Flexible high-dielectric polymer composite material and preparation method thereof

A composite material and ferroelectric polymer technology, which is applied in the field of electronic composite material preparation, can solve the problems of increasing the dielectric loss of composite materials, affecting the dielectric properties of materials, and limiting the properties of composite materials, so as to improve the dielectric constant and reduce the internal Defects, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

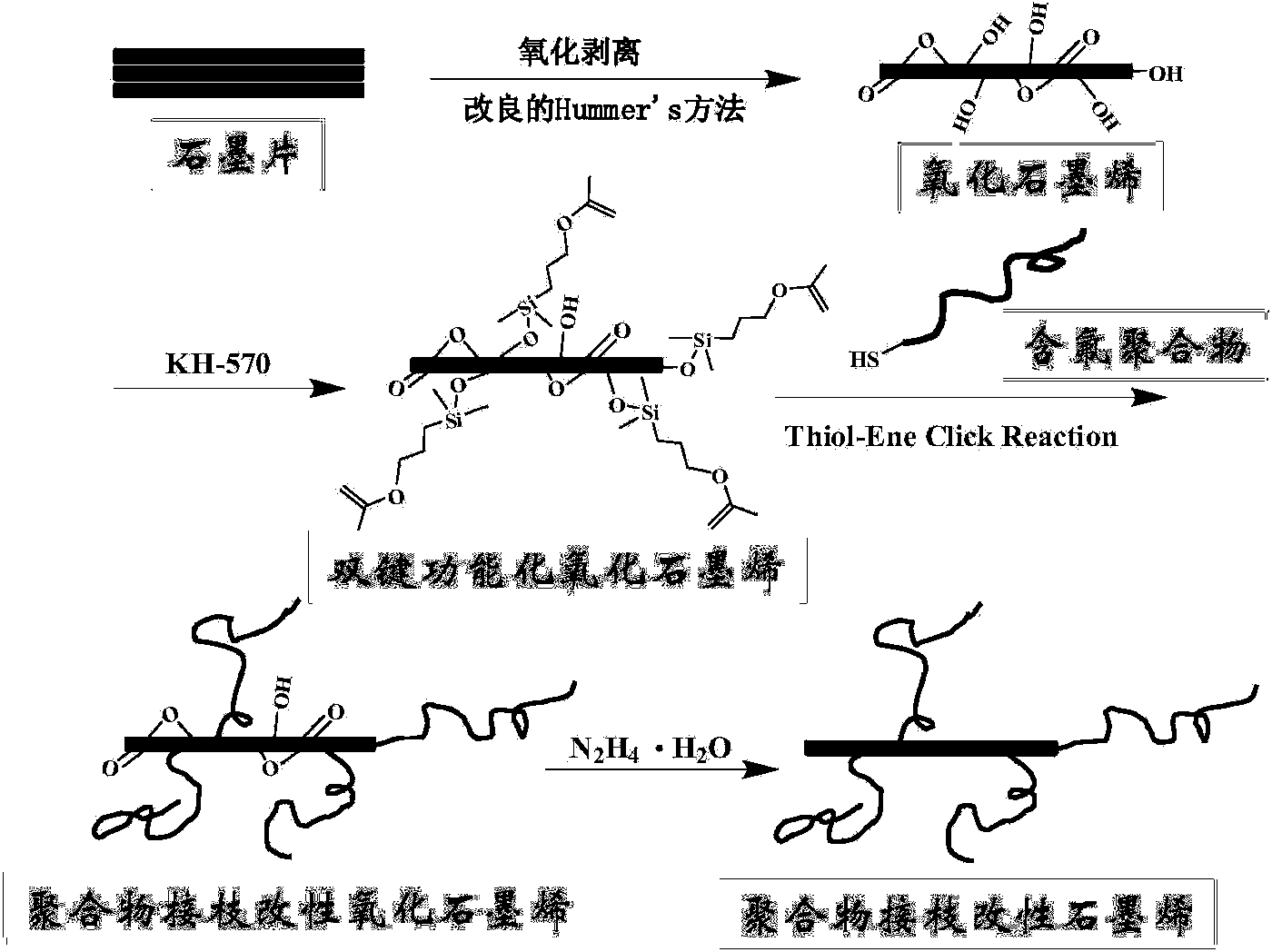

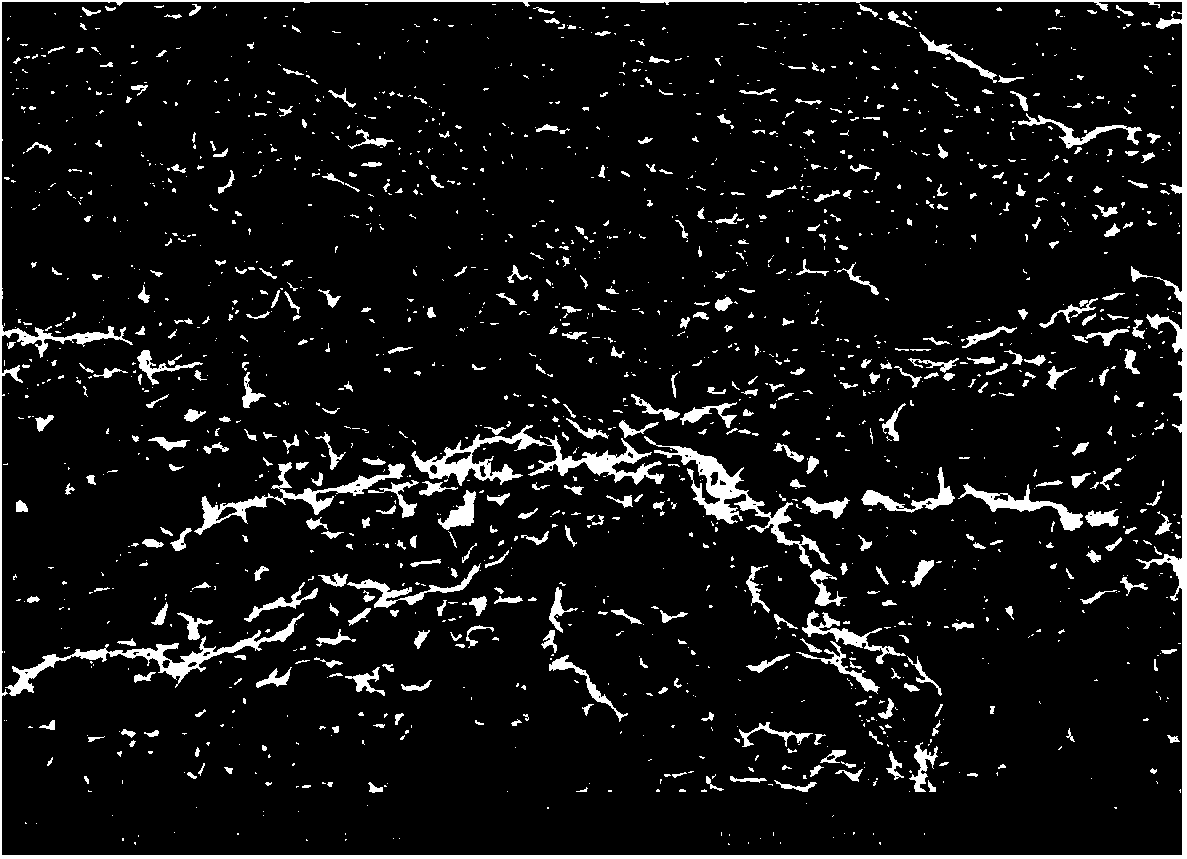

[0040] This embodiment relates to a kind of flexible high-dielectric composite material, and described composite material is the modified graphite grafted with polytrifluoroethyl acrylate by 98% mass fraction of P (VDF-HFP) as matrix and 2% mass fraction Alkenes are used as fillers. Wherein the modified graphene grafted with polytrifluoroethyl acrylate is prepared by the following steps:

[0041] A, chemical exfoliation of graphene: according to the improved Hummer's Method reported in the literature (G. Q.Shi, et al., J.Am.Chem.Soc., 2008, 130, 5856.), graphite oxide is prepared by chemical exfoliation alkene;

[0042] B, surface functionalization of graphene: ultrasonically disperse the graphene oxide in ethanol solution, and react with methacryloxypropyltrimethoxysilane (KH-570, Bailingwei Technology Co., Ltd.) to obtain grafted There is the functionalized graphene of the silane coupling agent of vinyl double bond; The consumption of described KH-570 can be 3~5% of graphe...

Embodiment 2

