Coating method of lithium manganite cathode material for lithium battery

A technology of using lithium manganate and cathode materials, applied in the field of new energy materials, can solve the problems of poor electrical conductivity of metal oxides and reduce the electrical conductivity of lithium manganate materials, so as to reduce structural defects, reduce direct contact, and reduce electrical losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

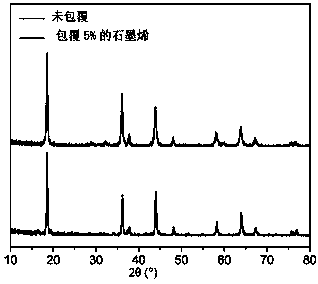

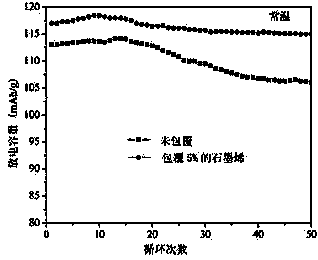

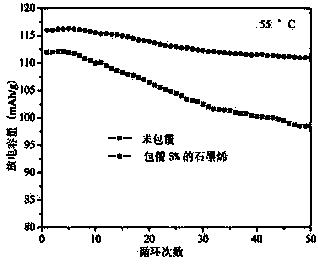

[0028] The present embodiment is spinel LiMn coated with 5% graphene 2 O 4 The coating method of the positive electrode material specifically includes the following steps:

[0029] (1) Prepare 100 ml of MnSO with a concentration of 2 mol / L 4 solution;

[0030] (2) Prepare 100 ml of sodium carbonate aqueous solution with a concentration of 2 mol / L, add ammonia water as a complexing agent, and the ammonia water concentration is 0.2 mol / L;

[0031] (3) Use a peristaltic pump to remove MnSO 4 The mixed aqueous solution of solution and sodium carbonate and ammoniacal liquor is continuously input in the reaction flask, and the flow rate is 5mL / min, and the water bath temperature of the reactor is 50 DEG C, and the slurry pH=8, and the stirring speed is 600 rmp;

[0032](4) after the reaction, the precipitation is centrifuged, washed with distilled water for many times to remove residual ions and dried at 80 °C to obtain a precursor;

[0033] (5) Combine the above precursor with...

Embodiment 2

[0038] This embodiment is spinel LiMn coated with 8% graphene 2 O 4 The coating method of the positive electrode material specifically includes the following steps:

[0039] Steps (1)-(5) are synchronized with Embodiment 1;

[0040] (6) get the above-mentioned lithium manganate 5g and disperse it in 200 ml of the ethanolic solution of graphite oxide with a concentration of 2 mg / mL, ultrasonically disperse for 0.5h, then centrifuge, and dry at 80 °C after centrifugation;

[0041] (7) Put the dried mixture of lithium manganate and graphite oxide into a vacuum tube furnace, and place it in a N 2 Fire at 600 °C for 1 h.

Embodiment 3

[0043] This embodiment is spinel LiMn coated with 5% graphene 2 O 4 The coating method of the positive electrode material specifically includes the following steps:

[0044] Steps (1)-(5) are synchronized with Embodiment 1;

[0045] (6) get the above-mentioned lithium manganate 5g and disperse it in 200 ml of graphite oxide aqueous solution with a concentration of 1.25 mg / mL, ultrasonically disperse for 1h, then centrifuge, and dry at 100 ° C after centrifugation;

[0046] (7) Put the dried mixture of lithium manganate and graphite oxide into the vacuum tube furnace, and put it in A 2 Atmosphere, 700 ° C under burning 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com