Synthesis method of nano-molybdenum carbide

A synthesis method and technology of molybdenum carbide, applied in the direction of carbides, tungsten/molybdenum carbides, etc., can solve the problems of complex precursor preparation, large product particles, and insufficient reaction, and achieve excellent catalytic performance, small particles, and process The effect of low conditional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 0.1g of molybdenum trioxide was dissolved in 10mL of hydrogen peroxide with a mass fraction of 30wt%, placed in a water bath at 60°C and stirred for 2 hours;

[0029] (2) Dissolve 10g of glucose in 100mL of water;

[0030] (3) After mixing the two solutions in (1) and (2), place them in a water bath at 40°C and stir for 12 hours;

[0031] (4) The solution obtained in (3) was put into a 150mL autoclave, and hydrothermally treated at 180° C. for 6 hours to obtain a black product;

[0032] (5) After cooling the black product obtained in (4), wash it three times with deionized water, filter it, place it in an oven and dry it at 80°C for 24 hours until dry;

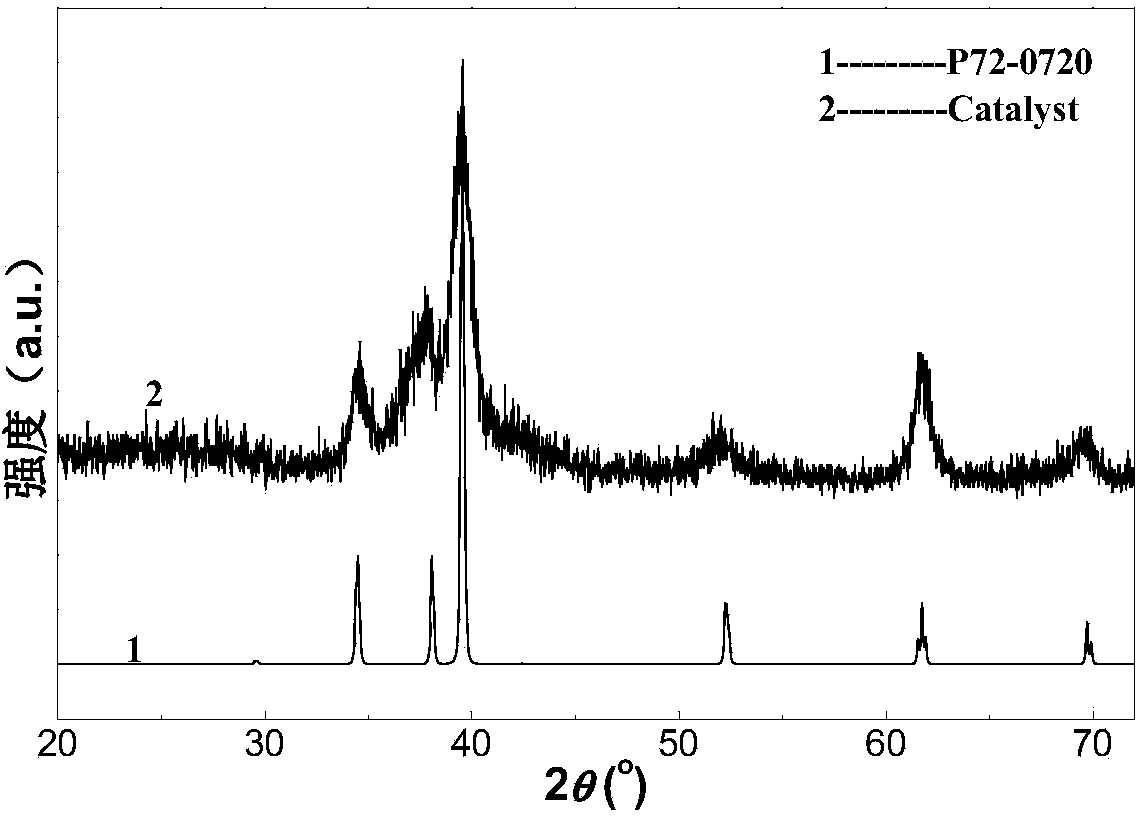

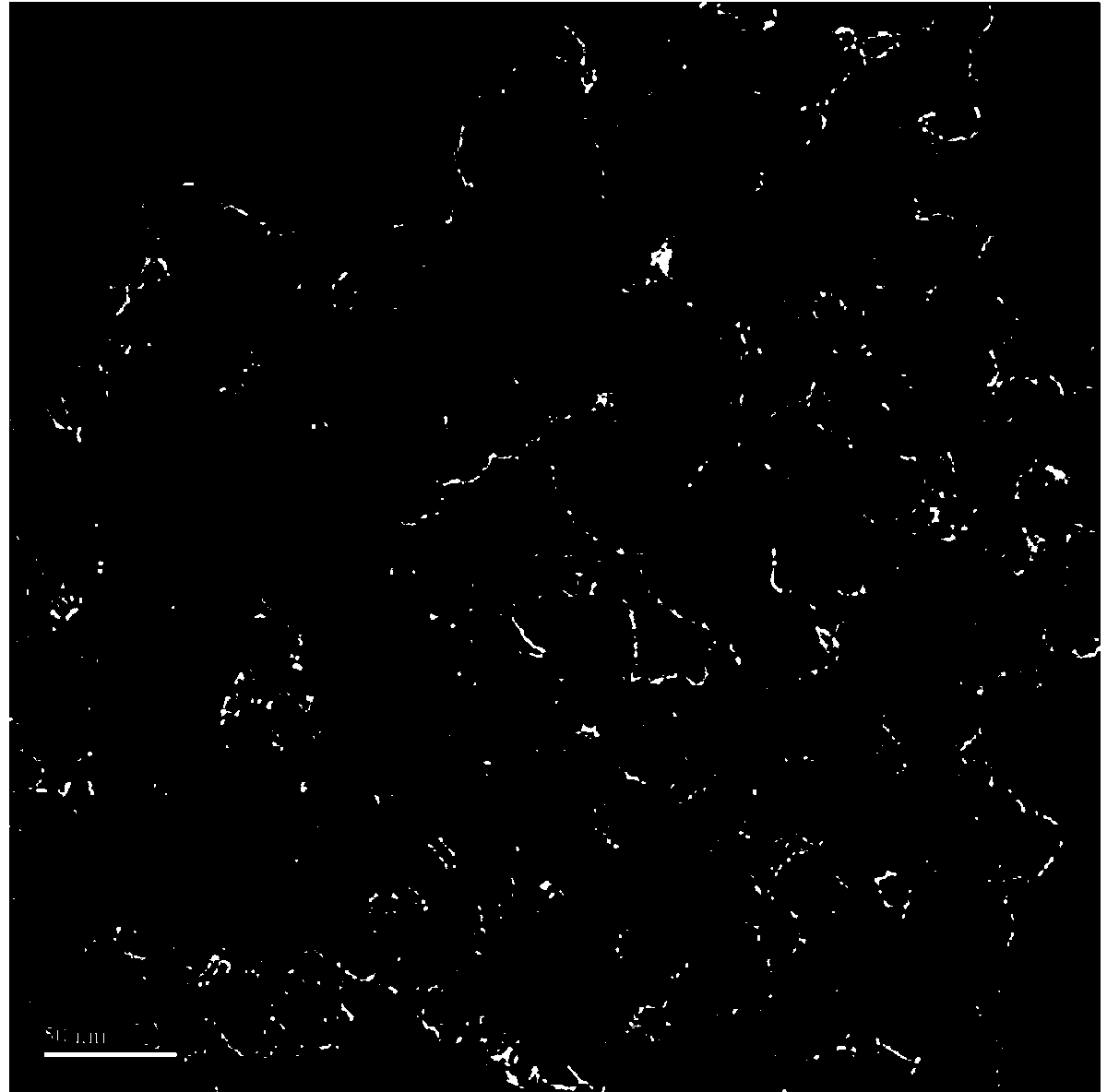

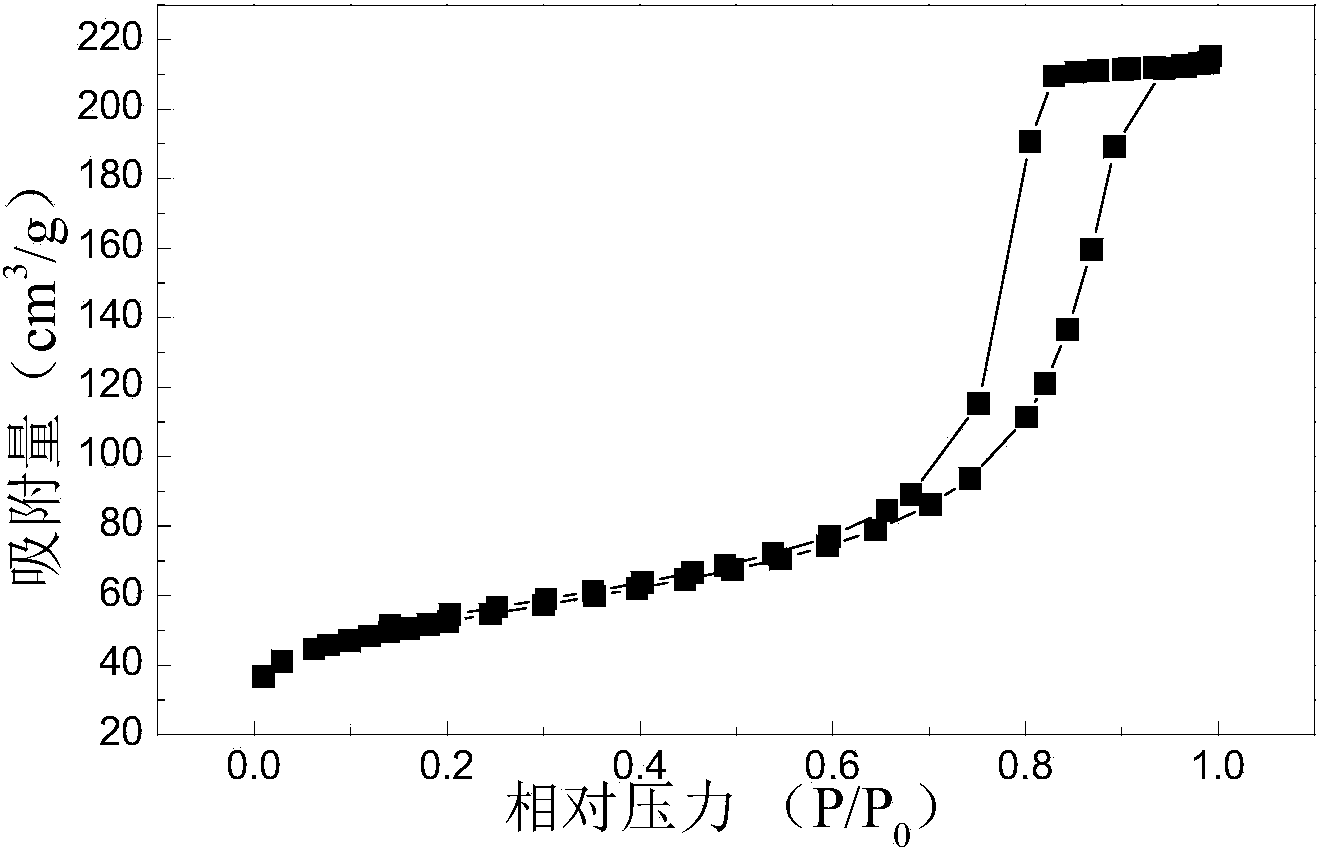

