Preparation method of mortar concrete waterproof agent

The technology of mortar concrete and concrete shrinkage reducing agent is applied in the field of preparation of concrete waterproofing agent. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

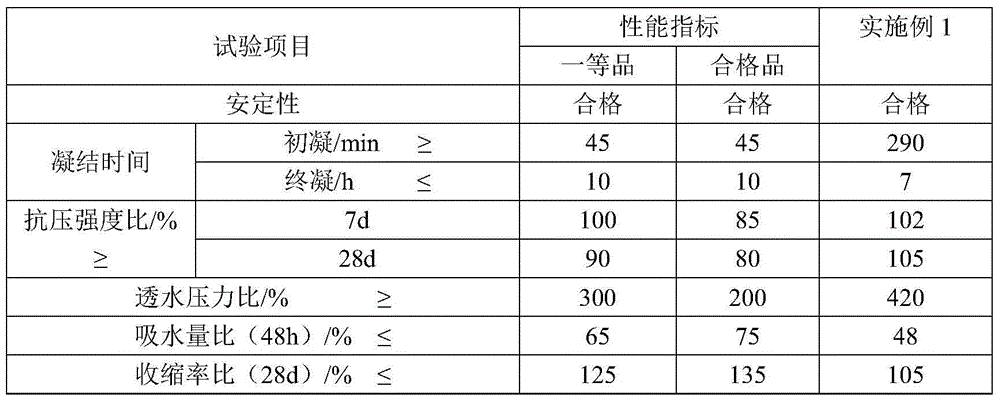

Embodiment 1

[0028]At room temperature, add dropwise a mixture of 60 parts of methyl methacrylate, 40 parts of LMA and 50 parts of oleic acid to 100 parts of water containing 10 parts of SN-10 and 20 parts of PZ-141 while stirring, and within 30 minutes After the dropwise addition, the monomer pre-emulsion is obtained; first, dissolve 5 parts of ammonium persulfate in 20 parts of water for later use, then add 5 parts of K90 into 390 parts of water, stir and raise the temperature to 60°C to dissolve it into a clear liquid, and then dissolve it in 2 hours Add 50% ammonium persulfate solution and all the monomer pre-emulsion evenly under internal stirring conditions at the same time, and then add the remaining ammonium persulfate solution and 200 parts of Z-6518 and 100 A mixture of DY-V401 (viscosity 1500cs), after dripping, keep it warm for 1 hour, cool down to 50°C, filter and discharge to obtain an emulsion with a silicone core-shell structure, with a particle size of 160nm.

[0029] Unde...

Embodiment 2

[0031] At room temperature, add dropwise a mixture of 220 parts of methyl acrylate, 110 parts of SMA and 70 parts of linoleic acid to 110 parts of water containing 7.5 parts of SN-15 and 7.5 parts of PAM-200 while stirring, and drop it within 30 minutes After the addition, the monomer pre-emulsion is obtained; first dissolve 10 parts of sodium persulfate in 55 parts of water for later use, then add 10 parts of polyvinyl alcohol 1799 into 200 parts of water and stir to raise the temperature to 80°C to dissolve it into a clear liquid, then Add 50% sodium persulfate solution and all the monomer pre-emulsion evenly dropwise within 1 hour under stirring condition, and then add the remaining sodium persulfate solution and 100 parts of Z-6036 evenly within 3 hours under stirring condition Mix it with 100 parts of DY-V401 (viscosity 5000cs), keep it warm for 1 hour after dropping, cool down to 50°C, filter and discharge to obtain a silicone core-shell emulsion with a particle size of 2...

Embodiment 3

[0034] At room temperature, add dropwise a mixture of 130 parts of acrylonitrile, 70 parts of butyl acrylate and 70 parts of palmitoleic acid to 130 parts of water containing 6.7 parts of SN-20 and 3.3 parts of COPS-1 while stirring, and within 30 minutes After the dropwise addition, the monomer pre-emulsion is obtained; first, dissolve 8 parts of potassium persulfate in 40 parts of water for later use, then add 5 parts of sodium polyacrylate into 236.5 parts of water, stir and raise the temperature to 70°C to dissolve it into a clear liquid, and then Add 50% potassium persulfate solution and all the monomer pre-emulsion uniformly dropwise within 2 hours under stirring conditions, and then drop the remaining potassium persulfate solution and 100 parts of Z-6518 uniformly within 2 hours under stirring conditions Mix with 200 parts of DY-V401 (viscosity 300cs), keep it warm for 2 hours after dropping, cool down to 50°C, filter and discharge to obtain an emulsion with a silicone c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com