table 3 Collector type test results (%)

[0039]

[0040]

[0041]Using the collector provided by the invention not only has a strong collection ability for copper minerals, but also has the lowest mutual content of lead and zinc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com