Method for preparing copper-tungsten alloy powder

A technology of copper-tungsten alloy and powder, which is applied in the field of materials science, can solve the problems affecting the performance and application of W-Cu composite materials, poor density of copper-tungsten alloy powder, etc., and achieve the advantages of shortened preparation time, large synthesis amount and small investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

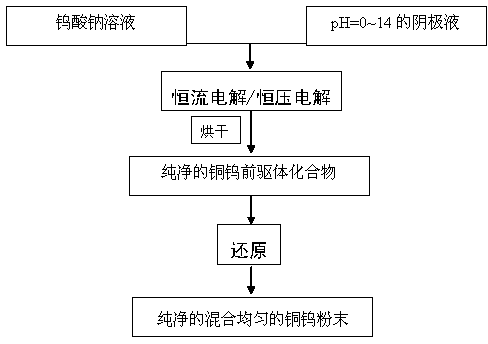

Method used

Image

Examples

Embodiment

[0024] With 95ml of 0.01mol / L sodium tungstate solution as anolyte, 90ml of 0.01mol / L hydrochloric acid solution as catholyte, copper sheet as anode and titanium mesh as cathode, electrolyze 306S at a constant current of 0.6A (electrolysis time is based on Na + The theoretical electricity consumed by all the ions transferred to the cathode chamber is calculated, that is, ), to obtain electrolysis products.

[0025] The anode product obtained by electrolysis was washed three times with deionized water, and then dried in a blast drying oven at a constant temperature of 60° C. for 2 hours to obtain a pure copper-tungsten precursor compound.

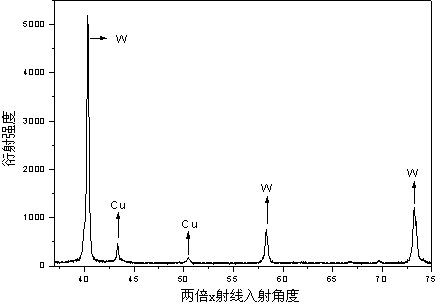

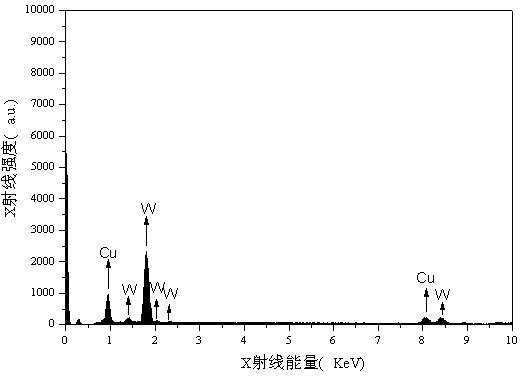

[0026] Put the copper-tungsten precursor compound into a tube furnace and reduce it at 400°C for 2 hours at a heating rate of 2.5°C / min in a hydrogen atmosphere, and then reduce it at 700°C for 5 hours to obtain copper-tungsten alloy powder. The obtained copper-tungsten alloy powder test XRD analysis results are as follows: figure 2 , E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com