Preparation method for N-shaped back-junction solar cell

A solar cell, N-type technology, applied in the field of solar cells, can solve problems such as the impact of silicon chip minority carrier life, complex cell preparation process, and affect efficiency, and achieve the effect of improving photoelectric conversion efficiency, suitable for popularization and application, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

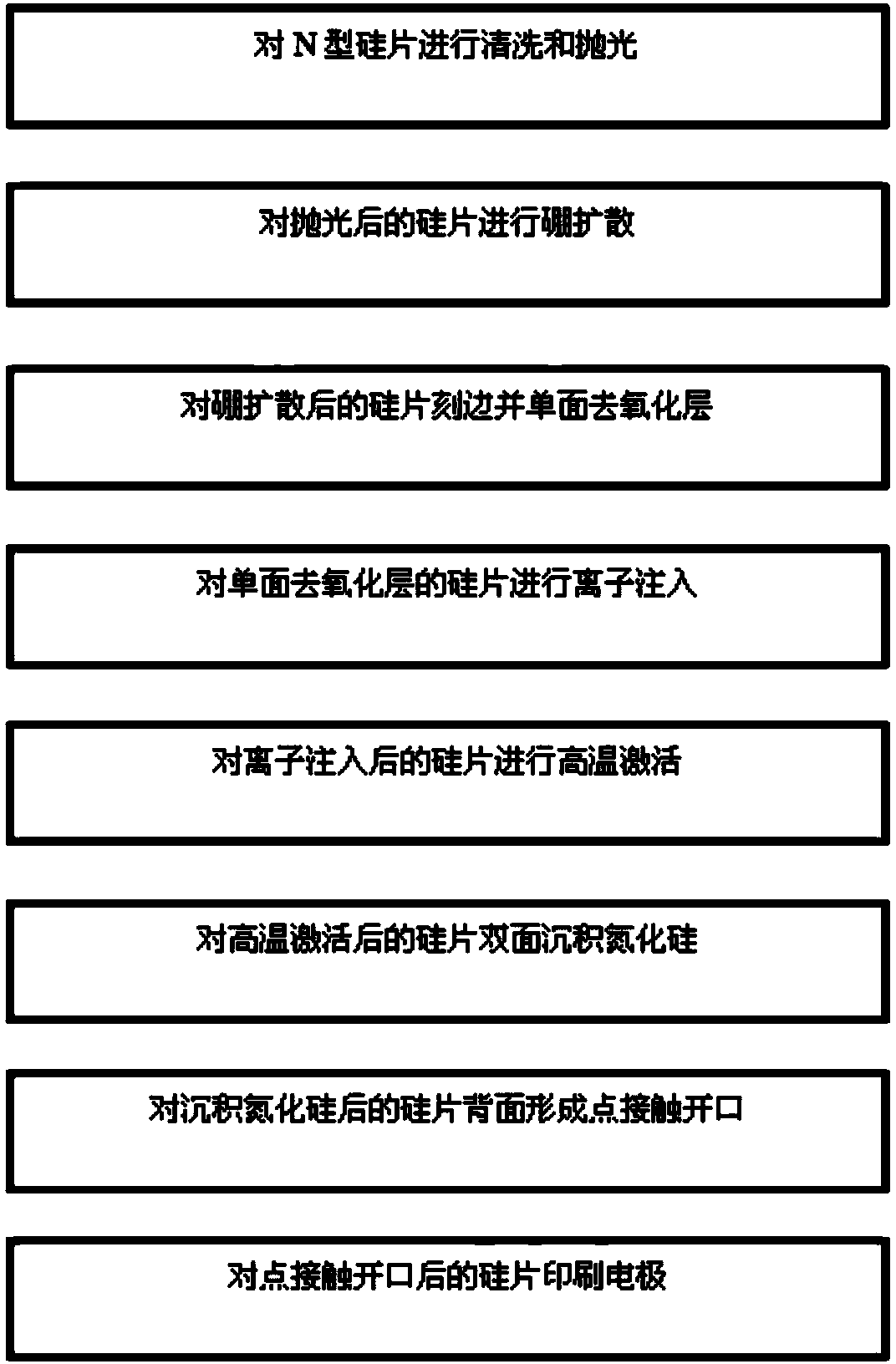

[0030] see figure 1 Shown, a kind of preparation method of N-type back junction solar cell comprises the steps:

[0031] (1) Cleaning; double-sided polishing of the back surface and front surface of the N-type silicon wafer; polishing can be carried out in pure tetramethylammonium hydroxide solution;

[0032] (2) Carrying out boron diffusion to the above-mentioned N-type silicon wafer;

[0033] The boron diffusion adopts the boron tribromide liquid source diffusion method, and the boron diffusion uses boron tribromide as the source high-temperature diffusion in a tube furnace, which can be inserted into a single piece or double pieces;

[0034] First deposit boron tribromide with oxygen at 950°C for 30 minutes, then advance without power supply for 30 minutes under an oxygen atmosphere, then cool down to 850°C and oxidize for 40 minutes, and grow an oxide layer on the front and back surfaces of the silicon wafer; The thickness of the oxide layer is at least 20 nanometers;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com