Preparation method of regular octahedron-type cobaltosic oxide

A technology of tricobalt tetroxide and regular octahedron, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of high energy consumption, volatile, safety hazards, etc., and achieve low energy consumption, smooth reaction, and small safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

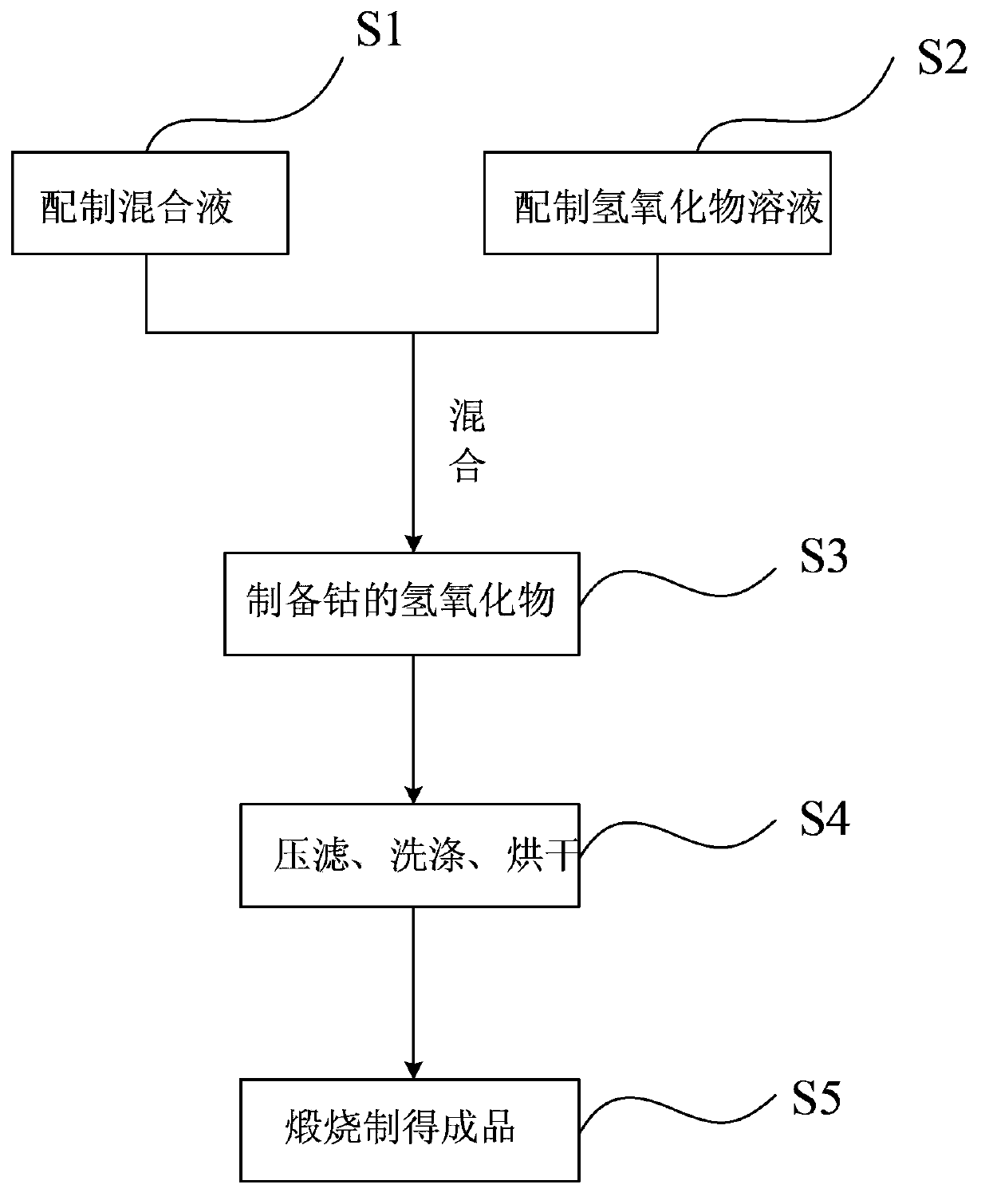

[0026] The preparation method of octahedral cobalt tetroxide provided by the present invention mainly solves the disadvantages that the current preparation cost of regular octahedral cobalt tetroxide is relatively high, and the safety hazards in the preparation process are relatively large. For this reason, the preparation method provided by the present invention includes the following steps:

[0027] S1) Prepare the mixed solution:

[0028] The cobalt salt is prepared into a uniform cobalt salt solution, and the concentration of cobalt ions in the cobalt salt solution is maintained within the range of 1.0-2.0mol / L, and then a complexing agent is added to the prepared cobalt salt solution to prepare a mixed solution to be prepared. use;

[0029] S2) Preparation of hydroxide solution:

[0030] The prepared hydroxide is prepared as a hydroxide solution for use, and the concentration of hydroxide in the hydroxide solution is preferably 5.0-10.0mol / L;

[0031] The solvent in ste...

