A kind of non-sintering fast hanging film biological filler and preparation method thereof

A non-sintering and membrane biotechnology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of high energy consumption in the preparation process, poor effluent quality, and long film-hanging time, etc., to achieve Large specific surface area, extended service life and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

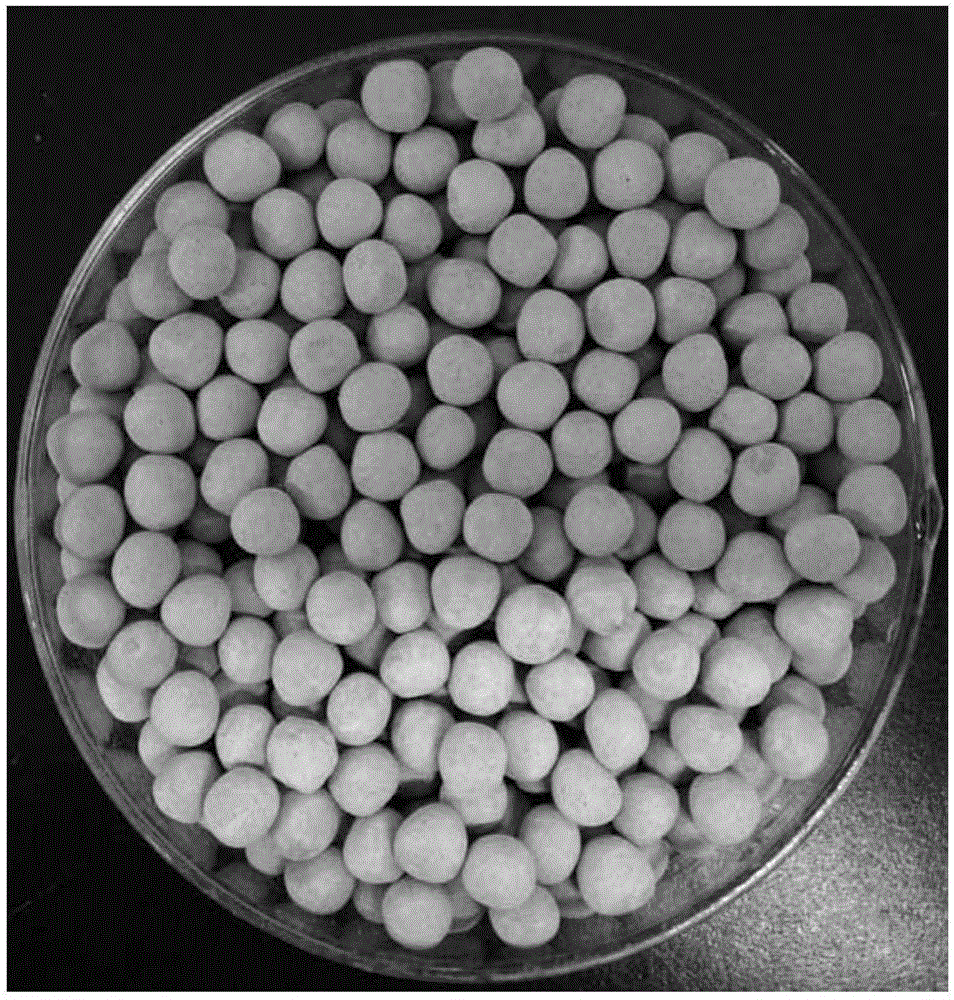

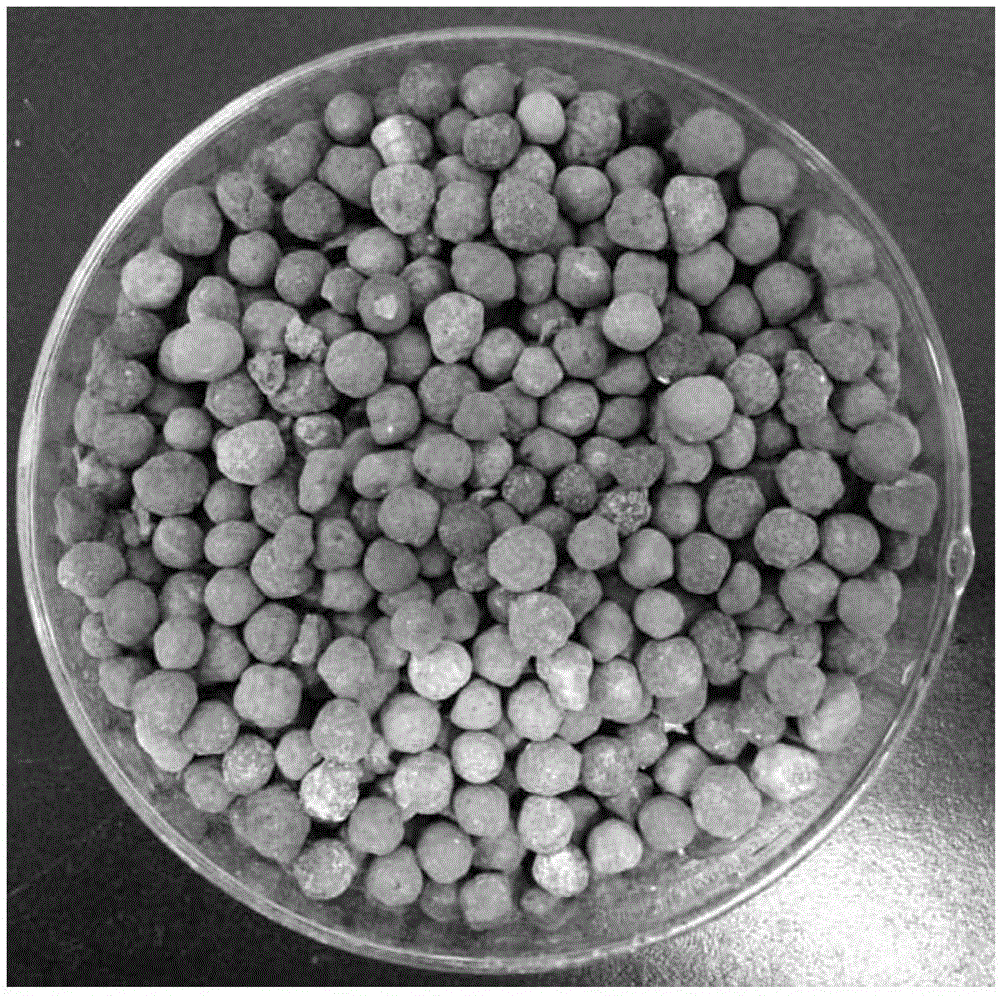

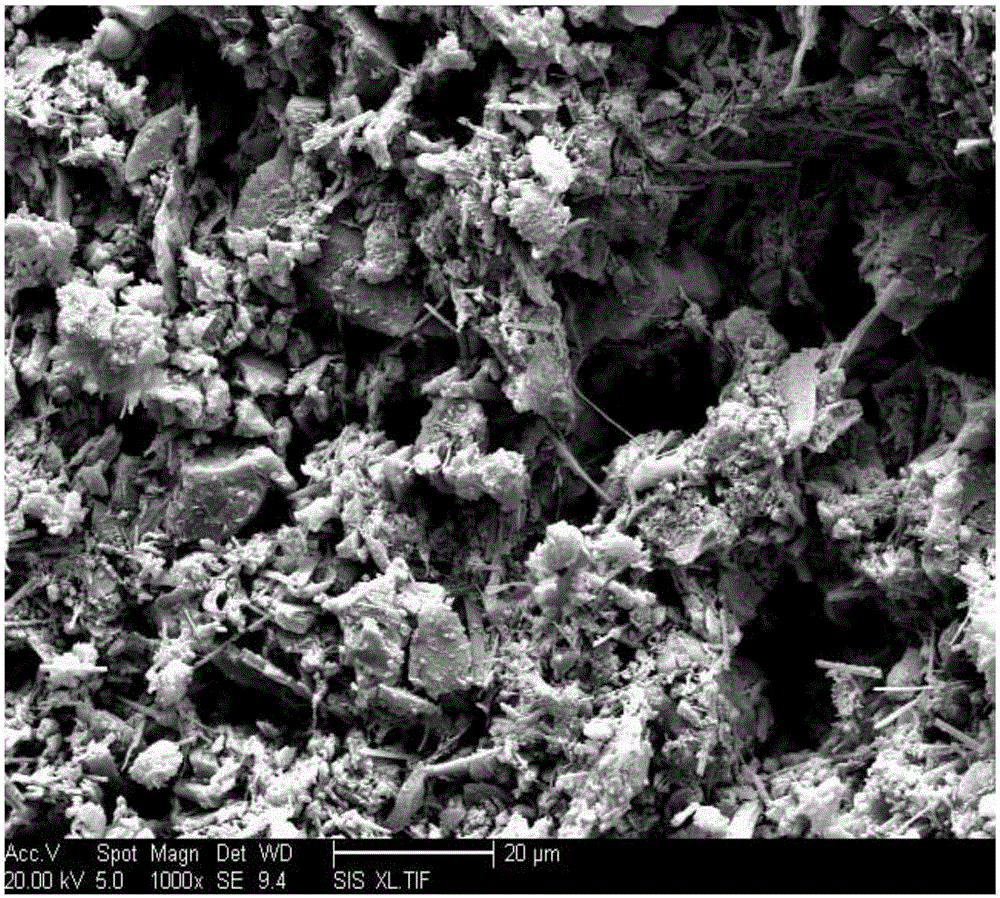

[0031] Specific embodiment one: a kind of new-type sintering-free fast film-forming biofiller of this embodiment consists of 18% to 37% sepiolite, 18% to 37% medical stone, 15% to 23% cement, 3% to 4.5% polyvinyl alcohol, 4.5% to 7% sodium