Acid mine drainage OLWS method

A technology for acid mine wastewater and mine wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of low maintenance cost, strong processing ability and long effect time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

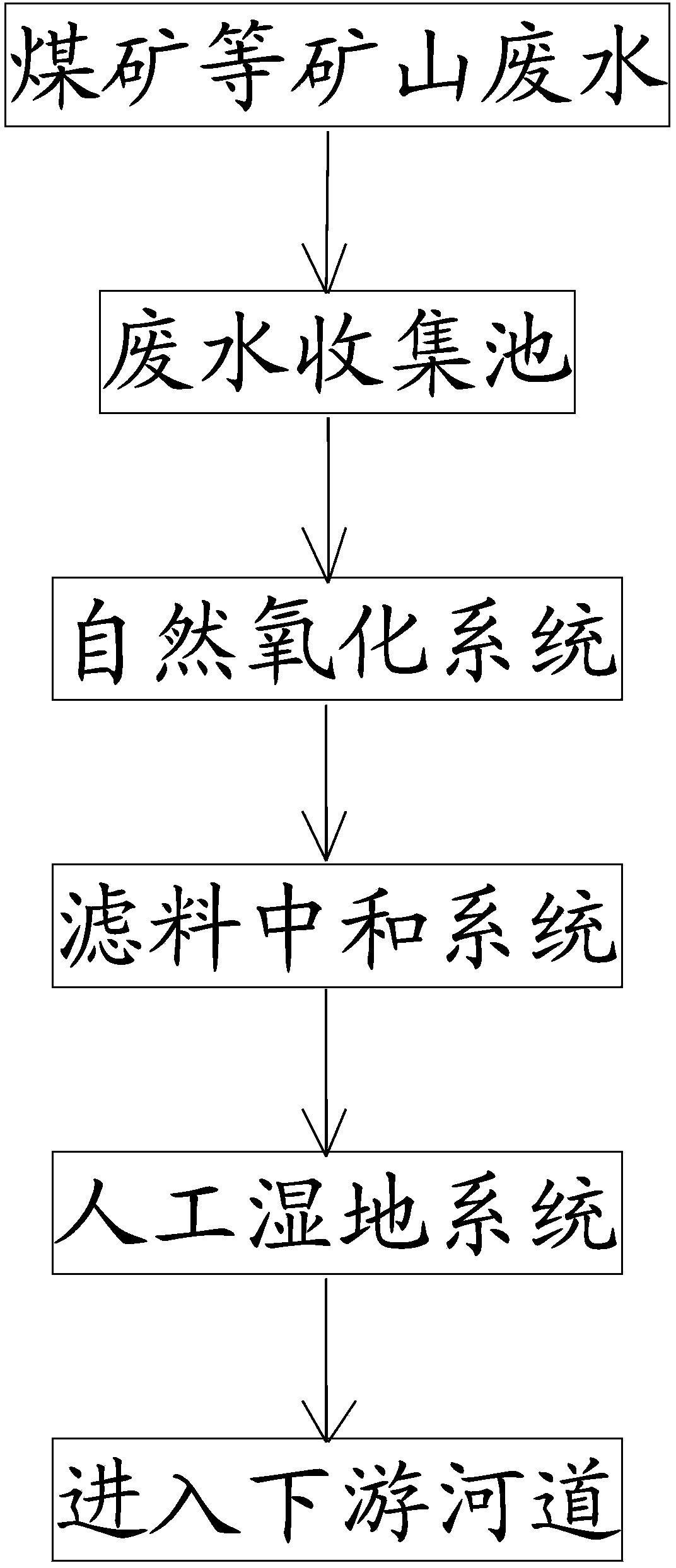

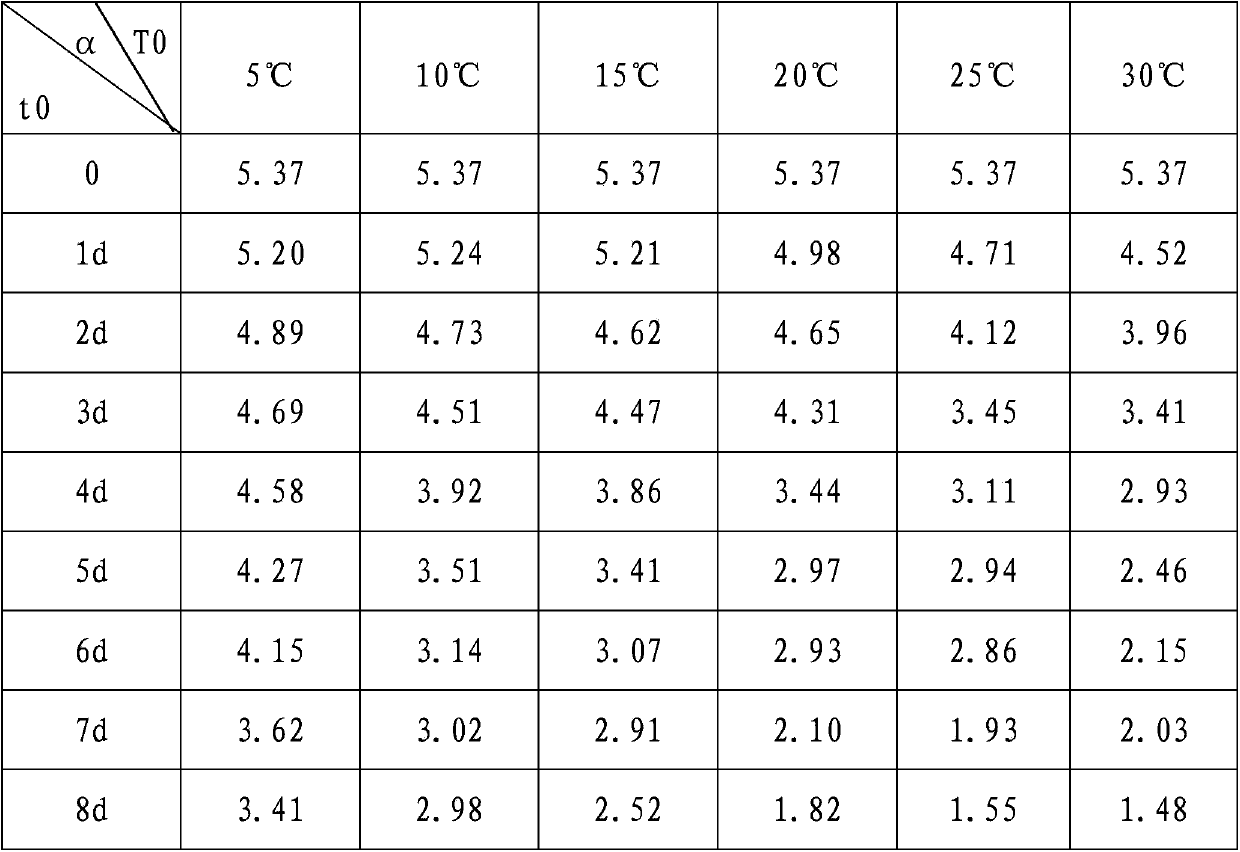

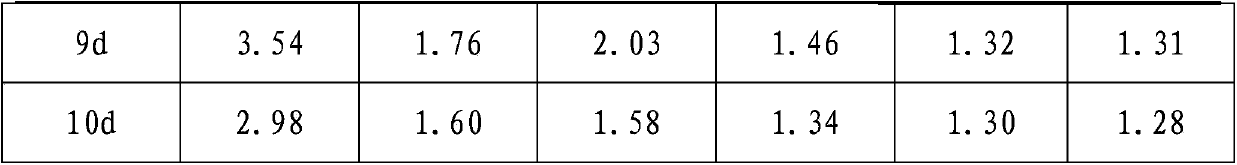

[0026] Embodiment 1: see figure 1 , firstly, the acid mine wastewater A is collected in the wastewater collection tank to ensure the stability of the subsequent process water; then, the acid mine wastewater A with a pH value of α=4.47 enters the natural In the oxidation system, a sulfuric acid-ferric sulfate solution is formed. At this time, the ambient temperature T0 of the natural oxidation system is T0=15°C, and the residence time of acidic mine wastewater in the natural oxidation system is t0=3d (days). The pH value of wastewater B is defined as β, where the β value needs to be determined according to the on-site detection, and the subsequent parameters are determined according to the detection value β; moreover, the acid mine wastewater B that has undergone the aforementioned treatment and has a pH value of β enters the filter containing calcium carbonate. The filter material neutralization system of the filter material increases the pH of the acid mine tailings water. Th...

Embodiment 2

[0027] Embodiment 2: First, the acid mine wastewater A is collected in the wastewater collection pond; then, the acid mine wastewater A with a pH value of α=5.37 enters the natural oxidation system in a quantitative manner (to prevent the impact of the excessive water volume on the treatment system, The oxidation system can