Chemical mechanical polishing method

A chemical machinery, polishing liquid technology, applied in polishing compositions containing abrasives, grinding machine tools, grinding devices, etc., to achieve the effects of reducing content, reducing use costs, and controlling the polishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

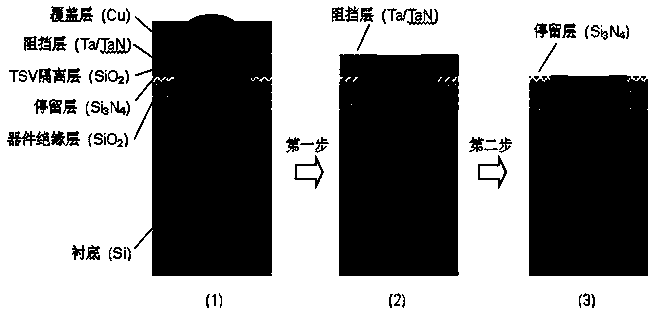

Method used

Image

Examples

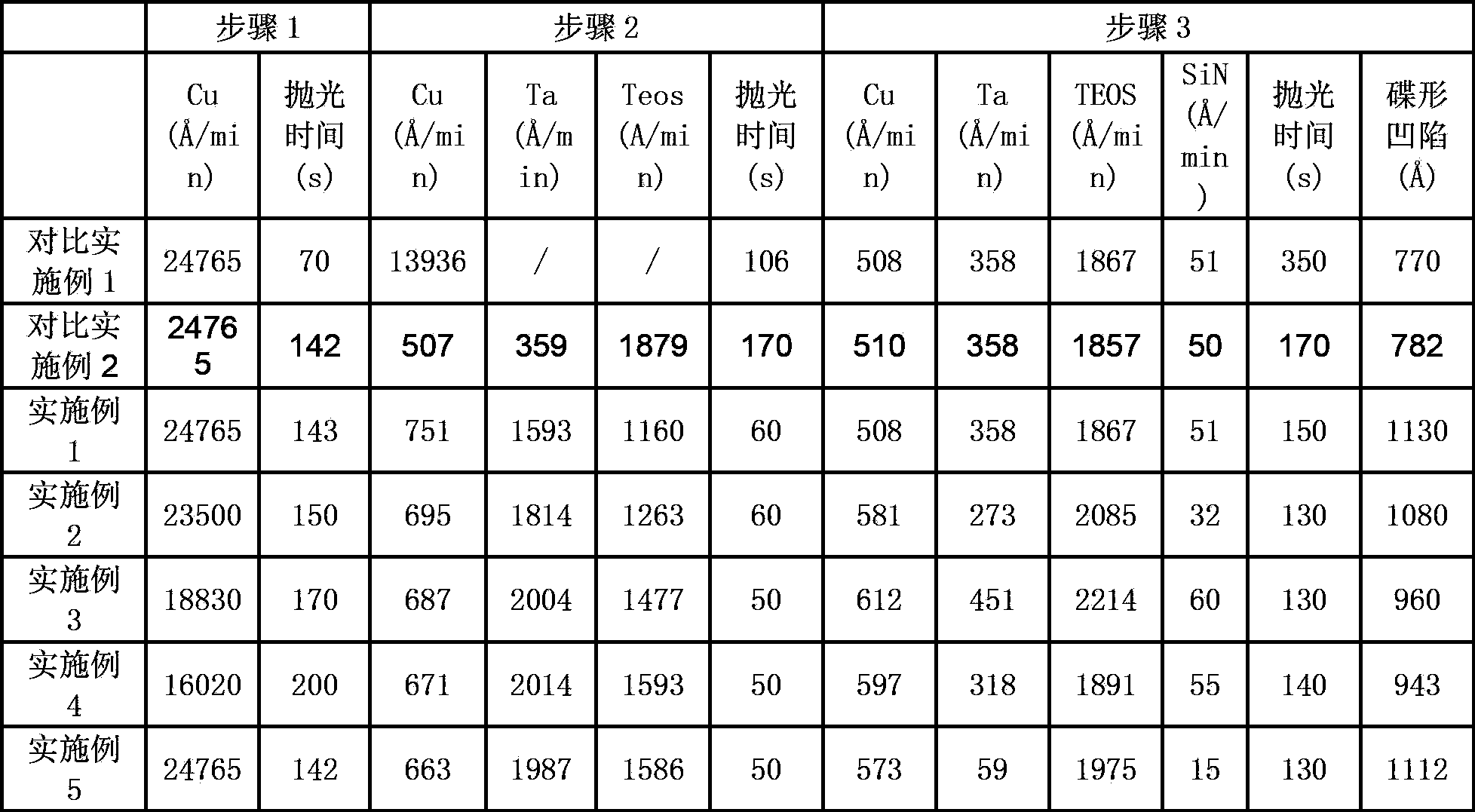

Embodiment 1

[0031] Embodiment 1 step-by-step chemical mechanical polishing method

[0032] Copper polishing liquid: TSV-A21 copper polishing liquid sold in Anji Market;

[0033] Barrier layer polishing solution: 5wt% silicon dioxide, benzotriazole as corrosion inhibitor, oxalic acid as complexing agent, hydrogen peroxide as oxidizing agent, water as the balance, pH=2.0;

[0034] Dielectric layer polishing liquid: 15wt% silicon dioxide, corrosion inhibitor is benzotriazole, complexing agent is oxalic acid, silicon nitride inhibitor is 0.1wt% sodium methylene dinaphthalene sulfonate, oxidant is hydrogen peroxide, Water is the balance, pH=3.0

[0035] 1. Use TSV-A21 copper polishing liquid on the first polishing disc, the polishing conditions are: the polishing pad is IC pad, the down pressure is 3.0psi, the rotational speed is polishing disc / polishing head=93 / 87rpm, and the flow rate of polishing liquid is 150ml / min, the polishing time is controlled by the end point control system.

[0...

Embodiment 2

[0038] Embodiment 2 step-by-step chemical mechanical polishing method

[0039] Copper polishing liquid: TSV-A21 copper polishing liquid sold in Anji

[0040] Barrier layer polishing solution: 8wt% silicon dioxide, corrosion inhibitor is methyl benzotriazole, complexing agent is citric acid, oxidizing agent is hydrogen peroxide, water is the balance, pH=3.0

