Portland cement-sulphate aluminum cement-gypsum-polymer composite waterproof mortar and preparation method thereof

A technology of sulfoaluminate cement and Portland cement is applied in the field of preparation of waterproof mortar materials for construction projects, and can solve the problems of not well-solved performance problems, incomplete hydration reaction, poor waterproof effect, etc. Excellent construction performance, good hydrophobicity, high flexural and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

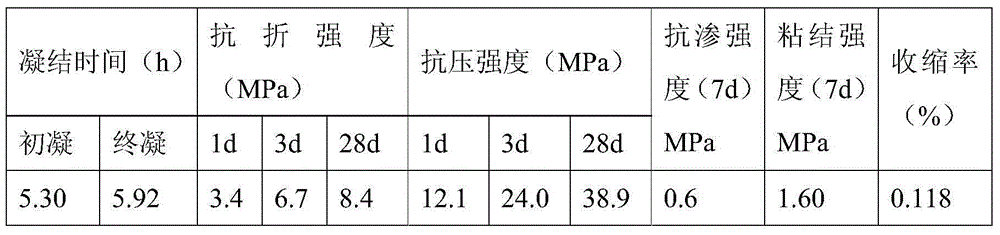

Embodiment 1

[0042] Inorganic cementitious materials: 50 parts of fly ash Portland cement, 13 parts of high-strength sulfoaluminate cement and 12 parts of dihydrate gypsum;

[0043] Redispersible latex powder: 7 parts of vinegar-propylene rubber powder; additive: 2.5 parts of sulfamate powder superplasticizer; filler: 15.5 parts of glass powder (2500 mesh); water-binder ratio: 0.6;

[0044] The preparation includes the following steps:

[0045] (1) Preparation of powder: In terms of mass parts, 50 parts of fly ash portland cement, 13 parts of high-strength sulfoaluminate cement, 12 parts of dihydrate gypsum, 7 parts of vinegar-propylene rubber powder, and 15.5 parts of glass powder Parts (2500 mesh) and 2.5 parts of sulfamate powder high-efficiency superplasticizer are accurately weighed, and then stirred with a dry powder mixer (rotation speed: 300r / min) for 30 minutes until the powder is fully mixed and evenly prepared to obtain the powder of waterproof slurry ;

[0046] (2) During con...

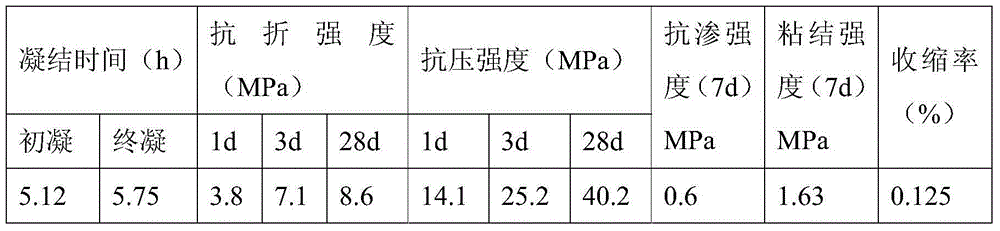

Embodiment 2

[0052] Inorganic cementitious materials: 49 parts of pozzolanic Portland cement, 21 parts of quick-hardening sulfoaluminate cement and 7 parts of anhydrous anhydrite; redispersible latex powder: 8 parts of EVA rubber powder; admixture: melamine type sulfonate 1.5 parts of high-efficiency powder superplasticizer of acidified polycondensate; filler: 13.5 parts of superfine calcium carbonate (1500 mesh);

[0053] Water-binder ratio: 0.5;

[0054] The preparation includes the following steps:

[0055] (1) Preparation of powder: in parts by mass, 49 parts of pozzolanic Portland cement, 21 parts of rapid hardening sulfoaluminate cement, 7 parts of anhydrous anhydrite, 8 parts of EVA rubber powder, superfine carbonic acid After accurately weighing 13.5 parts of calcium (1500 mesh) and 1.5 parts of melamine-type sulfonated polycondensate high-efficiency powder water reducer, stir with a dry powder mixer (rotating speed: 500r / min) for 15 minutes until the powder is fully mixed and eve...

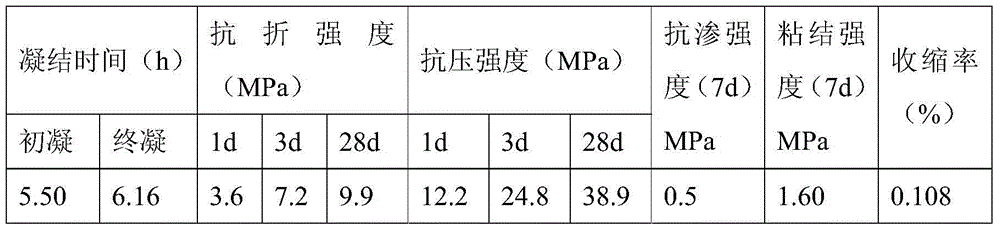

Embodiment 3

[0062] Inorganic cementitious materials: 48 parts of ordinary Portland cement, 12 parts of low-alkalinity sulfoaluminate cement and 6 parts of α hemihydrate gypsum;

[0063] Redispersible latex powder: 14 parts of SBR rubber powder; admixture: 3 parts of powder polycarboxylate superplasticizer; filler: 17 parts of superfine quartz sand (1000 mesh); water-binder ratio: 0.4;

[0064] The preparation includes the following steps:

[0065] (1) Preparation of powder: in parts by mass, 48 parts of ordinary Portland cement, 12 parts of low-alkalinity sulfoaluminate cement, 6 parts of α hemihydrate gypsum, 14 parts of SBR rubber powder, ultra-fine quartz After accurately weighing 17 parts of sand (1000 mesh) and 3 parts of powder polycarboxylate high-efficiency superplasticizer, stir with a dry powder mixer (rotation speed: 600r / min) for 14 minutes until the powder is fully mixed and evenly prepared to obtain a waterproof slurry Powder;

[0066] (2) During construction, pour the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com