A kind of polymer water flooding water purifying agent and its preparation method and application

A polymer and water clearing agent technology, applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of increasing the difficulty of oil and water treatment, hindering the aggregation and coalescence of oil droplets, and increasing the viscosity of sewage, achieving excellent results The effect of clear water and degreasing, improving the hydrophilic/hydrophobic properties, and enhancing the destructive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

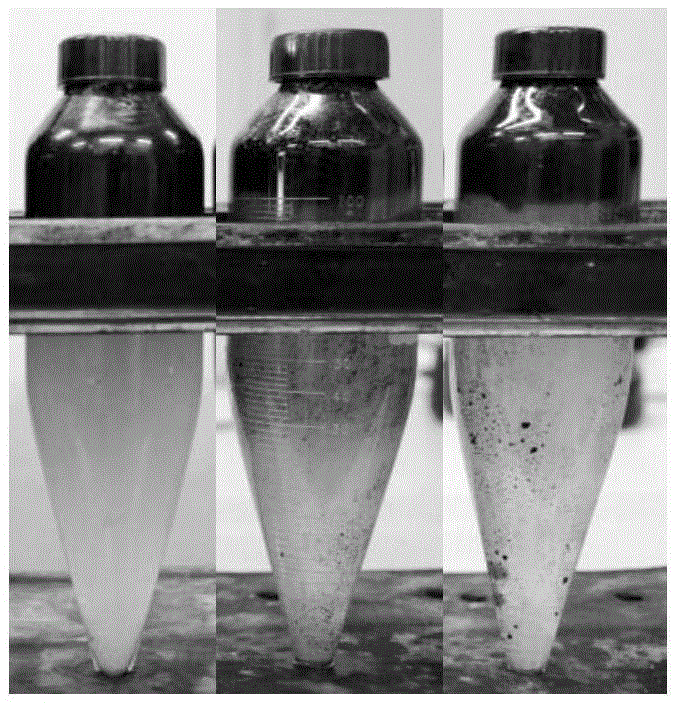

Image

Examples

Embodiment 1

[0047] Embodiment 1, the synthesis of water purifying agent CP-1

[0048] (1) Synthesis of α,α-bis(4-aminophenyl)-1-(3',5'-dimethyl-4'-sulfophenyl)methane

[0049] 1) Synthesis of aromatic diamines

[0050] Add 37.20g (0.40mol) of aniline and 70mL of distilled water to a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen port, and stir thoroughly under nitrogen protection. 50.00 mL of concentrated hydrochloric acid (37% by mass) was slowly added dropwise, and the system temperature was maintained at 40°C, and then 29.52 g (0.22 mol) of 3,5-dimethylbenzaldehyde was added in batches. After the system was vigorously stirred under reflux for 12h, the temperature of the reaction system was down to 50°C, and 34.60g of anhydrous potassium carbonate powder was added in batches under stirring until the system no longer produced bubbles. The solution was subjected to steam distillation, and a solid powder was obtained after suction filtration. Rinse the...

Embodiment 2

[0059] Embodiment 2, the synthesis of water purifying agent CP-2

[0060] (1) Synthesis of α,α-bis(4-amino-3,5-diethylphenyl)-1-(4'-methoxy-5'-sulfophenyl)methane

[0061] 1) Synthesis of aromatic diamines

[0062] Add 59.68g (0.40mol) of 2,6-diethylaniline and 120.00mL of distilled water to a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen port, and stir thoroughly under nitrogen protection. Slowly add 61.50mL of sulfuric acid solution (mass fraction 35%) dropwise, and maintain the system temperature at 30°C, then add 28.56g (0.21mol) of 4-methoxybenzaldehyde in batches. After the system was vigorously stirred for 6 h under reflux, the temperature of the reaction system was down to 50° C., and 36.90 g of sodium bicarbonate powder was added in batches under stirring until the system no longer produced bubbles. The solution was subjected to steam distillation, and a solid powder was obtained after suction filtration. Rinse the solid powder w...

Embodiment 3

[0071] Embodiment 3, the synthesis of water purifying agent CP-3

[0072] (1) α,α-bis(4-amino-3,5-dimethoxyphenyl)-1-(3',5'-dimethyl-4'-sulfophenyl)methane

[0073] 1) Synthesis of aromatic diamines

[0074] Add 61.28g (0.40mol) of 2,6-dimethoxyaniline and 135.00mL of distilled water to a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen port, and stir thoroughly under nitrogen protection. 40.50 mL of concentrated hydrochloric acid (37% by mass) was slowly added dropwise, the system temperature was maintained at 35°C, and then 28.14 g (0.21 mol) of 3,5-dimethylbenzaldehyde was added in batches. After the system was vigorously stirred for 6 h under reflux, the temperature of the reaction system was reduced to 50° C., and 16.40 g of sodium hydroxide powder was added in batches under stirring. The solution was subjected to steam distillation, and a solid powder was obtained after suction filtration. Rinse the solid powder with hot water, recryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com