Electrolyte as well as preparation method thereof and lithium sulfur battery

An electrolyte and electrolyte technology, which is used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, lithium batteries, etc., can solve the problems of low coulombic efficiency of lithium-sulfur batteries, loss of positive active material, and rapid capacity decay, so as to improve the coulombic efficiency and The effect of capacity retention, improved solubility and dissociation, and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

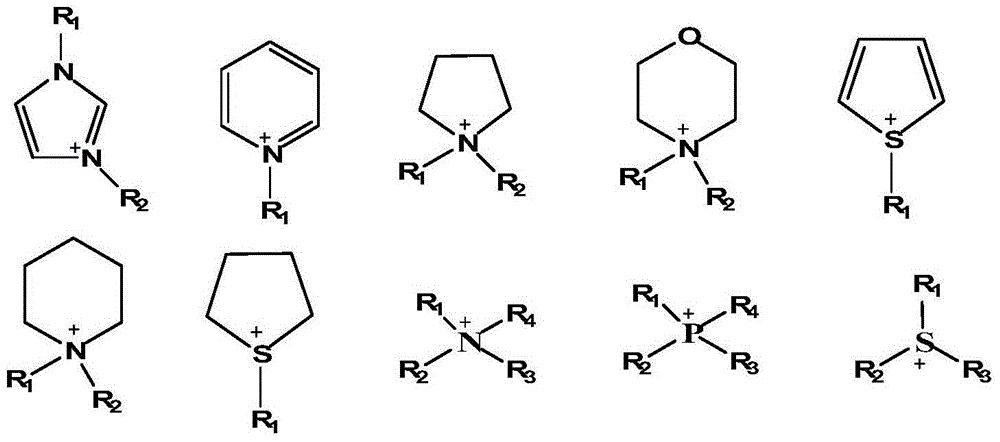

Image

Examples

Embodiment 1

[0026] 1. Preparation of electrolyte materials

[0027] Lithium perfluoroalkylsulfonylimide preparation (L.Conte, et al., J.Fluorine Chem., 2004, 125:243; C. Zhang, et al., Eur.J.Inorg.Chem.2012 :3419). Preparation of ionic liquids containing ether functional groups (Z.Zhou, et al., Chem. Eur. J., 2005, 11:752).

[0028] 2. Preparation of electrolyte

[0029] in an argon atmosphere glove box (H 2 O<1ppm), dissolve 1M lithium trifluoromethylsulfonimide into N,N-diethyl-N,N-bis(methoxyethyl)ammonium-trifluoromethylsulfonimide salt , fully stirred evenly, namely to obtain the lithium-sulfur battery electrolyte (free acid<5ppm, moisture<10ppm) of the present invention.

[0030] 3. Preparation of lithium-sulfur battery

[0031] Place the sulfur-based positive pole piece, the separator, and the lithium metal sheet in the battery case, add the electrolyte solution prepared in this example dropwise, and seal it to prepare a CR2025 button battery.

[0032] 4. Test method for flam...

