A kind of supercapacitor based on graphene material and manufacturing method thereof

A technology for supercapacitors and manufacturing methods, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor separators, hybrid capacitor electrodes, etc., can solve the problems of no finished products, and achieve low space occupation, large capacity, and operating temperature range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

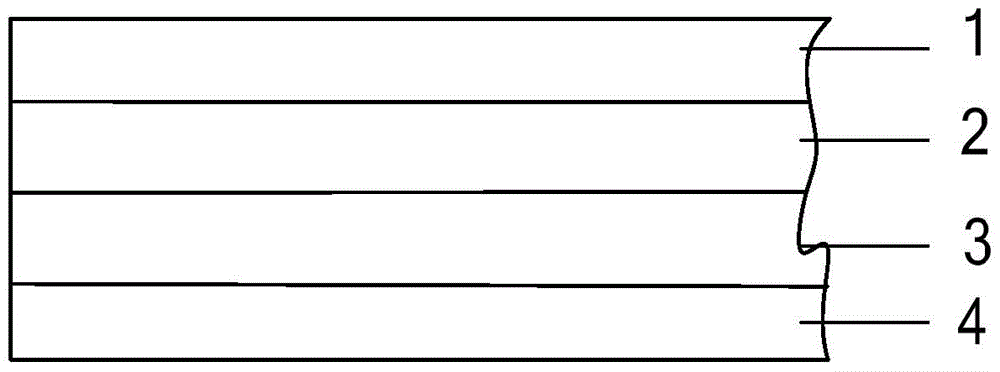

[0054] Embodiment 1 Supercapacitor structure of four-layer structure ultra-thin flexible composite strip plate

[0055] figure 1 A supercapacitor structure with four-layer ultra-thin flexible composite strip plates is given, in which 1 is the first plate, 2 is the dielectric film; 3 is the second plate; 4 is the insulating film.

[0056] The first pole plate 1 and the second pole plate 3 are ultra-thin graphene pole plates formed by adsorbing graphene material on the three-dimensional mesh-shaped nickel foam; the dielectric film 2 is a glass fiber reinforced polypropylene material The insulating film 4 is a film layer of ultra-high pressure polyethylene material coated on the outer surface of the first pole plate 1 or / and the second pole plate 3 . That is, the insulating film 4 can be plated on the outside of any one of the first pole plate 1 and the second pole plate 3 , or the insulating film 4 can be plated on the outside of the first pole plate 1 and the second pole plate...

