New method for producing fluoride and white carbon black by adopting fluosilicic acid or fluosilicate

A fluorosilicate and fluoride technology, applied in the field of co-production of white carbon black, can solve the problems of inability to recover fluorosilicate, low processing efficiency and high cost of raw materials, and achieve easy control of operating conditions, low reaction temperature, and low reaction temperature. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: with K 2 SiF 6 and KOH to prepare KF and SiO 2 .

[0029] 1. Add 6.6kg potassium fluorosilicate, 6.7kg KOH, 110kg water and 0.01kg SiO to the reactor 2 .

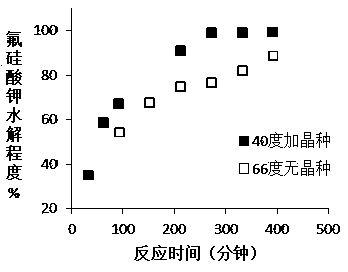

[0030] 2. Start stirring to make the reaction mixture react under stirring to generate potassium fluoride and SiO 2 .

[0031] 3. Turn on the constant temperature control device and set the temperature inside the reactor to a constant temperature of 40 °C.

[0032] 4. Measure the fluoride ion content of the solution in the reaction kettle, and turn off the stirring device when the reaction end point is reached.

[0033] 5. Centrifuge the solution and precipitate in the reactor, the solution is potassium fluoride, and the precipitate is SiO 2 .

[0034] 6. Concentrate the crystalline potassium fluoride solution to obtain KF.

[0035] 7. SiO 2 After washing, it is placed in a drying box and dried to obtain white carbon black.

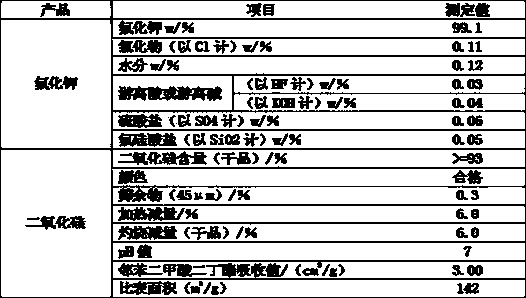

[0036] The potassium fluoride and silicon dioxide products prepared...

Embodiment 2

[0039] Embodiment 2: Treat fluorine-containing waste water with KOH, prepare KF and SiO 2 .

[0040] 1. It has been determined that the fluorine-containing wastewater contains 7.7kg hydrogen fluoride and 9.6kg fluosilicic acid per 100kg.

[0041] 2. Add 100kg of fluorine-containing wastewater, 44kg of KOH and 0.02kg of SiO to the reactor 2 .

[0042] 3. Start stirring to make the reaction mixture react under stirring to generate potassium fluoride and SiO 2 .

[0043] 4. Turn on the thermostatic control device to control the temperature in the reactor to 40 °C.

[0044] 5. Measure the fluoride ion content of the solution in the reaction kettle, and turn off the stirring device when the reaction end point is reached.

[0045] 6. Centrifuge the solution and precipitate in the reactor, the solution is potassium fluoride solution, and the precipitate is SiO 2 .

[0046] 7. Concentrate the crystalline potassium fluoride solution to obtain KF.

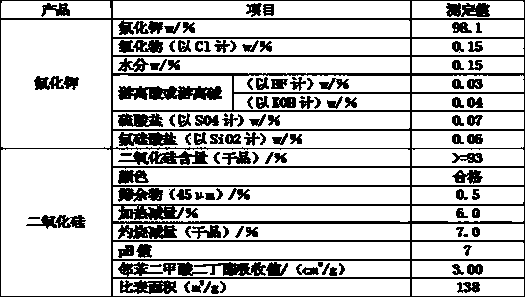

[0047] 8. SiO 2 After washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com