Method for preparing semimetallic state conductive titanium black nano-tube array

A technology of nanotube array and conductive titanium oxide, which is applied in the direction of nanotechnology, can solve the problems of difficult electron transfer, harsh conditions, restrictions, etc., and achieve the effect of overcoming difficult control conditions, mild reaction conditions, and changing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

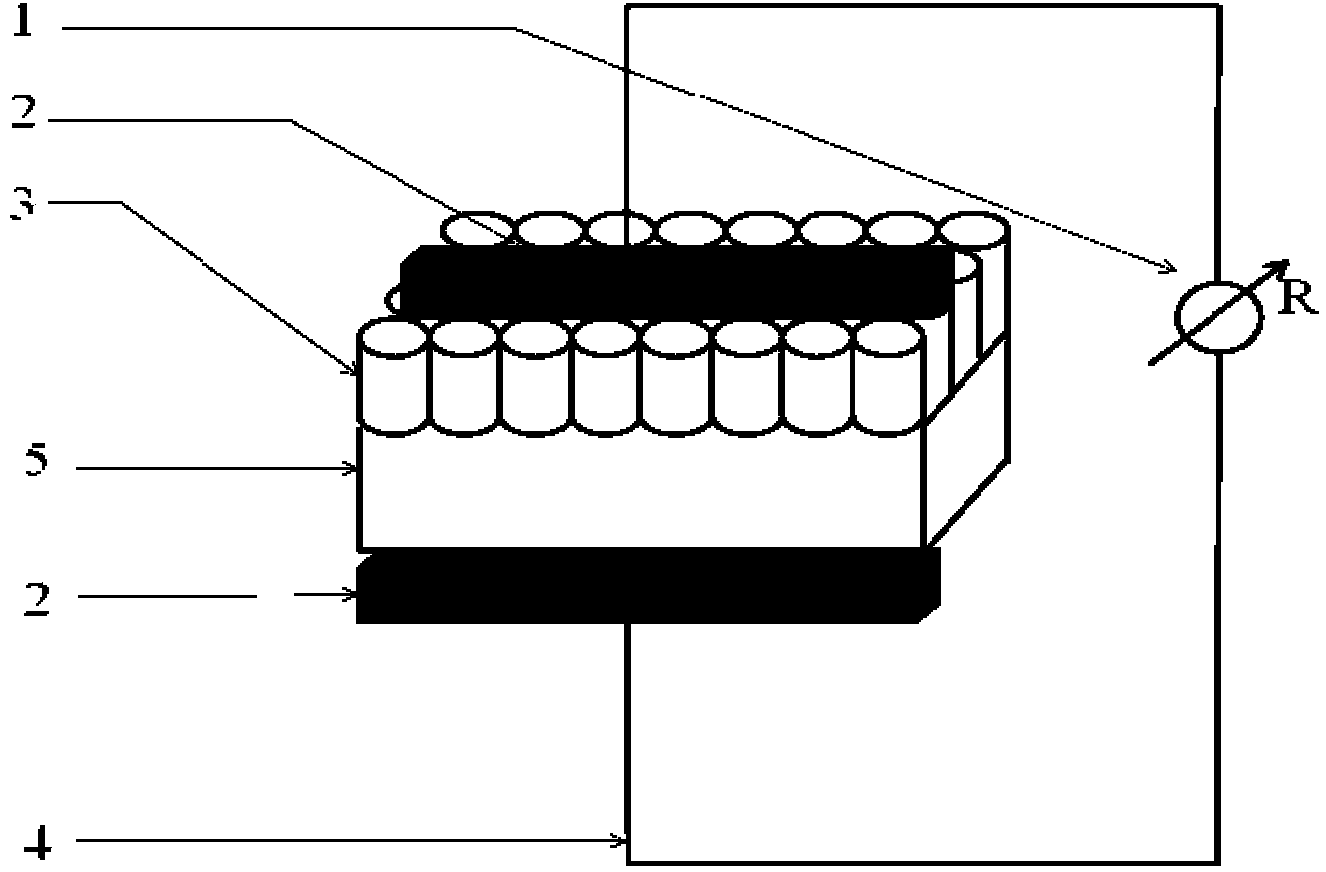

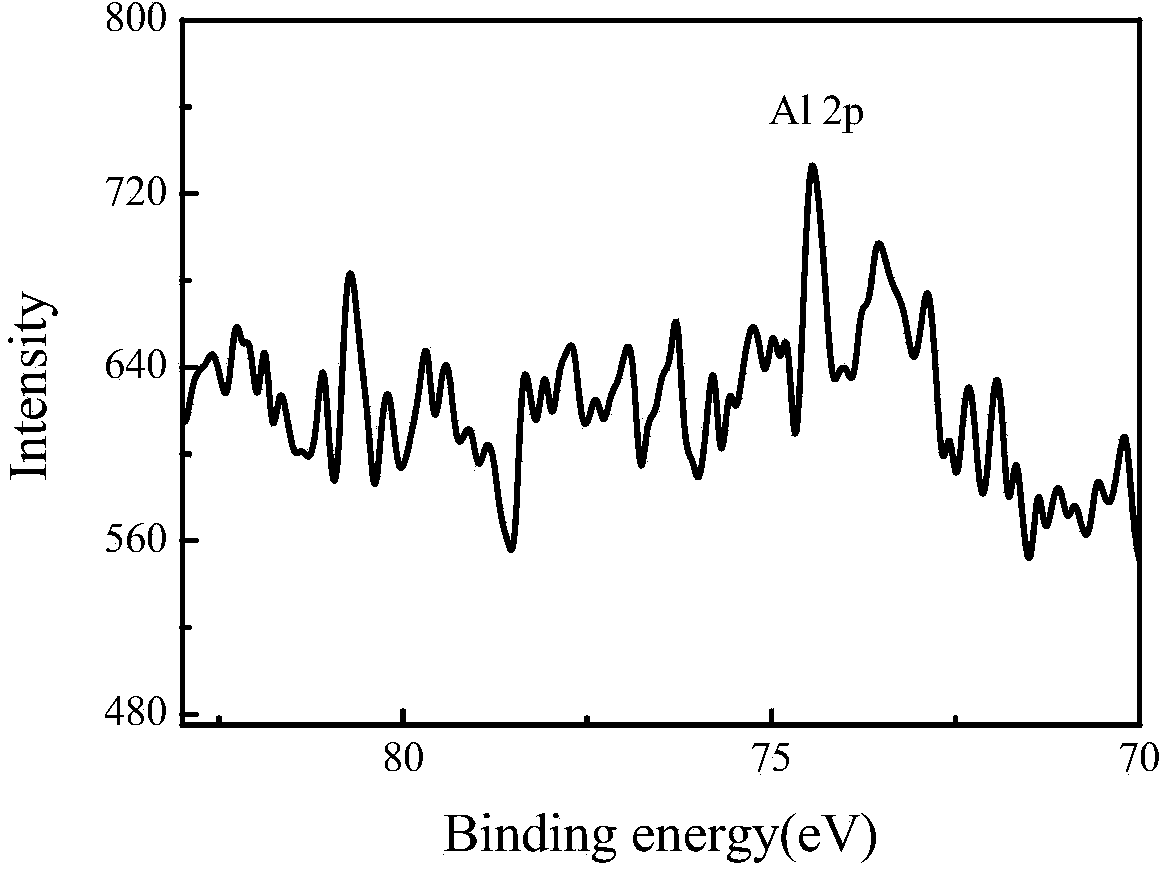

[0027] The titanium sheet is used as the anode, the platinum electrode is used as the cathode, the electrolyte is an ethylene glycol organic system (0.3%wt ammonium fluoride, 4%vol deionized water and 96%vol ethylene glycol solution), and a DC voltage of 40V is applied. Under stirring conditions, anodize for 4 hours, then ultrasonically peel off the nano-titanium dioxide film from the first anodic oxidation, and then perform the second anodic oxidation according to the process conditions and electrolyte of the first anodic oxidation, and the second oxidation time is 1 hour. Then, the prepared nano-titanium dioxide sample is washed with distilled water and dried in nitrogen to obtain a titanium dioxide nanotube array with uniform distribution, orderly arrangement and uniform tube diameter. Then heat-treat the prepared titanium dioxide nanotube array at 350° C. for 3 hours to obtain anatase titanium dioxide nanotube array with complete crystal form. Measure its resistance with a...

Embodiment 2

