Apparatus and method for inhibiting air-conditioning cooling water legionella

A technology of cooling water and Legionella, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems of heavy workload, excessive dirt, waste of water resources, etc., and achieve small footprint, simple management, and energy saving consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

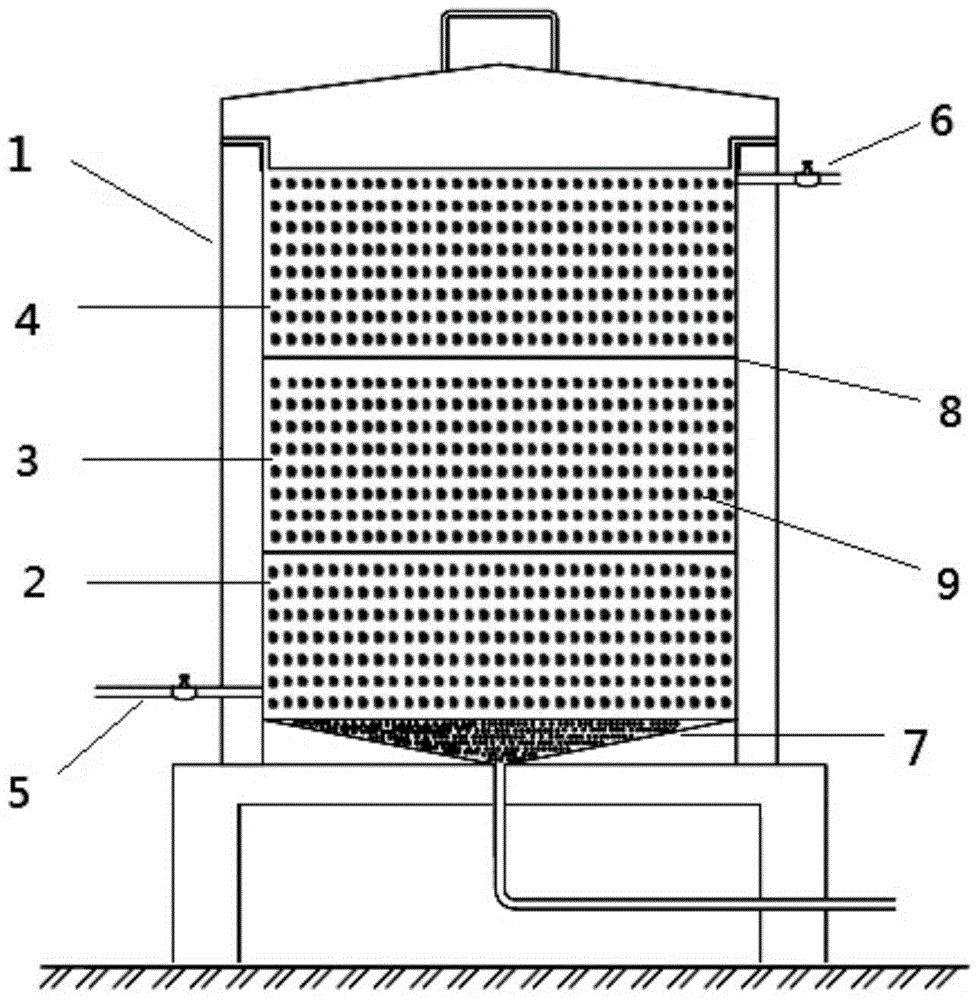

[0050] (1) The process parameters are as follows:

[0051] The volume ratio of the 1# zone, 2# zone and 3# zone of the device for inhibiting legionella in the cooling water of the air conditioner is 4:3:1.