[0051] This embodiment relates to a kind of flexible high-dielectric composite material, and described composite material is by the PVDF of 99% mass fraction as substrate and the modified graphene grafted with polytrifluoroethyl methacrylate of 1% mass fraction as filler composition. The preparation of the graphene grafted and modified by polytrifluoroethyl methacrylate is the same as in Example 1, except that the grafted fluorine-containing polymer is trifluoroethyl methacrylate with terminal groups containing mercapto groups.

[0052] This embodiment also relates to a method for preparing a flexible high-dielectric polymer composite material, the method comprising the following steps:

[0053] Step 1, adding 4.95g of the fluorine-containing ferroelectric polymer matrix into 52mL N,N-diformamide solution, stirring and dissolving at 65°C to obtain A solution;

[0054] Step 2, adding 0.05 g of modified graphene grafted with polytrifluoroethyl acrylate to 13 mL of N,N-diformami...

Embodiment 3

[0058] This embodiment relates to a flexible high-dielectric composite material, the composite material is modified by 99.5% by mass fraction of P(VDF-TrFE) as a matrix and 0.5% by mass fraction of polyhexafluorobutyl methacrylate. Graphene is used as filler composition. The preparation steps of the graphene grafted and modified by polyhexafluorobutyl methacrylate are the same as those in Example 1, except that the grafted fluorine-containing polymer is polyhexafluorobutyl methacrylate with mercapto-containing terminal groups.

[0059] This embodiment also relates to a method for preparing a flexible high-dielectric polymer composite material, the method comprising the following steps:

[0060] Step 1, adding 4.975g of the fluorine-containing ferroelectric polymer matrix into 54mL N,N-diformamide solution, stirring and dissolving at 68°C to obtain A solution;

[0061] Step 2, adding 0.025 g of modified graphene grafted with polytrifluoroethyl acrylate to 12 mL of N, N-diforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com