Preparation method of nano calcium carbonate/titanium dioxide composite powder with core-shell structure

A nano-calcium carbonate, titanium dioxide technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of low stability of composite particles, large particle size of titanium dioxide, affecting coating effect, etc. The effect of strong absorption capacity, high whiteness value and short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Calcium oxide (CaO) was calcined in a muffle furnace at 800°C for 2 hours; after cooling the calcined CaO, prepare Ca(OH) with a mass fraction of 7%. 2 solution, that is, take 5.6g CaO and add it to 500mL water for 12 hours; take a 200-mesh sieve to filter the digested solution, and take the filtrate for later use. Place the filtrate in a cold water bath to keep its temperature lower than 19°C; take the filtrate and place it in a large-mouth quartz tube, check the connection line, and first pass through the N 2 CO 2 , into N 2 The gas flow rate is 60L / h, and CO 2 The flow rate of the gas is 30L / h. After the gas is stably reacted, the gas flow rate can be increased to ensure that V N2 :V CO2 = 2:1; when the pH of the reactant is detected by pH test paper = 7, the flow rate is lowered at this time, V N2 =60L / h, V CO2 =30L / h, when the pH=6 is the end of the reaction, at this time, the gas is closed, and the CO is closed first 2 , after closing N 2 gas, the prepared...

Embodiment 2

[0039] Dissolve 0.072g of titanium sulfate 1 in 10g of distilled water 1 to obtain an impregnating solution; add 1g of calcium carbonate to the impregnating solution, vibrate at room temperature for 30min, then filter with suction, wash with distilled water until the filtrate is washed with BaCl 2 Detect that no precipitation is generated, and the pre-product is obtained; 2.88g of titanium sulfate 2 is dissolved in 10.92g of distilled water 2 to obtain an aqueous solution of titanium sulfate; 0.8g of the pre-product and 6g of urea are dissolved in 44.5g of distilled water 3, and 0.0020g of dodecane is added Sodium phenylsulfonate, at 80°C under stirring conditions, add the titanium sulfate aqueous solution dropwise, control the flow rate of the titanium sulfate aqueous solution to about 4mL / h, continue the reaction for 30-60min after the dropwise addition, stop the reaction, and cool , suction filtration, washing until the filtrate was washed with BaCl 2 No precipitation was d...

Embodiment 3

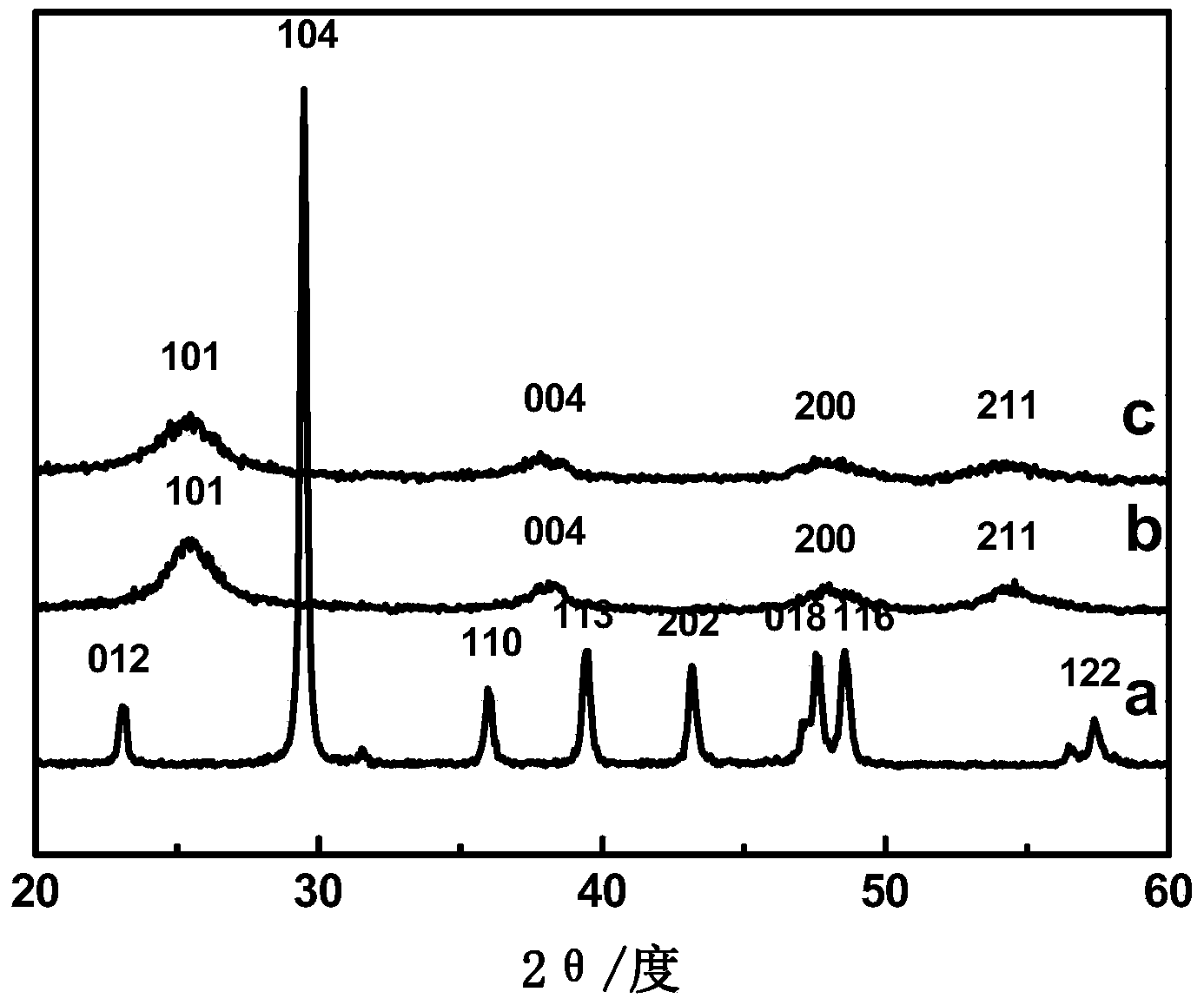

[0044] Change the amount of titanium sulfate 1 to 0.288g to prepare the impregnating solution, change the amount of distilled water 1 to 19.7g, change the amount of sodium dodecylbenzenesulfonate to 0.0010g, and use 90°C as the reaction temperature. The amount of 2 was changed to 1.68g, and the amount of distilled water 2 was changed to 6.37g to prepare an aqueous solution of titanium sulfate, and the rate of addition was adjusted to 2mL / h instead, and Example 2 was repeated to obtain nano-CaCO with a core-shell structure. 3 / TiO 2 Composite powder, its XRD pattern is shown in Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com