Drinking water purification composite nano-filtration membrane and preparation process thereof

A composite nanofiltration membrane and preparation process technology, applied in the field of polyethersulfone and polyurethane blending new nanofiltration membrane and preparation technology, can solve the problem of inability to retain beneficial minerals, dead end filtration, and hollow ultrafiltration membranes that cannot withstand pressure and other problems to achieve the effect of excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

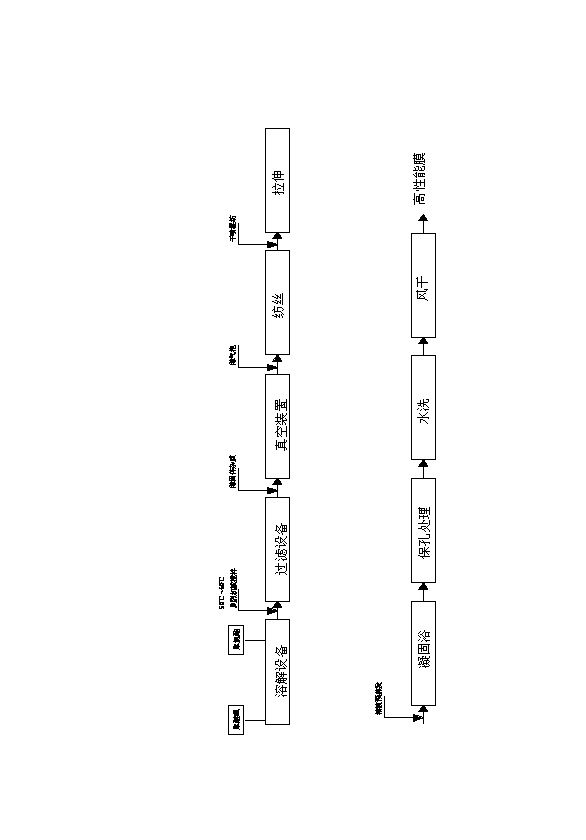

[0011] Preparation process of spinning dope:

[0012] Take polyethersulfone and polyurethane blending ratio according to 8:2, take dimethyl sulfoxide DMSO as solvent, and take 1% by weight of Mg(ClO 4 ) 2 The solids are used as additives. After the above substances are put into dissolution, they are filtered under a pressure of 0.2MPa to remove solid impurities, and the vacuum device is used to remove air bubbles to make a membrane casting liquid, and the vacuum degree is <-0.1MPa.

[0013] Normally, the temperature of the spinning casting solution is controlled at 40°C to 60°C, and the filtration pressure is at 0.2MPa to 0.4MPa.

[0014] Spinning and post-processing technology:

[0015] Spin the prepared casting solution by dry-jet wet spinning to form a composite nanofiltration membrane for drinking water purification. After stretching, the solvent in the nascent membrane is partially volatilized to complete the pre-evaporation of the solution, and then the nascent membran...

Embodiment 2

[0018] Embodiment two: technology and flow process are with embodiment one, and concrete process parameter is as follows:

[0019] Polyethersulfone: Polyurethane=8:2

[0020] Solvent: dimethyl sulfoxide DMSO

[0021] Additive (Mg(ClO 4 ) 2 ) amount: 20%

[0022] Spinning casting solution temperature: 50°C

[0023] Filtration pressure: 0.3MPa

[0024] Vacuum degree:﹤-0.1MPa

[0025] Spinneret: concentric circle plug-in type

[0026] Salivating temperature: 45°C

[0027] Salivation chamber humidity: 65%

[0028] Solvent pre-evaporation time: 30 seconds

[0029] Coagulation bath composition: dimethyl sulfoxide DMSO aqueous solution

[0030] Coagulation bath concentration: 40%

[0031] Coagulation bath temperature: 20°C

[0032] Stretch ratio: 1.8 times

[0033] Pore preserving agent: aqueous solution of ethylene glycol

[0034] Concentration: 30%

[0035]

Embodiment 3

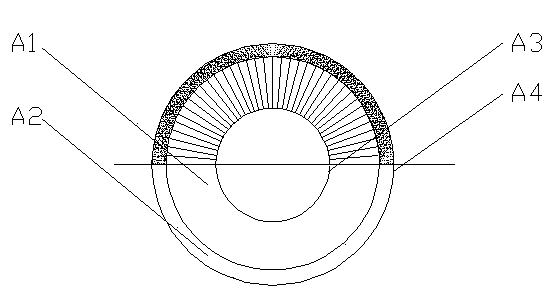

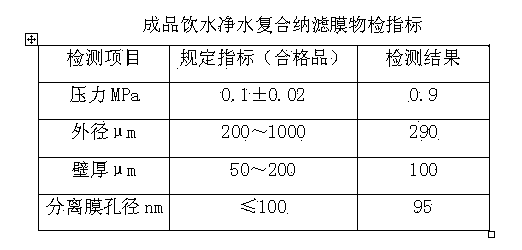

[0037] A composite nanofiltration membrane for drinking water purification is characterized in that its cross-sectional structure is that the inner wall of the high-performance composite membrane blended with polyethersulfone and polyurethane, the membrane support layer, the dense layer and the outer wall of the membrane are sequentially connected.

[0038] The invention has the advantages that: the drinking water purification compound nanofiltration energy membrane casting solution belongs to a partially compatible system, and there is microscopic phase separation in the system. The compatibility of the blending ratio solution is better, the film forming speed is suitable, the spinning process is continuous and stable, and the film performance is the best. The prepared composite nanofiltration energy membrane for drinking water purification has the characteristics of high temperature resistance, good acid resistance, alkali resistance, good hydrophobicity, oil resistance, toug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com