A kind of eva hot melt adhesive material and preparation method thereof

A hot-melt adhesive and material technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of poor mechanical strength of EVA hot-melt adhesives that cannot meet the requirements of difficult-to-bond materials and corresponding fields. Not resistant to high and low temperature, etc., to achieve significant social and economic benefits, high bonding strength, and prevent glue seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of described EVA hot-melt adhesive material comprises the following steps:

[0040] (1) In the pre-dried part of EVA and maleic anhydride, add an initiator to prepare EVA-MA;

[0041] (2) Heat and melt the remaining EVA, EVA-MA, LLDPE, waxes, plasticizers, antioxidants and other additives;

[0042] (3) After the material in step (2) is completely melted, add whitening agent and stir vigorously;

[0043](4) When the temperature of the blended material in step (3) reaches 100-150°C, add a tackifier and continue stirring in a molten state to obtain a uniform viscous liquid substance;

[0044] (5) After cooling the material obtained in step (4) for 1-24 hours, the EVA hot-melt adhesive material is obtained.

[0045] Steps (2)-(4) are carried out under an inert atmosphere, and the inert gas is one or more of nitrogen, helium, neon, argon, and krypton.

Embodiment 1

[0048] This example illustrates the hot melt adhesive composition, hot melt adhesive and their preparation methods provided by the present invention.

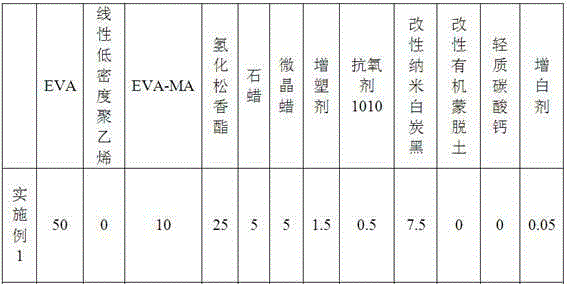

[0049] According to the following formula: by weight (g)

[0050] First, preheat EVA, MA and LLDPE in an oven at 80-100°C to remove the moisture contained therein. Then weigh 50g of EVA and 10g of MA and put them in the reactor, then add 0.1~0.3g of initiator dicumyl peroxide (DCP), and react at 100~130°C for 1~3h to obtain the compatibilizer ethylene-vinyl acetate copolymer substance / maleic anhydride (EVA-MA);

[0051] Then add EVA, EVA-MA, modified nano-silica, paraffin wax, microcrystalline wax, dioctyl phthalate, antioxidant 1010, etc. into the reactor in sequence according to the quality shown in the table, and heat and melt; When the material is completely melted, add the brightener sodium distyrene biphenyl disulfonate and stir vigorously; when the temperature of the blended material reaches 100~150°C, add hydrogenated...

Embodiment 2~6

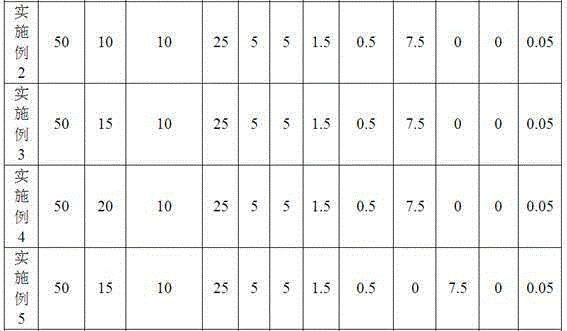

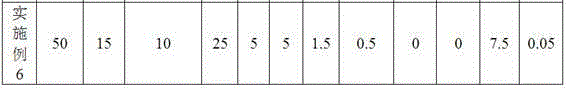

[0054] Each raw material was weighed according to the composition of raw materials in the following table, and the processing steps and process parameters were the same as in Example 1 to obtain a maleic anhydride graft-modified EVA hot-melt adhesive.

[0055]

[0056]

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com