Embodiment 2-13

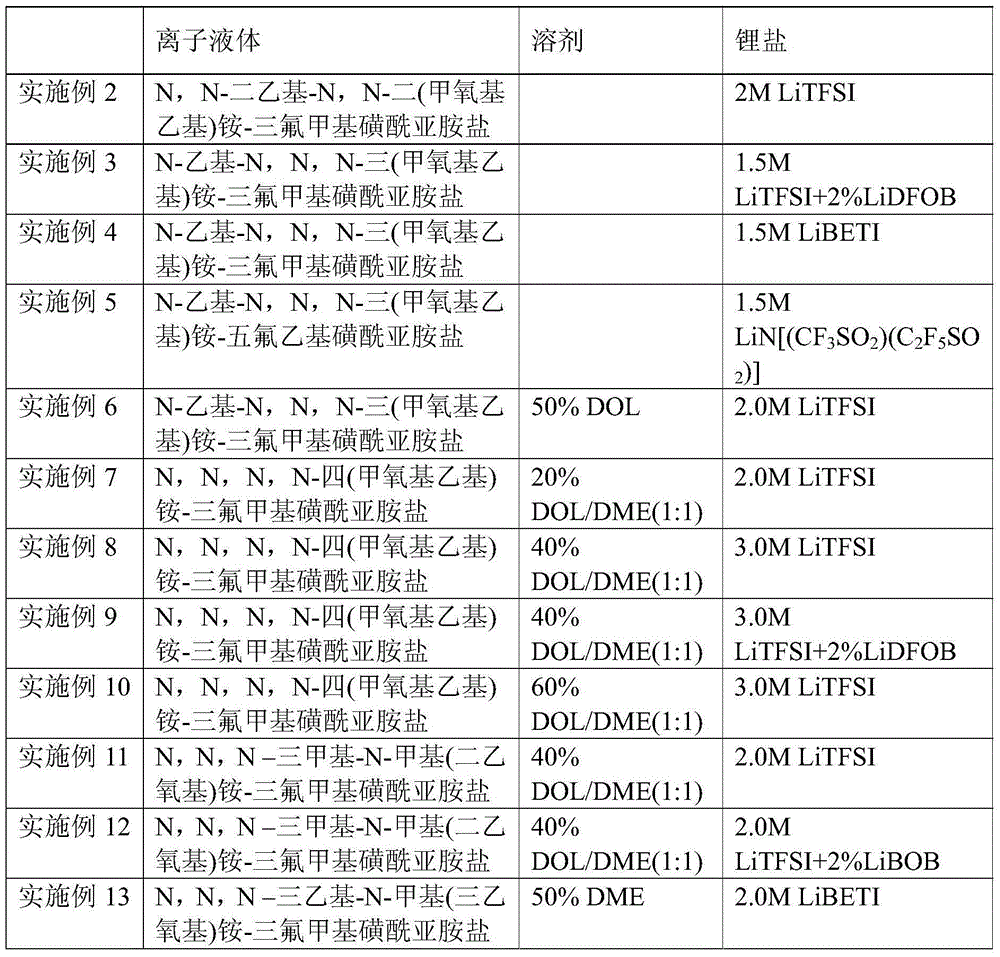

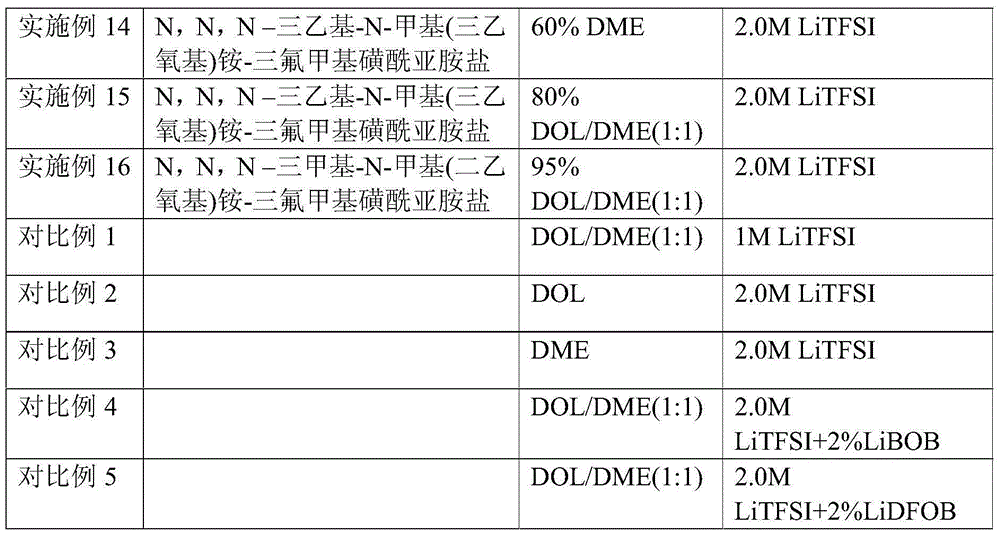

[0037]

[0038]

[0039] The test result of table 2 embodiment and comparative example

[0040]

[0041] The above experimental data show that the electrolyte solution of the present invention has obvious flame retardant function, and the battery using the electrolyte solution obviously has a better capacity retention rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com