[0029] The titanium sheet is used as the anode, the platinum electrode is used as the cathode, the electrolyte is an ethylene glycol organic system (0.3% wt ammonium fluoride, 4% vol deionized water and 96% vol ethylene glycol solution), and a DC voltage of 60V is applied. Under stirring conditions, anodize for 3 hours, then ultrasonically peel off the nano-titanium dioxide film anodized for the first time, and then perform the second anodic oxidation according to the process conditions and electrolyte of the first anodic oxidation, and the second anodic oxidation for 1 hour. Then, the prepared nano-titanium dioxide sample was washed with distilled water and dried in nitrogen to obtain a titanium dioxide nanotube array with uniform distribution, orderly arrangement and uniform tube diameter, and its resistance was measured by a multimeter to be greater than 20 MΩ. Then heat-treat the prepared titanium dioxide nanotube array at 450° C. for 2 hours to obtain anatase titanium diox...

Embodiment 3

[0031] The titanium sheet is used as the anode, the platinum electrode is used as the cathode, the electrolyte is an ethylene glycol organic system (0.3% wt ammonium fluoride, 4% vol deionized water and 96% vol ethylene glycol solution), and a DC voltage of 80V is applied. Under stirring conditions, anodize for 2 hours, then ultrasonically peel off the nano-titanium dioxide film from the first anodic oxidation, and then perform the second anodic oxidation according to the process conditions and electrolyte of the first anodic oxidation, and anodize for 1 hour. Then the prepared nano-titanium dioxide sample was washed with distilled water and dried in nitrogen to obtain a titanium dioxide nanotube array with uniform distribution, orderly arrangement and uniform tube diameter. The resistance was measured by a multimeter to be greater than 21MΩ. Then heat-treat the prepared titanium dioxide nanotube array at 500° C. for 1.5 hours to obtain anatase titanium dioxide nanotube array w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com