Method for preparing rapeseed peptide through synergistic fermentation of lysozyme and rapeseed dregs

A technology of synergistic fermentation and rapeseed meal, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of low yield of rapeseed peptides, and achieve a wide range of raw material sources, reduced costs and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

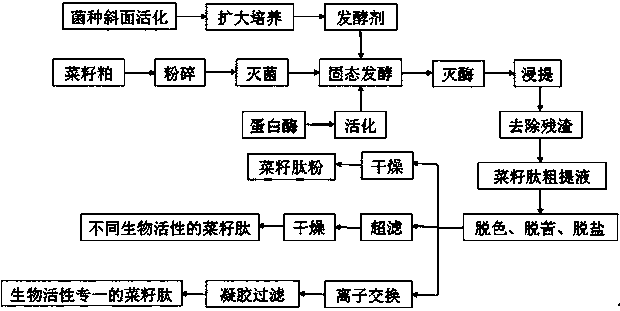

Image

Examples

Embodiment 1

[0041] Production of rapeseed peptide by solid-state fermentation of rapeseed meal with mixed bacteria and enzymes

[0042] Preparation of Bacillus subtilis starter:

[0043] Slant medium: beef extract 0.3g; peptone 1.0g; NaCl 0.5g; nutrient agar 2.0g; tap water 100mL; pH 7.2~7.4.

[0044] Seed medium: beef extract 0.3g; peptone 1.0g; NaCl 0.5g; tap water 100mL; pH 7.2~7.4.

[0045] Sterile nutrient solution: glucose 5.0g; KH 2 PO 4 3.0g; sterile water 1000mL; pH 7.0.

[0046] Preparation of starter: Pick two rings of Bacillus subtilis from the activated strain preservation slant and inoculate it in the seed medium, seal it with 8 layers of gauze, culture it on a shaker at 35°C, 120r / min for 24 hours, to increase the concentration of bacteria. reach 10 8 individual / mL. Dilute the seed solution with sterile nutrient solution to prepare a bacterial cell concentration of 3×10 7 Individual / mL Bacillus subtilis starter.

[0047] Preparation of Mucor actinosa starter:

[00...

Embodiment 2

[0057] Synchronous solid-state fermentation of rapeseed meal with mixed bacteria and enzymes to produce rapeseed peptide

[0058] Preparation of Bacillus subtilis starter:

[0059] Slant medium: beef extract 0.3g; peptone 1.0g; NaCl 0.5g; nutrient agar 2.0g; tap water 100mL; pH 7.2~7.4.

[0060] Seed medium: beef extract 0.3g; peptone 1.0g; NaCl 0.5g; tap water 100mL; pH 7.2~7.4.

[0061] Sterile nutrient solution: glucose 5.0g; KH 2 PO 4 3.6g; sterile water 1000mL; pH 6.5.

[0062] Preparation of starter: Pick two rings of Bacillus subtilis from the activated strain preservation slant and inoculate it in the seed medium, seal it with 8 layers of gauze, culture it on a shaker at 35°C, 120r / min for 24 hours, to increase the concentration of bacteria. reach 10 8 individual / mL. Dilute the seed solution with sterile nutrient solution to prepare a bacterial cell concentration of 3×10 7 Individual / mL Bacillus subtilis starter.

[0063] Preparation of Mucor actinosa starter: ...

Embodiment 3

[0073] Synchronous solid-state fermentation of rapeseed meal with mixed bacteria and enzymes to produce rapeseed active peptide

[0074] Difference with embodiment 2 is, carry out purification according to the following method:

[0075] Rapeseed peptide crude extract was passed through activated carbon column, desalting column (HiPrep TM 26 / 10, flow rate 30mL / min, room temperature) after decolorization, debittering, and desalination, then ultrafiltration was carried out through ultrafiltration membranes with molecular weight cut-offs of 30kDa, 10kDa, 5kDa, 3kDa and 1kDa respectively, and the filtrates with different molecular weight cut-offs were collected. Five component rapeseed peptide powders with different biological activities were obtained by freeze-drying. The protein content of the rapeseed peptide is 90% (dry basis, N×6.25), and the peptide content with a molecular weight of 1kDa-5kDa is 70%.

[0076] The components with a molecular weight in the range of 1kDa~3kD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com