A method for advanced treatment and desalination reuse of high-salt industrial wastewater

A technology for advanced treatment of industrial wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as large concentrated water discharge, serious membrane pollution, and huge equipment , to achieve good removal effect and high catalytic oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Direct electrodialysis desalination of coal chemical industry saline wastewater

[0040] Coal chemical industry saline wastewater, although COD and ammonia nitrogen have reached the effluent standard, due to the presence of Cl - Inorganic salts such as ions, a small amount of refractory organic matter, suspended particles and bacteria limit its recycling, and further removal of Cl is required. - Inorganic ions and other pollutants. Electrodialysis technology is used for desalination treatment, and constant potential operation is adopted. Concentrated water and fresh water are filtered by 5μm filter elements and then desalted by electrodialysis.

[0041] After 10 batches of continuous desalination experiments, it was found that the Cl in the fresh water of the initial batch of desalination experiments - Ions can quickly drop below 250mg / L to meet the reuse standard. However, in each batch of experiments, the current density showed a downward trend with the p...

Embodiment 2

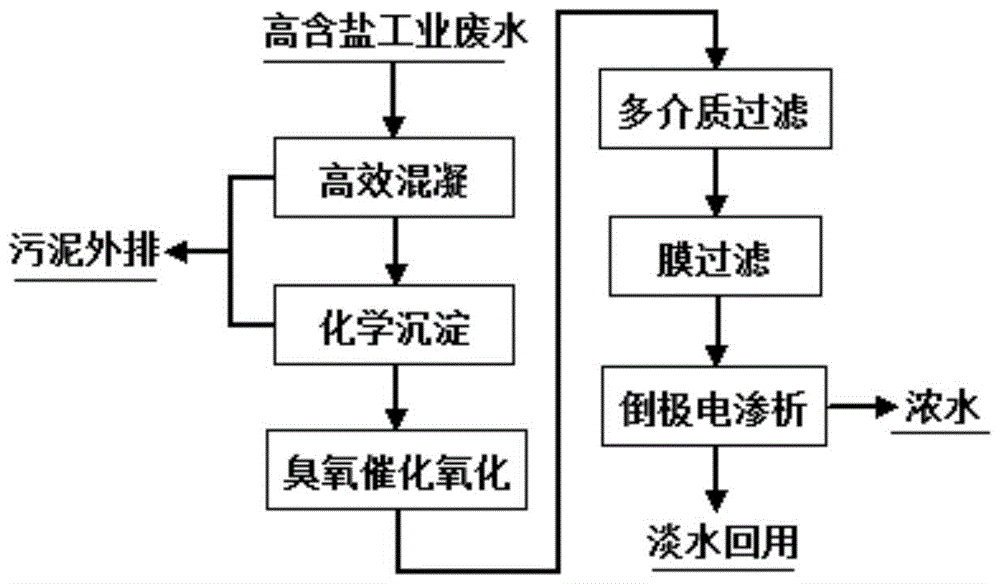

[0042] Example 2 Advanced treatment and desalination reuse of coal chemical industry salty wastewater

[0043] According to the water quality characteristics of coal chemical industry salty wastewater, high-efficiency coagulation-chemical precipitation-ozone catalytic oxidation-multimedia filtration-precision filtration-membrane filtration, etc. are used to pre-remove bacteria, suspended particles, Colloids, macromolecular organics, Ca 2+ and Mg 2+ and other high-priced ions, etc., and then use inverted electrodialysis to remove soluble inorganic salts in wastewater. Among them, when high-efficiency coagulant is used to treat high-salt industrial wastewater, the removal rate of organic matter in wastewater can reach 30-50%, and cyanide can reach more than 90%; then add NaOH and soda ash for chemical precipitation to remove Ca in wastewater 2+ and Mg 2+ and high-valent ions, etc., to reduce the concentration of these ions to below 50mg / L; use carbon-based composite high-effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com