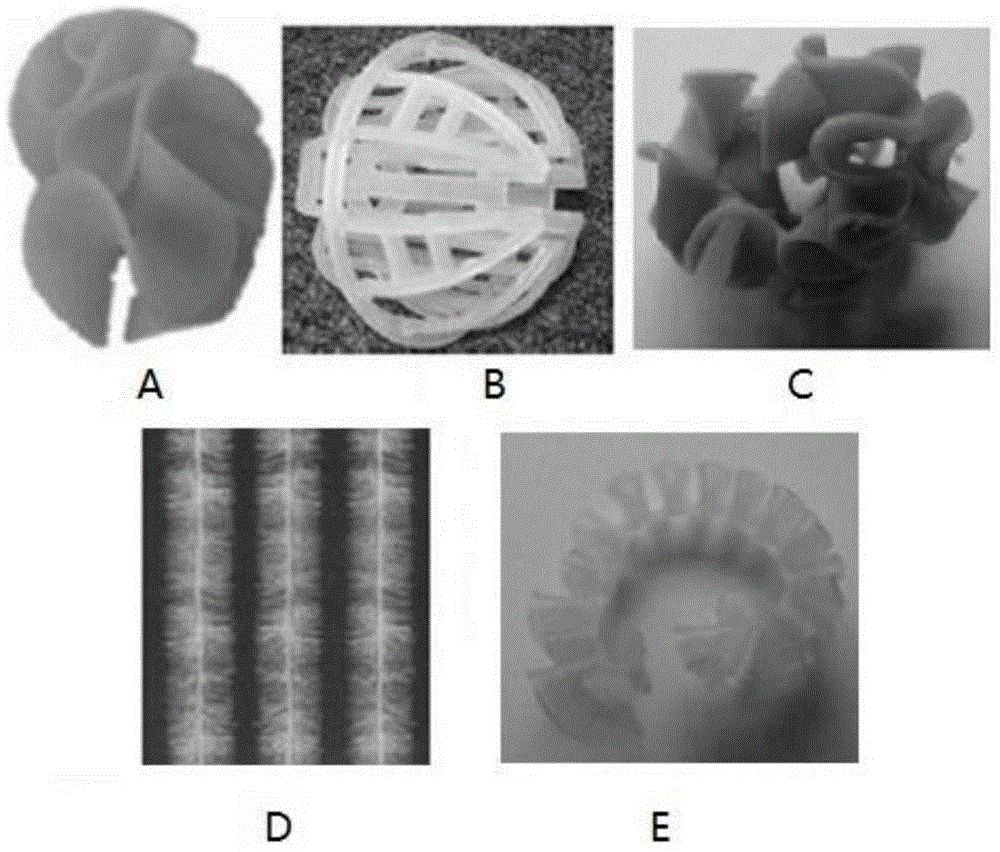

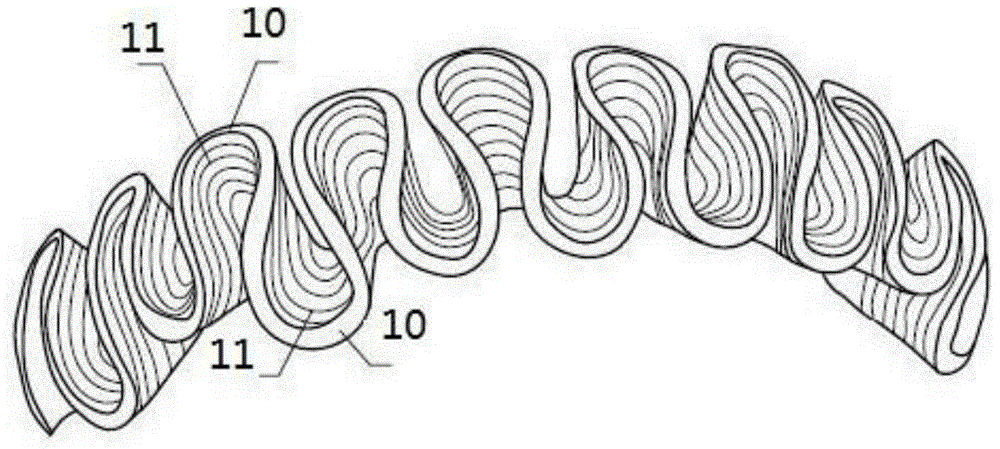

[0052] 1# area: the volume ratio of petal-shaped filler, bio-suspended ball filler and threaded ditch spherical filler = 4:1:4, and the diameter of the air bubbles produced by aeration is 4mm;

[0053] 2# area: the volume ratio of petal-shaped filler, YDT elastic three-dimensional filler and spiral strip-shaped filler = 1:5:3, and the diameter of the air bubbles generated by aeration is 1mm;

[0054] Zone 3: The volume ratio of threaded ditch spherical packing to spiral strip packing is 6:1, and the diameter of air bubbles produced by aeration is 1mm.

[0055] The baffle aperture of 1# zone and 2# zone is 3mm;

[0056] The aperture of the baffle plate in the 2# area and the 3# area is 1mm.

[0057] Packing volume: 1.5m in total 3 .

[0058] Processing temperature: 28....

Embodiment 2

[0067] (1) The process parameters are as follows:

[0068] The volume ratio of the 1# zone, 2# zone and 3# zone of the device for inhibiting Legionella in the cooling water of the air conditioner is 5:4:1.

[0069] 1# area: the volume ratio of petal-shaped filler, bio-suspended ball filler and threaded ditch spherical filler = 2:1:6, and the diameter of the air bubbles produced by aeration is 3mm;

[0070] 2# area: the volume ratio of petal-shaped filler, YDT elastic three-dimensional filler and spiral strip-shaped filler = 1:4:2, and the diameter of the air bubbles generated by aeration is 0.8mm;

[0071] Area 3: The volume ratio of threaded ditch spherical filler to spiral strip filler is 8:1, and the diameter of air bubbles produced by aeration is 0.5mm.

[0072] The baffle aperture of 1# zone and 2# zone is 4mm;

[0073] The aperture of the baffle plate in the 2# area and the 3# area is 0.5mm.

[0074] Packing volume: a total of 2m 3 .

[0075] Processing temperature:...

Embodiment 3

[0084] (1) The process parameters are as follows:

[0085] The volume ratio of the 1# zone, 2# zone and 3# zone of the device for inhibiting Legionella in air-conditioning cooling water is 3:2:1.

[0086] 1# area: the volume ratio of petal-shaped filler, bio-suspended ball filler and threaded ditch spherical filler = 3:1:7, and the diameter of the air bubbles produced by aeration is 5mm;

[0087] 2# area: the volume ratio of petal-shaped filler, YDT elastic three-dimensional filler and spiral strip-shaped filler = 1:6:3, and the diameter of the air bubbles generated by aeration is 1.5mm;

[0088] Area 3: The volume ratio of threaded ditch spherical packing to spiral strip packing is 7:1, and the diameter of air bubbles produced by aeration is 0.8mm.

[0089] The baffle aperture of 1# zone and 2# zone is 5mm;

[0090] The aperture of the baffle plate in the 2# area and the 3# area is 0.1mm.

[0091] Packing volume: 1.5m in total 3 .

[0092] Processing temperature: 32.6°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com