alginate, 10% to 16% hydrogen peroxide with a volume concentration of 30%, 0.45% to 0.69% ferric chloride, 0.45 %~0.69% manganese sulfate, 0.63%~0.9% cobalt chloride and 1.5%~2.7% agar.

specific Embodiment approach 2

[0032]Specific embodiment two: the preparation method of a kind of new-type sintering-free fast film-hanging biological filler of the present embodiment is to carry out according to the following steps:

[0033] 1. Weigh 18% to 37% of sepiolite, 18% to 37% of medical stone, 15% to 23% of cement, 3% to 4.5% of polyvinyl alcohol, 4.5% to 7% sodium alginate, 10% to 16% volume concentration of 30% hydrogen peroxide, 0.45% to 0.69% ferric chloride, 0.45% to 0.69% manganese sulfate, 0.63% to 0.9% chloride Cobalt and 1.5% to 2.7% agar;

[0034] 2. Heat and dissolve the polyvinyl alcohol and sodium alginate weighed in step 1 in water, add after cooling the hydrogen peroxide with a mass concentration of 30% weighed in step 1 and mix evenly to obtain a liquid mixture;

[0035] 3. Grinding the sepiolite, medical stone, cement, ferric chloride, manganese sulfate, cobalt chloride and agar into powder and mixing uniformly to obtain a solid mixture;

[0036] 4. After mixing the liquid mixt...

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, take by weight 37% sepiolite, 18.52% medical stone, 18.56% cement, 3.70% polystyrene Vinyl alcohol, 5.56% sodium alginate, 12.96% volume concentration of 30% hydrogen peroxide, 0.56% ferric chloride, 0.56% manganese sulfate, 0.74% cobalt chloride and 1.84% agar. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com