[0041]Dielectric layer polishing liquid: 25wt% silicon dioxide, the corrosion inhibitor is tolyl benzotriazole, the complexing agent is citric acid, the silicon nitride inhibitor is 0.3wt% sodium methylnaphthalenesulfonate formaldehyde condensation polymer, Oxidant is hydrogen peroxide, water is the balance, pH=3.0

[0042] 1. Use TSV-A21 copper polishing liquid on the first polishing disc, the polishing conditions are: the polishing pad is IC pad, the down pressure is 3.0psi, the rotation speed is polishing disc / polishing head = 55 / 50rpm, and the flow rate of polishing liquid is 150ml / min, the polishing time is control...

Embodiment 3

[0045] Embodiment 3 step-by-step chemical mechanical polishing method

[0046] Copper polishing liquid: TSV-A21 copper polishing liquid sold in Anji

[0047] Barrier layer polishing solution: 10%wt silicon dioxide, 1,2,4-triazole as corrosion inhibitor, malonic acid as complexing agent, hydrogen peroxide as oxidizing agent, water as balance, pH=4.0

[0048] Dielectric layer polishing solution: 30wt% silicon dioxide, 1,2,4-triazole as a corrosion inhibitor, malonic acid as a complexing agent, and 0.5wt% polycondensation of benzylnaphthalenesulfonic acid formaldehyde as a silicon nitride inhibitor The oxidizing agent is hydrogen peroxide, the balance is water, pH=4

[0049] 1. Use TSV-A21 copper polishing liquid on the first polishing disc, the polishing conditions are: the polishing pad is IC pad, the down pressure is 2.0psi, the rotational speed is polishing disc / polishing head=115 / 110rpm, and the flow rate of polishing liquid is 150ml / min, the polishing time is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com