[0033] (6) Roast the product obtained in (5) at 700°C for 12 hours under an argon atmosphere of 30mL / min / gcat, and replace it with 2.0vol.%O after the temperature drops to 30°C 2 / Ar passivation gas, passivation treatment 12h, flow rate 5mL / min / gcat. The obtained sample was designated as MoC-1. Its phase paramet...

Embodiment 2

[0035] (1) 2g of ammonium molybdate was dissolved in 20mL of hydrogen peroxide with a mass fraction of 30wt%, placed in a water bath at 50°C and stirred for 2 hours;

[0036] (2) Dissolve 25g of sucrose in 100mL of water;

[0037] (3) After mixing the two solutions in (1) and (2), place them in a water bath at 40°C and stir for 12 hours;

[0038] (4) The solution obtained in (3) was put into a 150mL autoclave, and hydrothermally treated at 170° C. for 6 hours to obtain a black product;

[0039] (5) After cooling the black product obtained in (4), wash it three times with deionized water, filter it, place it in an oven and dry it at 80°C for 24 hours until dry;

[0040] (6) Roast the product obtained in (5) at 700°C for 12 hours under an argon atmosphere of 30mL / min / gcat, and replace it with 2.0vol.%O after the temperature drops to 30°C 2 / Ar passivation gas, passivation treatment 12h, flow rate 10mL / min / gcat. The resulting sample was designated MoC-2. Its phase parameters ...

Embodiment 3

[0042] (1) 2g of sodium molybdate was dissolved in 20mL of hydrogen peroxide with a mass fraction of 30wt%, placed in a water bath at 70°C and stirred for 2 hours;

[0043] (2) Dissolve 30g of maltose in 100mL of water;

[0044] (3) After mixing the two solutions in (1) and (2), place them in a water bath at 40°C and stir for 12 hours;

[0045] (4) The solution obtained in (3) was put into a 150mL autoclave, and hydrothermally treated at 190° C. for 6 hours to obtain a black product;

[0046](5) After cooling the black product obtained in (4), wash it three times with deionized water, filter it, place it in an oven and dry it at 80°C for 24 hours until dry;

[0047] (6) Roast the product obtained in (5) at 700°C for 12 hours under an argon atmosphere of 30mL / min / gcat, and replace it with 2.0vol.%O after the temperature drops to 30°C 2 / Ar passivation gas, passivation treatment for 12 hours, the flow rate is 15mL / min / gcat. The resulting sample was designated as MoC-3. Its p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com