Air conditioner cleaning agent and manufacturing method thereof

A cleaning agent and air conditioner technology, applied in the field of daily necessities cleaning, can solve the problems of increasing system operation and maintenance costs, shortening the service life of equipment, and scrapping the main engine, and achieves the effect of thorough cleaning, low cost and little environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

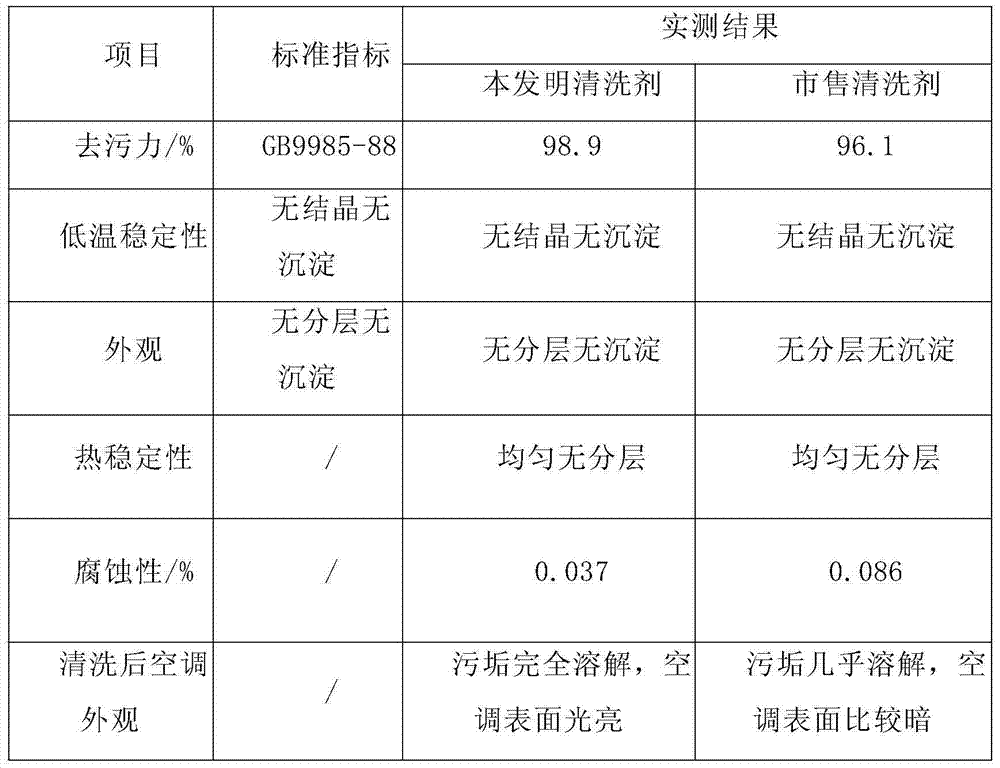

Examples

Embodiment 1

[0018] A kind of air-conditioning cleaning agent, comprises the raw material of following percentage by weight: dodecyl trimethyl ammonium chloride 2%, nonylphenol polyoxyethylene ether 2%, dipropylene glycol dimethyl ether 15%, propylene carbonate 2%, Cyclodextrin 2%, phosphomolybdic acid 0.5%, corrosion inhibitor 0.5%, sodium pyrophosphate 0.2%, sodium carbonate 2%, sodium bicarbonate 2%, sodium chloride 2%, edetate disodium 0.6% , 0.2% essence, and the balance is deionized water.

[0019] A preparation method of an air conditioner cleaning agent, comprising the following steps:

[0020] (1) According to the percentage by weight, weigh sodium pyrophosphate and add deionized water to pre-dissolve it. After it is fully dissolved, add sodium carbonate and sodium bicarbonate. Stir evenly until it is completely dissolved. This liquid is called liquid A and placed for use. ;

[0021] (2) Add dodecyltrimethylammonium chloride, nonylphenol polyoxyethylene ether, propylene carbonat...

Embodiment 2

[0024] A kind of air conditioner cleaning agent, comprises the raw material of following percentage by weight: dodecyltrimethylammonium chloride 3%, fatty alcohol polyoxyethylene ether 3%, isopropanol 12%, propylene carbonate 3%, cyclodextrin 3%, dipropylene glycol monobutyl ether 3%, phosphomolybdic acid 1%, corrosion inhibitor 1%, sodium pyrophosphate 0.3%, sodium carbonate 3%, sodium bicarbonate 3%, sodium chloride 3%, ethylenediaminetetra Disodium acetate 0.6%, essence 0.3%, the balance is deionized water.

[0025] A preparation method of an air conditioner cleaning agent, comprising the following steps:

[0026] (1) According to the percentage by weight, weigh sodium pyrophosphate and add deionized water to pre-dissolve it. After it is fully dissolved, add sodium carbonate and sodium bicarbonate. Stir evenly until it is completely dissolved. This liquid is called liquid A and placed for use. ;

[0027] (2) Add surfactant, co-solvent, cyclodextrin, corrosion inhibitor an...

Embodiment 3

[0030] An air conditioner cleaning agent, comprising the following raw materials in weight percentage: 4% dodecyltrimethylammonium chloride, 4% nonylphenol polyoxyethylene ether, 10% isopropyl alcohol, 3% dipropylene glycol monobutyl ether, Cyclodextrin 4%, phosphomolybdic acid 0.7%, corrosion inhibitor 1.5%, sodium pyrophosphate 0.3%, sodium carbonate 3%, sodium bicarbonate 3%, sodium chloride 3%, edetate disodium 0.6% , 0.3% essence, and the balance is deionized water.

[0031] A preparation method of an air conditioner cleaning agent, comprising the following steps:

[0032] (1) According to the percentage by weight, weigh sodium pyrophosphate and add deionized water to pre-dissolve it. After it is fully dissolved, add sodium carbonate and sodium bicarbonate. Stir evenly until it is completely dissolved. This liquid is called liquid A and placed for use. ;

[0033] (2) Add surfactants, cosolvents, cyclodextrins, corrosion inhibitors and fungicides into the environment-fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com