Embodiment 1

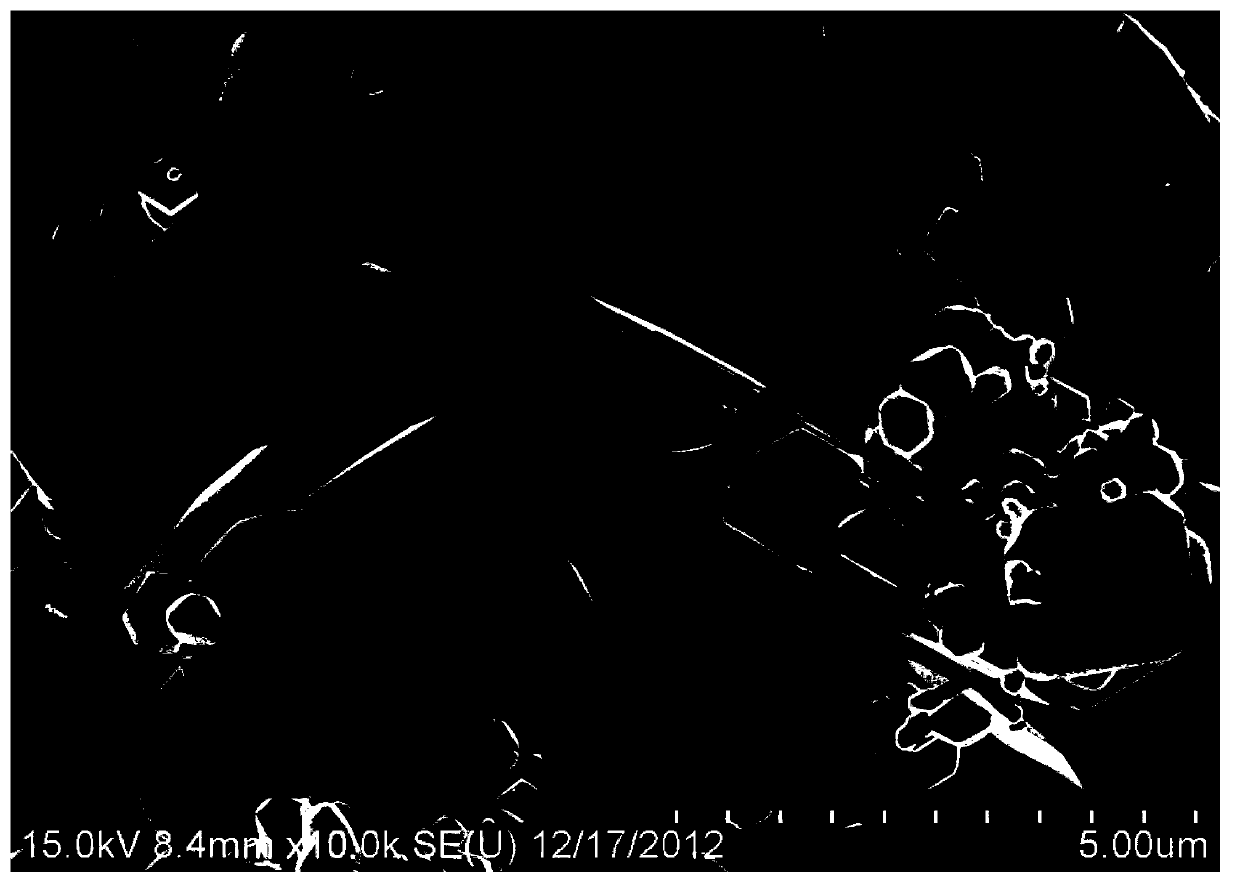

[0047] Cobalt chloride is formulated as a cobalt salt solution, and the molar concentration of cobalt ions in the solution is 1.5mol / L, and glycine is added as a complexing agent, and the molar concentration of glycine is 0.003mol / L (that is, 0.2% of the concentration of cobalt ions). %), at this time the preparation of the mixed solution is completed; the sodium hydroxide is prepared into a 9.0mol / L lye, and then the mixed solution and the lye are mixed and flowed into the reactor at a flow rate of 200L / h, and the The pH in the reaction kettle is controlled at 10.0, the reaction temperature is controlled at 65°C, and the stirring speed is controlled at 300rpm. After 8 hours of stirring reaction, the suspension is passed into an aging kettle with a temperature of 50°C for 3 hours of aging , and then press-filter the aged suspension to obtain cobaltous hydroxide, wash the cobaltous hydroxide three times with deionized water, and then enter the drying furnace to dry to obtain dry...

Embodiment 2

[0049] Cobalt sulfate is formulated as a cobalt salt solution with a cobalt ion molar concentration of 1.0mol / L, and histidine is added as a complexing agent, and the molar concentration of histidine is 0.005mol / L (that is, 0.5% of the cobalt ion concentration ), the preparation of the mixed solution is completed at this time; the potassium hydroxide is prepared into a lye with a concentration of 7.0mol / L, and the mixed solution and lye are passed into the reactor at a flow rate of 300L / h in parallel, and the reaction The pH in the kettle is controlled at 9.0, the reaction temperature is controlled at 45°C, and the stirring speed is controlled at 380rpm. After 16 hours of stirring reaction, the suspension in the reaction kettle is passed into an aging kettle at 70°C for 3 hours of aging. and then press-filter the aged suspension to obtain cobaltous hydroxide, wash the cobaltous hydroxide with deionized water for four times, and then dry it in a drying furnace to obtain dry coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com