A kind of method that utilizes lead-zinc tailings to prepare inorganic mineral polymer

A technology of inorganic minerals and polymers, applied in the direction of cement production, etc., can solve problems such as difficult to use, tailings pollution, etc., and achieve the effects of improving activation degree, short calcination time and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

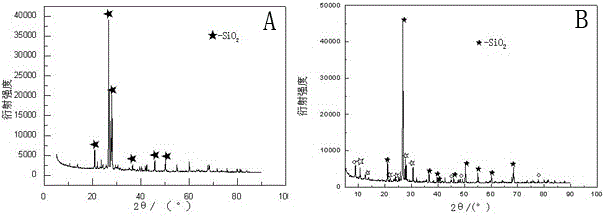

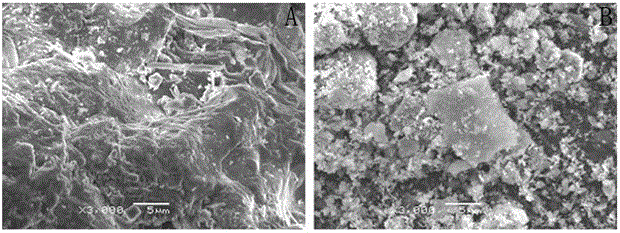

Image

Examples

Embodiment 1

[0030] The lead-zinc tailings that the embodiment of the present invention adopts comes from Fujian Jindong mining industry, and main component is SiO 2 38.49%, Fe 2 o 3 19.86%, CaO14.51%, SO 3 12.62, Al 2 o 3 5.14%, MnO4.10%, MgO3.41%;

[0031] The metakaolin used in the embodiments of the present invention has a whiteness value of 90-95%, a loss on ignition <0.25%, a pH value of 6-7, a water content of ≤0.3%, and a residue of 325 mesh <0.4%;

[0032] The modulus of the sodium silicate solution that the embodiment of the present invention adopts is 2.8, Na 2 O content is 11.6%, SiO 2 The content is 39.8%;

[0033] The NaOH used in the embodiments of the present invention is an analytically pure reagent, a white flaky solid with a solid content of not less than 96%;

[0034] The main equipment used in the embodiment of the present invention is a high-temperature resistance furnace, an electric blast drying oven, an electronic hydraulic pressure testing machine, an elec...

Embodiment 2

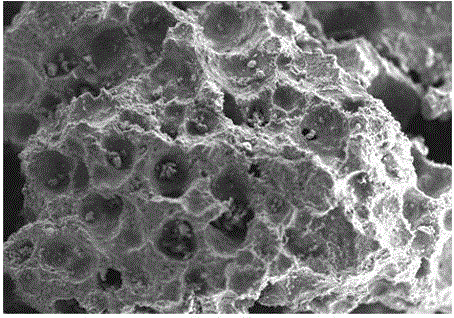

[0045] The inorganic mineral polymer prepared in Example 1 is mixed with 2.25g sodium lauryl sulfate and 1g stearic acid, poured into the test mold immediately, the mixture expands immediately, and the expansion ends within 10 minutes, followed by exotherm after 25 minutes The reaction starts to harden, and it is formed after 60 minutes. After 24 hours, it is demoulded, and then put into a curing box for curing. After 28 days, it is taken out to obtain a foamed inorganic mineral polymer test piece.

[0046] After testing, the strength of the foamed inorganic mineral polymer test block in this embodiment can reach up to 3.5MPa, and the thermal conductivity can reach 0.056w / m·k. The foamed inorganic mineral polymer test piece of this example was dried at 100°C for 1 hour, and the test piece was intact; then the test piece was calcined at 500°C and 1000°C for 2 hours, although a little Cracking, volume shrinkage and mass change rate are larger than those at 500°C, but there is no...

Embodiment 3

[0048] The inorganic mineral polymer prepared in Example 1 is mixed with 22.5g of hydrogen peroxide, 2g of polyvinyl alcohol and 6g of deionized water and then poured into the test mold. After expansion molding, the mold is demoulded in 24 hours, and then put into the curing box for curing. After 28 days Take out and obtain the foamed inorganic mineral polymer test block.

[0049] The foaming principle of hydrogen peroxide is as follows:

[0050] 2H 2 o 2 ﹦2H 2 O+O 2 ↑;

[0051] Polyvinyl alcohol can act as a surfactant in the system, which can make the gas produced by hydrogen peroxide better contact the slurry and maintain a good pore structure; the water flux of the porous material prepared without deionized water is 0, judging that hydrogen peroxide can only form independent closed pores, and adding deionized water can create small interconnected pores connecting these closed pores, and the size of the pores can be adjusted by adjusting the amount of deionized water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com