Embodiment 2

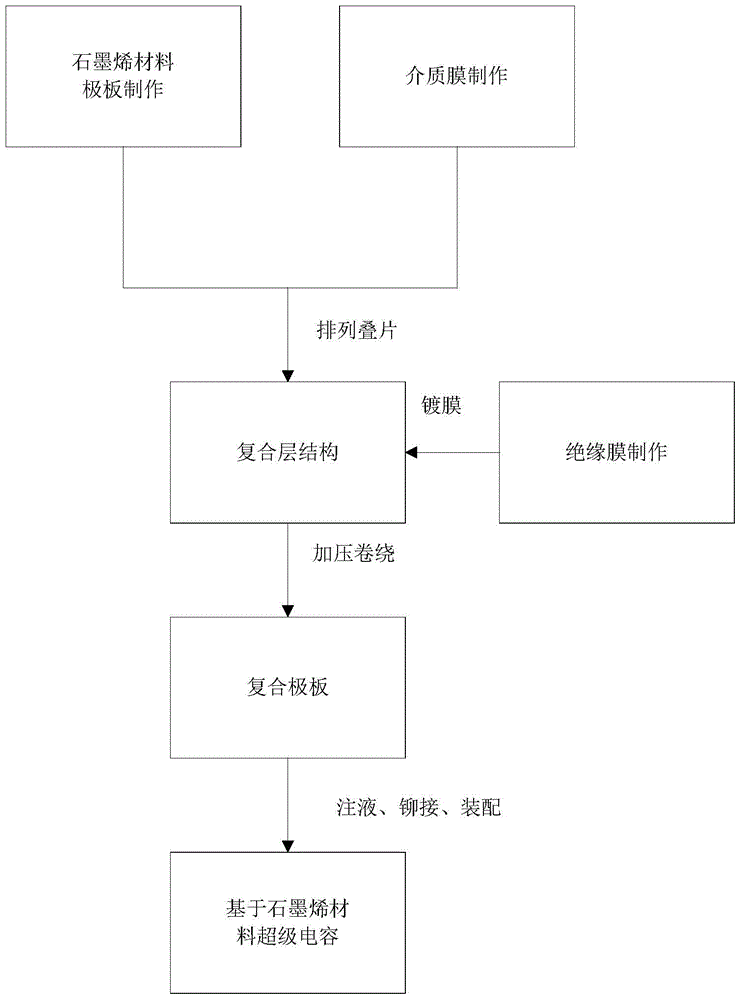

[0059] Embodiment 2 Principles of the present invention and overall process flow

[0060] The invention aims at producing a new type of battery to replace traditional fuel and chemical batteries and apply it to corresponding electrical appliances. First of all, we must consider two points: one is whether the manufactured supercapacitor can guarantee the demand of energy supply; the other is whether the volume of the ultra-capacity battery obtained by the present invention can meet the miniaturization standard. By choosing graphene material as the supercapacitor plate material, we invented a mesh-locked film ultra-thin graphene plate to greatly improve the energy storage performance of the supercapacitor; by introducing high pressure resistance, high strength, The enhanced polymer material with high toughness and ultra-thin characteristics is used as the supercapacitor dielectric film and insulating film material, and the ultra-thin composite flexible strip plate is designed to...

Embodiment 3

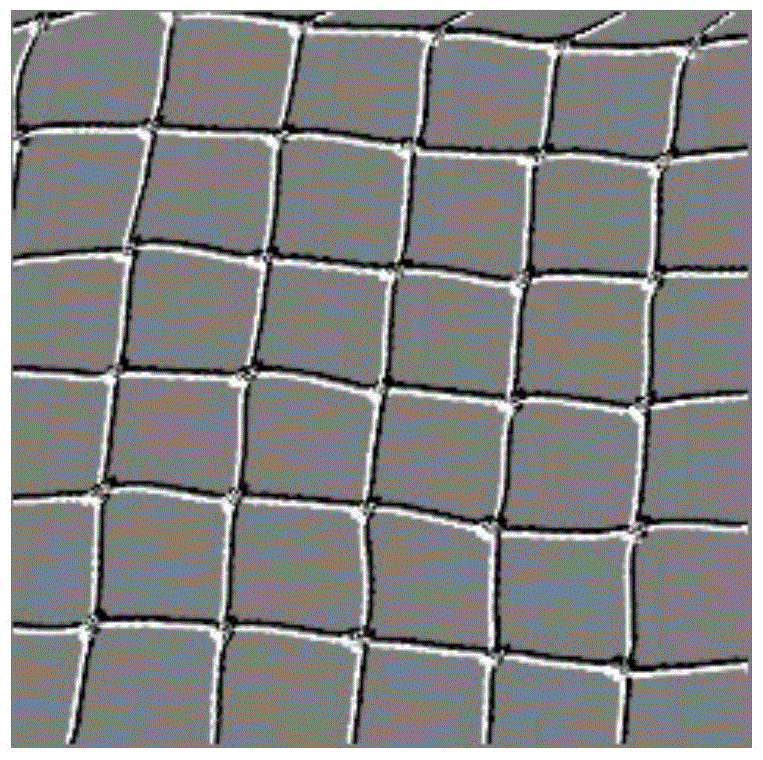

[0069] Example 3 Fabrication of ultra-thin graphene pole plate with mesh-locked film

[0070] The present invention utilizes the novel material graphene to make supercapacitors. The preparation of the polar plate is to prepare graphene by chemical method, mix it with polytetrafluoroethylene emulsion with a mass concentration of 10%, and stir it uniformly for 3 hours to make a slurry; add water to the slurry and stir to obtain a mixed solution, add water The amount should be such that every 500ml of the mixed solution contains 10-40g of graphene. After stirring, immerse the reticular nickel foam into the mixed solution. Using the super adsorption of the graphene material, the graphene material is adsorbed on the mesh by ultrasonic assistance. On the foamed nickel current collector, an ultra-thin graphene film with a mesh-locked film is formed; the film is dried under vacuum for 2 hours, and the thickness is reduced to 1 μm to 1000 μm at a high pressure of 20 MPa, and an ultra-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com