adopt a number of water channels arranged at equal intervals, and the water inflow of each water channel also enters the acid mine wastewater A) in an equal flow manner to form a sulfuric acid / ferric sulfate solution. At this time, the ambient temperature of the natural oxidation system T0=25℃, acid The residence time of mine wastewater in the natural oxidation system is t0=0 hours (under the same temperature environment, the lower the pH value of acid mine wastewater A, the shorter the residence time in the oxidation system), the treated acid mine wastewater The pH value of B is defined as β, and β=4.92; moreover, the acid mine wastewater B with the pH valu...

Embodiment 3

[0028] Embodiment 3: This case is the acid mine wastewater treatment project in Shicheng Village, Yinkeng Township, Kaihua County. Using the acid mine wastewater OLWS method of the present invention, the values measured by the Changshan County Monitoring Station are as follows in Table 3:

[0029] The ambient temperature T0 and T1 here are 25°C, the residence time t0 of the acid mine wastewater in the natural oxidation system is about 48 hours, and the residence time t1 of the acid mine wastewater B in the filter material and the system is about 3 hours.

[0030] table 3

[0031]

[0032] The raw water here is acid mine wastewater A; the effluent of the oxidation system is acid mine wastewater B; the effluent of the neutralization system is acid mine wastewater C; the total drainage is treated discharge water.

[0033] If the wastewater collection tank is in the open air, the rainwater will have a greater impact on the wastewater collection tank. At this time, the wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com