Modified hyperbranched polyamide-amine asphalt emulsifier and preparation method and application thereof

A technology of hyperbranched polyamide and asphalt emulsifier, applied in building components, building insulation materials, buildings, etc., can solve the problems of complex polyethylene polyamine structure, high raw material cost, harsh reaction conditions, etc., to improve construction speed and The effect of reliability, excellent workability, and sufficient mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

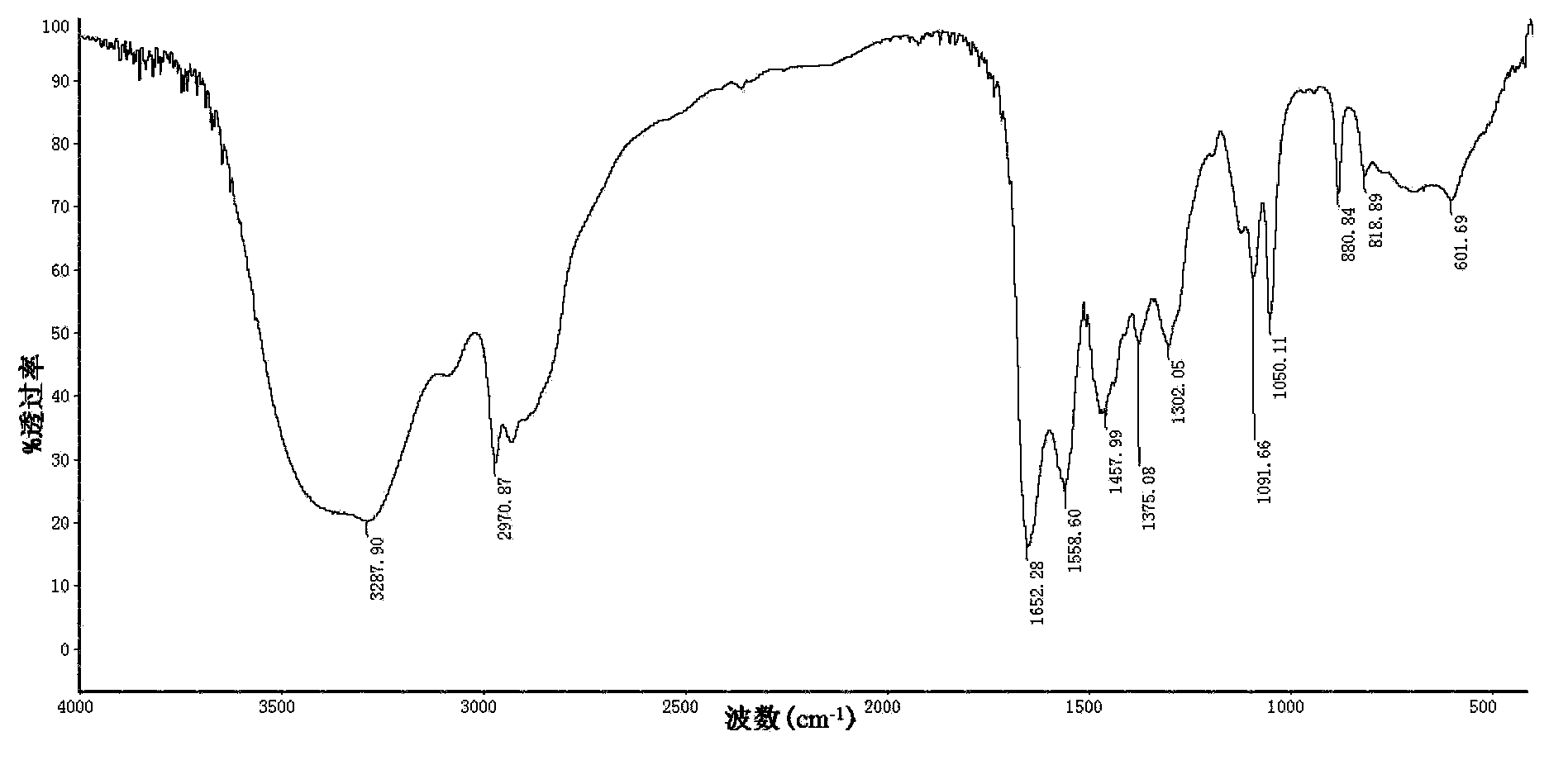

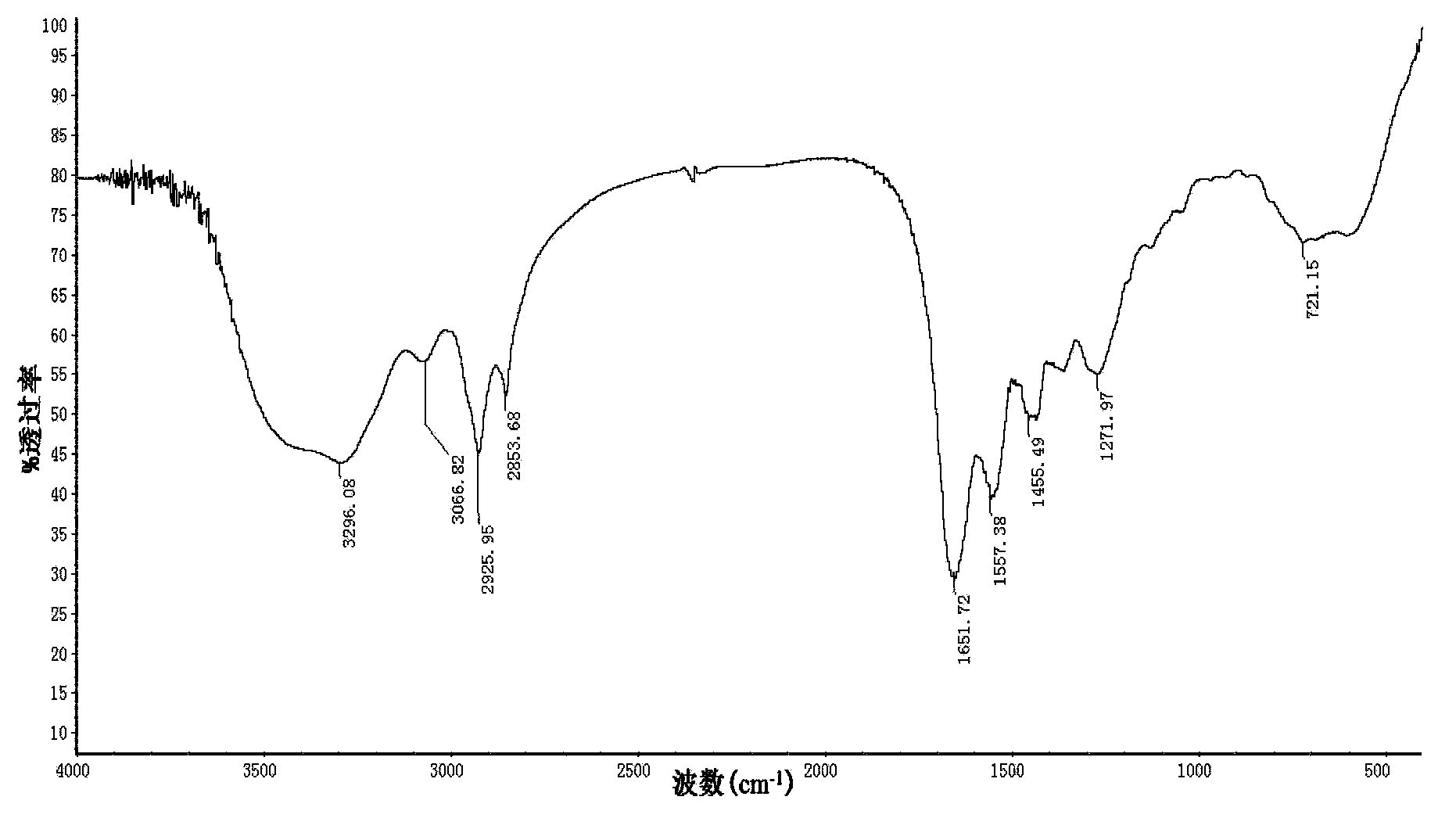

[0036] (1) Synthesis of hyperbranched polyamidoamines

[0037] Put 20.8g (0.2mol) of diethylenetriamine in a 250ml three-necked flask, and cool it in an ice-water bath; 2 Under the protection of the atmosphere, use a constant pressure dropping funnel to slowly drop a mixed solution of 17.6g (0.2mol) methyl acrylate and 40ml methanol; after the drop is completed, react at room temperature for 8 hours to obtain a colorless and transparent AB 2 type monomer. Then, the reaction product AB 2 The monomer was transferred to an eggplant-shaped flask of a rotary evaporator, the methanol was distilled off under reduced pressure, the temperature was raised to 140°C, the reaction under reduced pressure was continued for 3 hours, and the reaction was stopped to obtain a viscous light yellow liquid. Precipitated by acetone, filtered, separated, and then vacuum-dried at 40°C for 48 hours to obtain a yellow viscous product. Concrete reaction process is as follows:

[0038]

[0039] The...

Embodiment 2-3 and comparative Embodiment 3-5

[0083] Using diethylenetriamine (DETA) and methyl acrylate (MA) as raw materials, a Michael addition reaction occurs to obtain AB 2 type monomer. Investigate the impact of raw material feed ratio on the final product, under the conditions of reaction temperature of 40°C and reaction time of 8h, change the feed ratio, the feed amount of embodiment 2-3 and comparative example 3-5, test the final polymer Viscosity, primary amine value, total amine value, as shown in the following table:

[0084]

[0085] From the test results in the above table, it can be seen that when the feeding ratio of diethylenetriamine and methyl acrylate is 1:1.2, the viscosity of the system is relatively high, which can correspondingly indicate that there are more monomers undergoing polycondensation reaction and the molecular weight is larger; the feeding ratio is 1 :1, the product viscosity and amine value are slightly smaller; and when the feed ratio is 1:2 and 1:1.5, the system gels; when the fee...

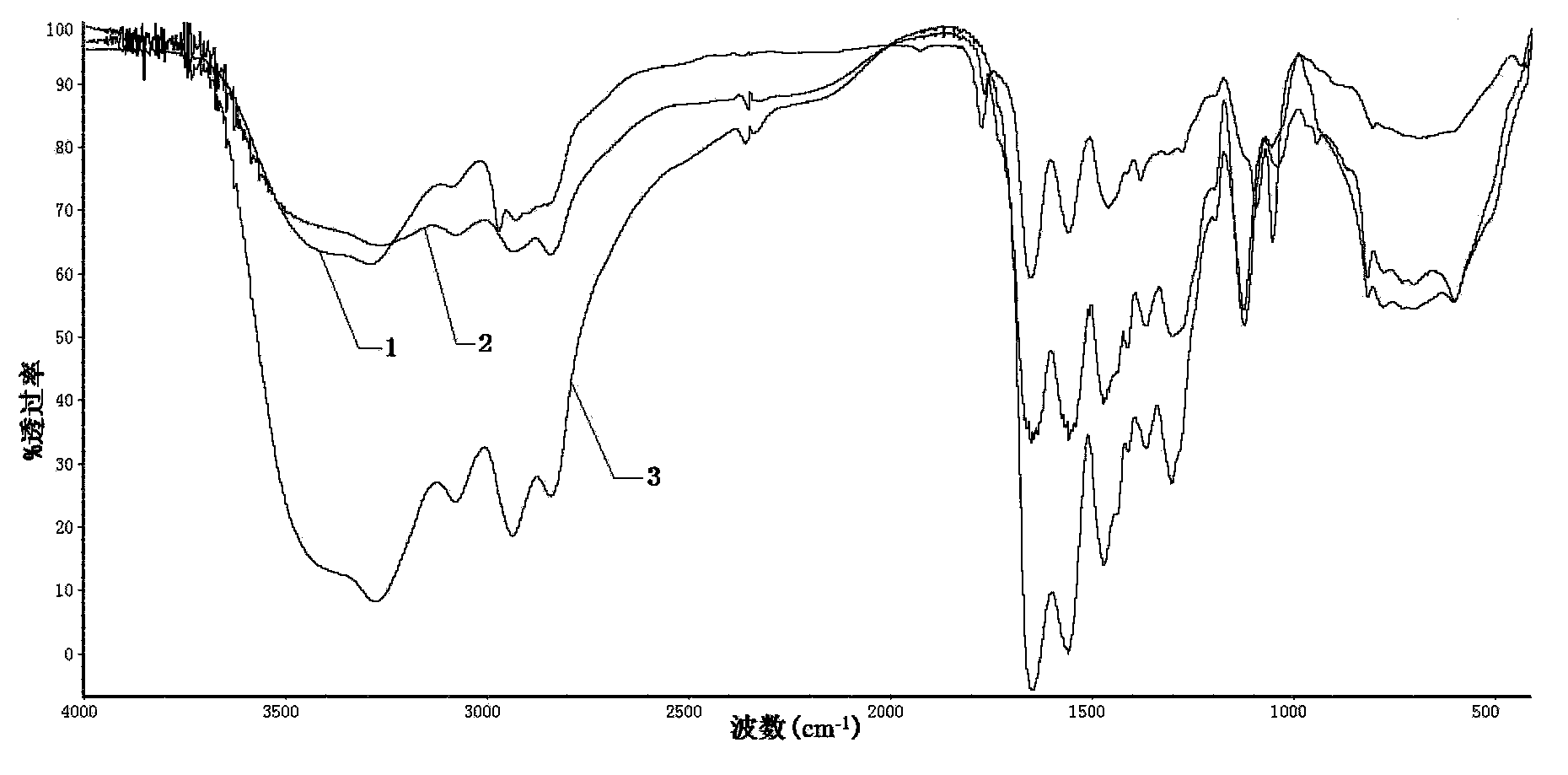

Embodiment 4

[0088] Get AB in embodiment 1 2 10g of the type monomer is placed in an eggplant-shaped bottle, the temperature is raised to cause its own melting polycondensation reaction, and the change process of the infrared spectrum of the reaction system is tested. image 3 It is the infrared spectrogram of the product after the melt polycondensation reaction for 1 hour under different temperature conditions, where line 1 is the polymerization reaction at 80°C, line 2 is the polymerization reaction at 120°C, and line 3 is at 140°C Polymerization. It can be seen from the figure that there is already a certain amount of amide bonds at 80°C (amide I 1645cm -1 , amide II 1559cm -1 ) appear, and with time and temperature changes, the ester bond (at 1720cm -1 left and right) gradually decrease, and the amide bond gradually strengthens. Moreover, after one hour at 140°C, the ester bond has basically disappeared, and in the subsequent reaction, there is basically no change in the infrared, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com